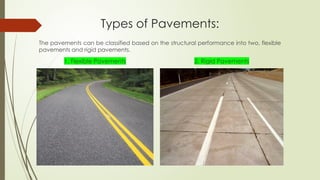

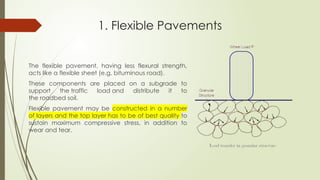

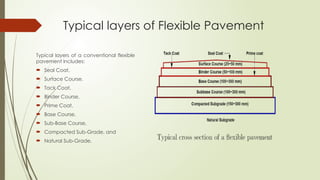

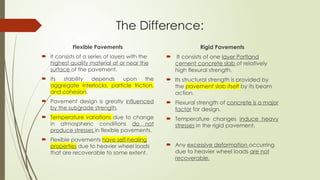

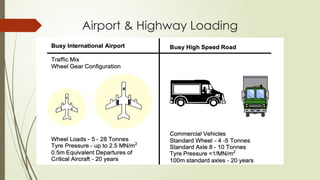

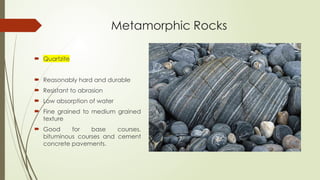

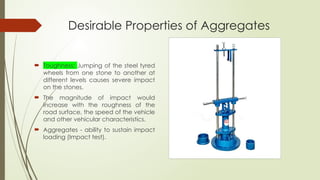

The document provides a comprehensive overview of pavement analysis and design, detailing the definitions, requirements, and types of pavements, including flexible and rigid pavements. It covers the materials used in pavement construction, emphasizing the characteristics and desirable properties of aggregates, bitumen, and binders. Additionally, it discusses the comparison between highway and airport pavements in terms of loading and material specifications.