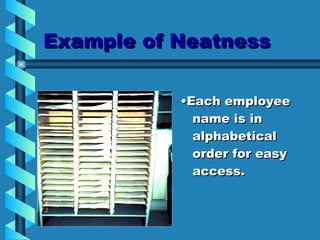

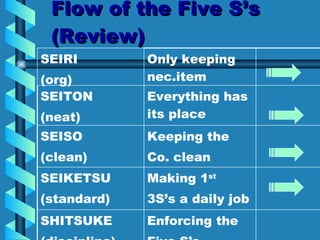

The Five S's are a quality improvement technique used to establish and maintain organization in a company. It consists of five Japanese words - Seiri, Seiton, Seiso, Seiketsu, and Shitsuke - which translate to Organization, Neatness, Cleaning, Standardization, and Discipline. Implementing the Five S's improves efficiency, appearance, and self-organization. An example is provided of how United Electric saw real benefits from applying this process.