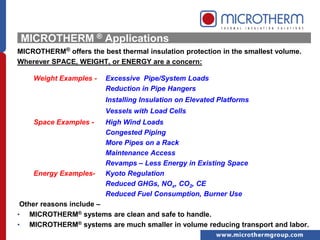

Microporous insulation is a highly effective thermal insulation material made of amorphous silica and metal oxide powders pressed into rigid or flexible panels, blankets, or pipe sections. It has the lowest thermal conductivity of any high temperature insulation, making it an excellent choice for applications where space, weight, or energy loss are concerns. Microporous insulation is safe and easy to fabricate and install, and it provides significant benefits over traditional insulation materials.