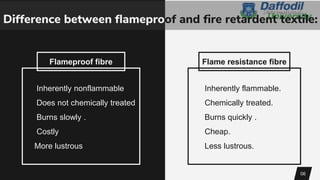

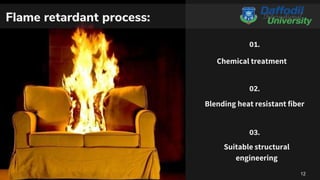

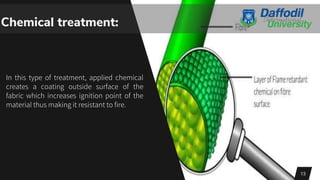

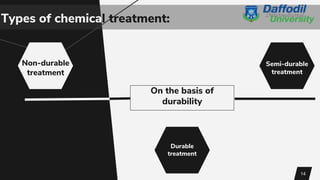

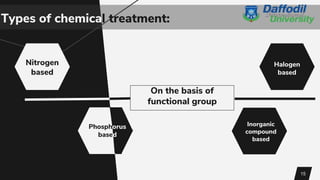

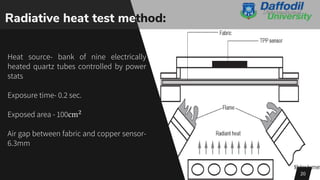

This document provides information about flame retardant and flame proof textiles. It discusses the difference between flameproof textiles, which are inherently resistant to burning, and flame retardant textiles, which are treated with chemicals to resist burning. The document outlines various flame retardant chemical treatment processes and testing methods used to evaluate flame resistance. It notes some limitations of flame retardant textiles and concludes by emphasizing the importance of flame resistance for safety.