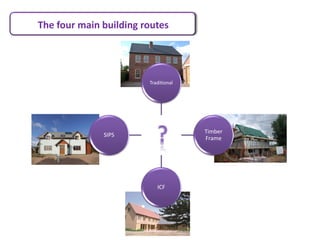

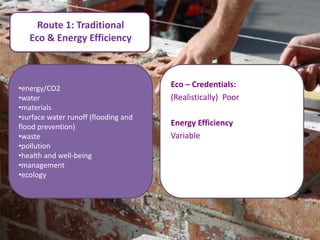

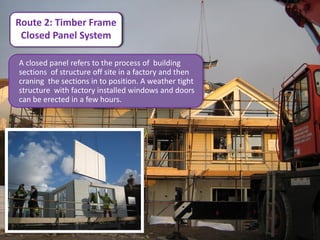

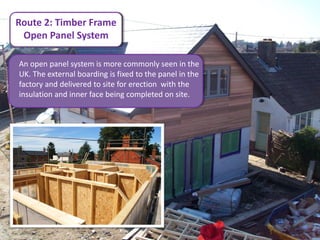

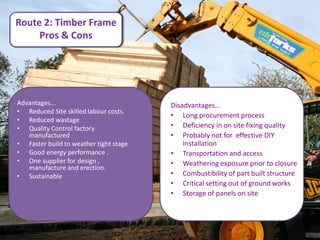

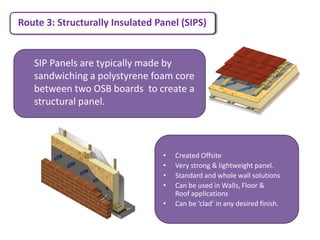

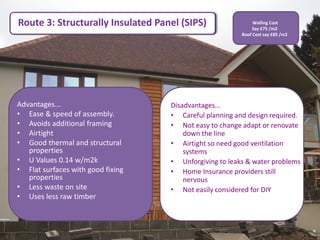

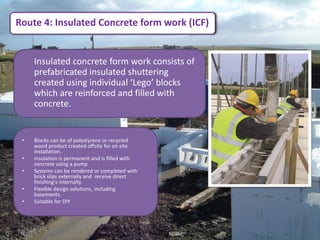

The document outlines various building methods for constructing homes, including traditional, timber frame, structurally insulated panels (SIPs), and insulated concrete formwork (ICF), each with distinct pros and cons regarding efficiency, cost, and craftsmanship. Key factors to consider when choosing a building method include hands-on involvement, experience, energy efficiency, aesthetics, budget, and site constraints. Each method presents unique advantages such as speed of construction or reduced labor costs, but also notable disadvantages such as susceptibility to weather, design limitations, or issues with onsite assembly.