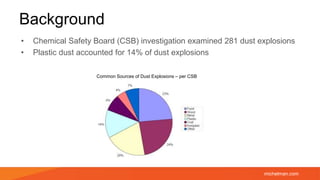

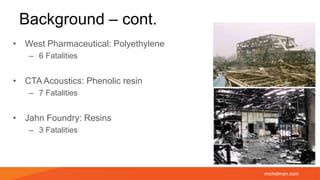

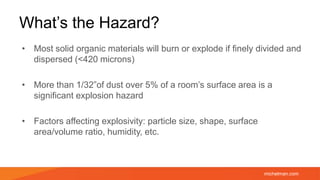

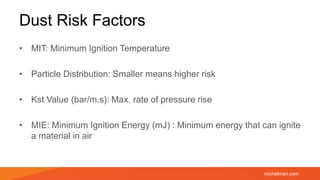

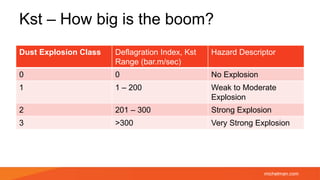

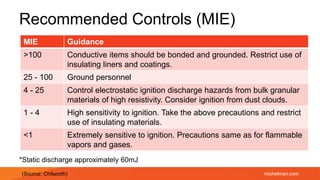

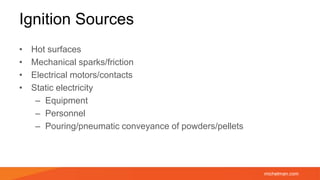

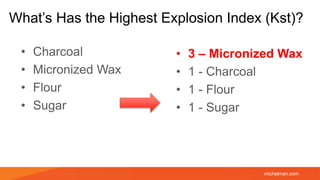

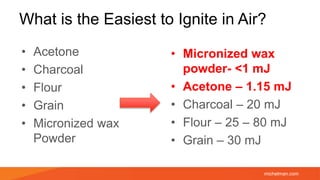

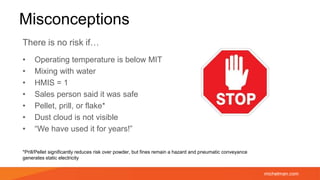

The document provides an overview of dust explosion hazards, including key statistics and risk factors associated with combustible dust. It outlines essential control measures and safety protocols for handling materials prone to dust explosions, emphasizing the importance of proper ventilation and ignition control. The document also addresses common misconceptions surrounding dust risk and highlights the need for effective housekeeping and maintenance practices.