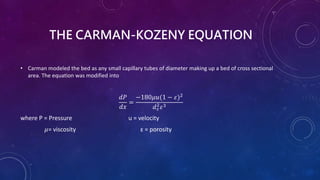

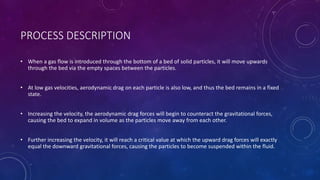

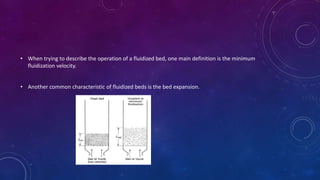

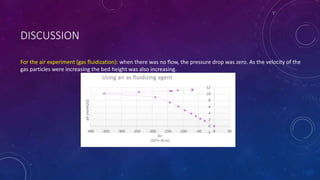

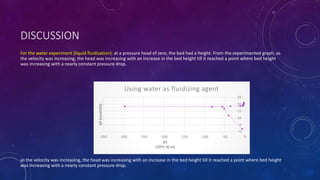

Fixed bed fluidization can be classified as particulate or bubbling, depending on if it occurs in liquids or gases. As gas velocity increases through a solid particle bed, drag forces counteract gravity and cause the bed to expand. At a critical velocity, particles are uniformly suspended and minimum fluidization occurs. Industrial applications include fluidized bed reactors and dryers where heat and mass transfer are improved over fixed beds. Experiments showed relationships between pressure drop and velocity confirm theoretical equations in both gas and liquid fluidization.