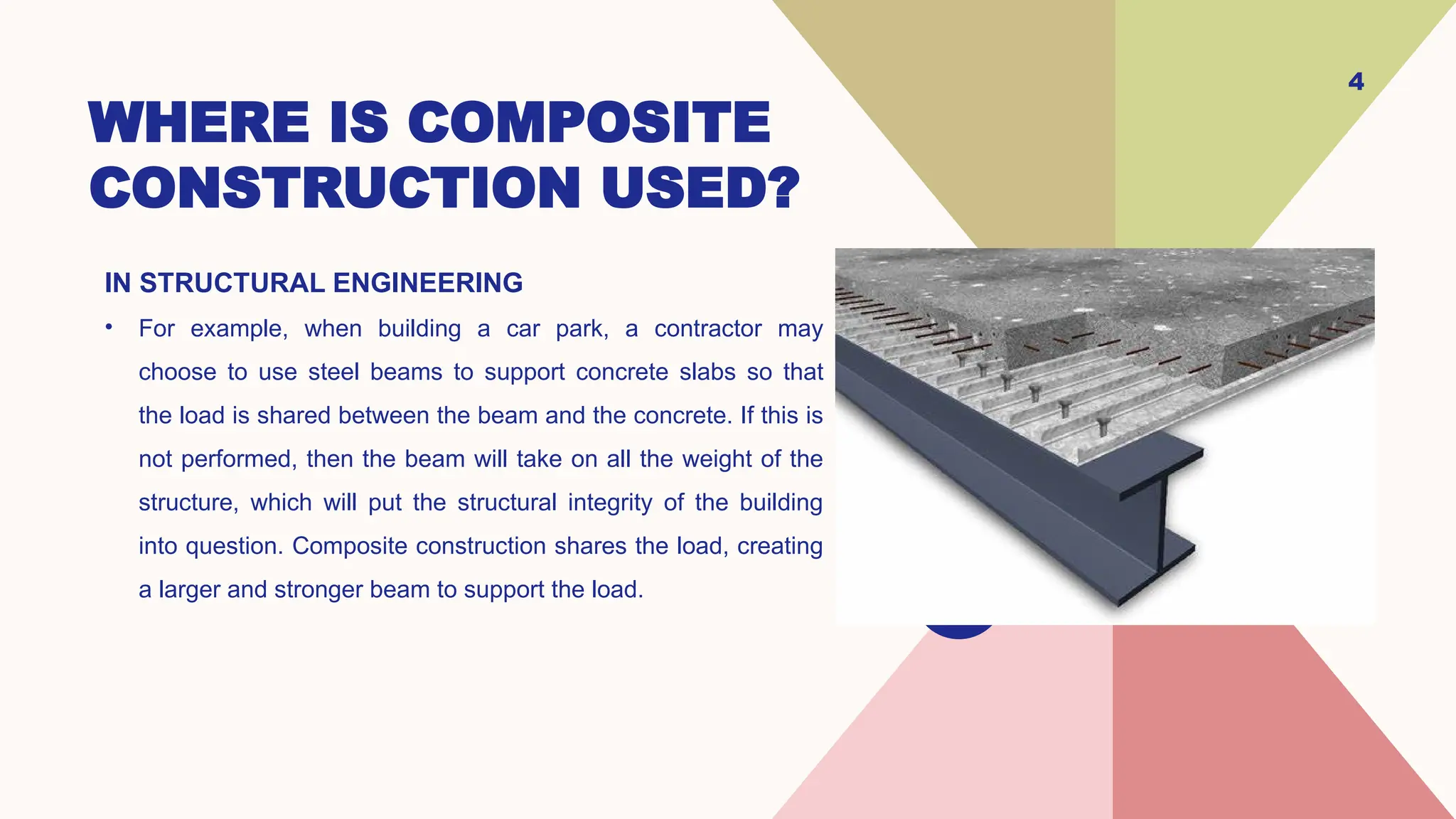

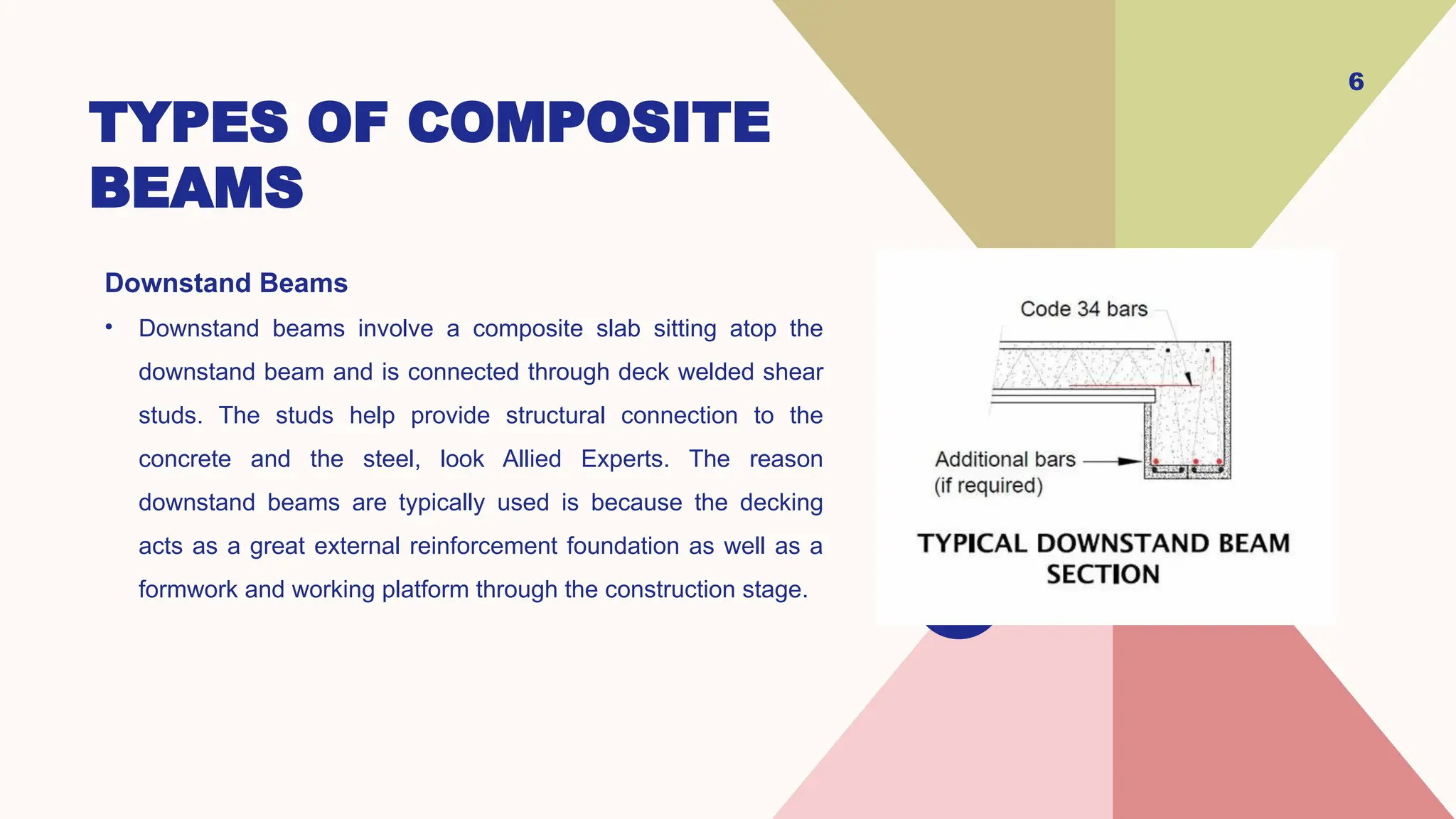

Composite construction involves using multiple materials to create structurally sound buildings, commonly seen in large commercial projects like car parks and warehouses. Key materials include reinforced concrete, fiber-reinforced polymers, and steel-concrete composite beams, which allow for shared loads and increased structural integrity. Advantages of composite construction include a high strength-to-weight ratio, durability, and long-term cost-effectiveness.