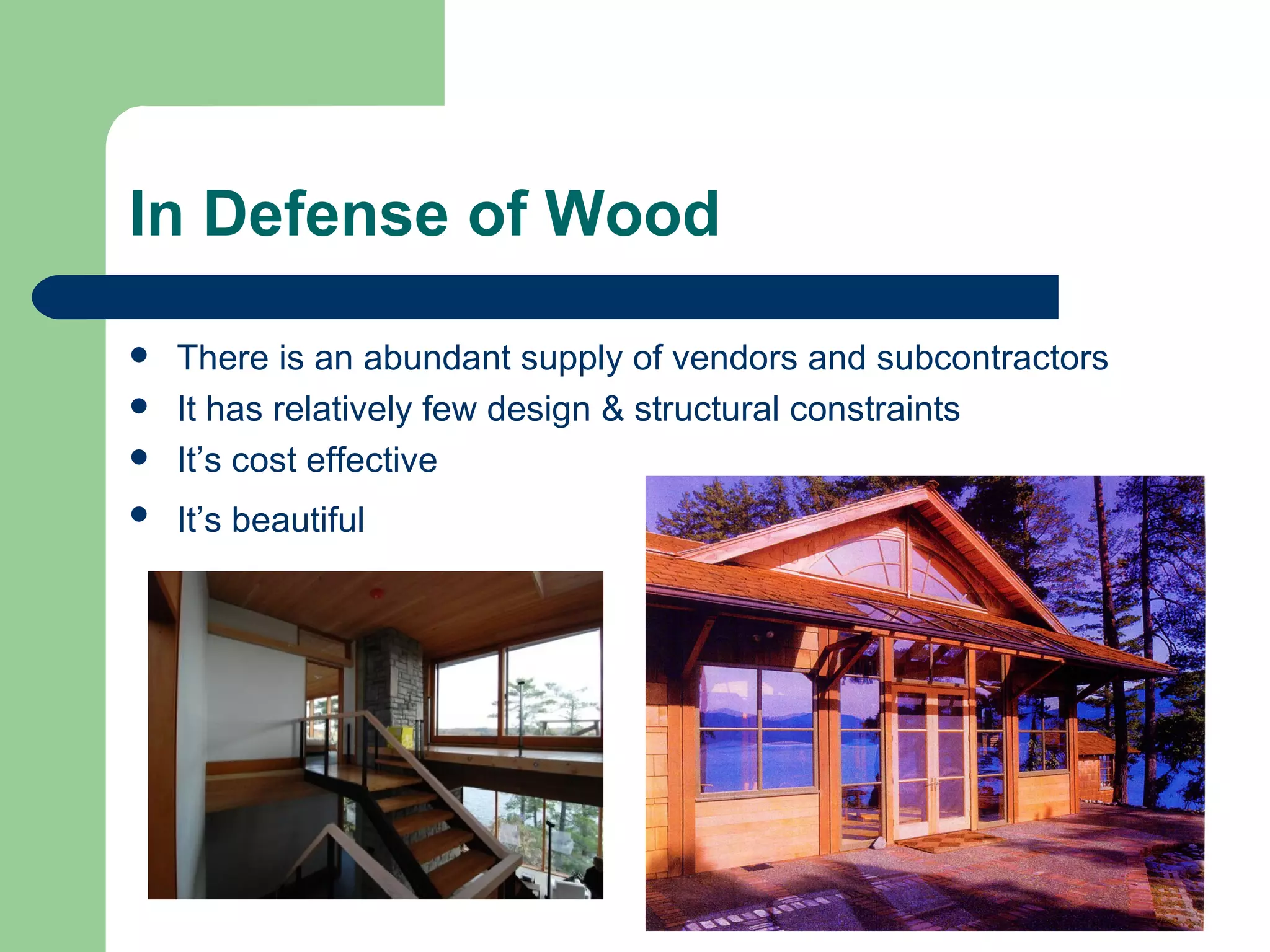

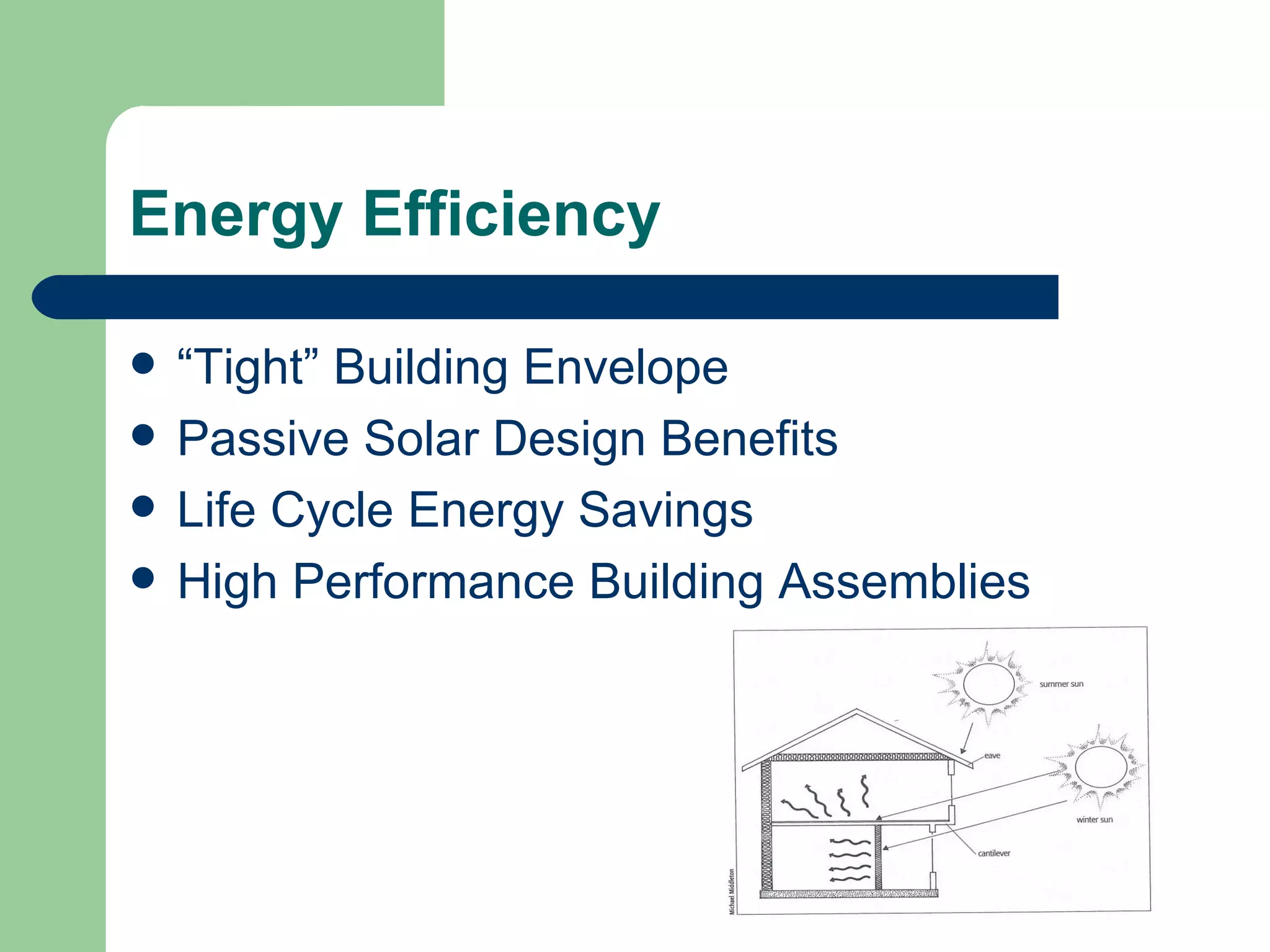

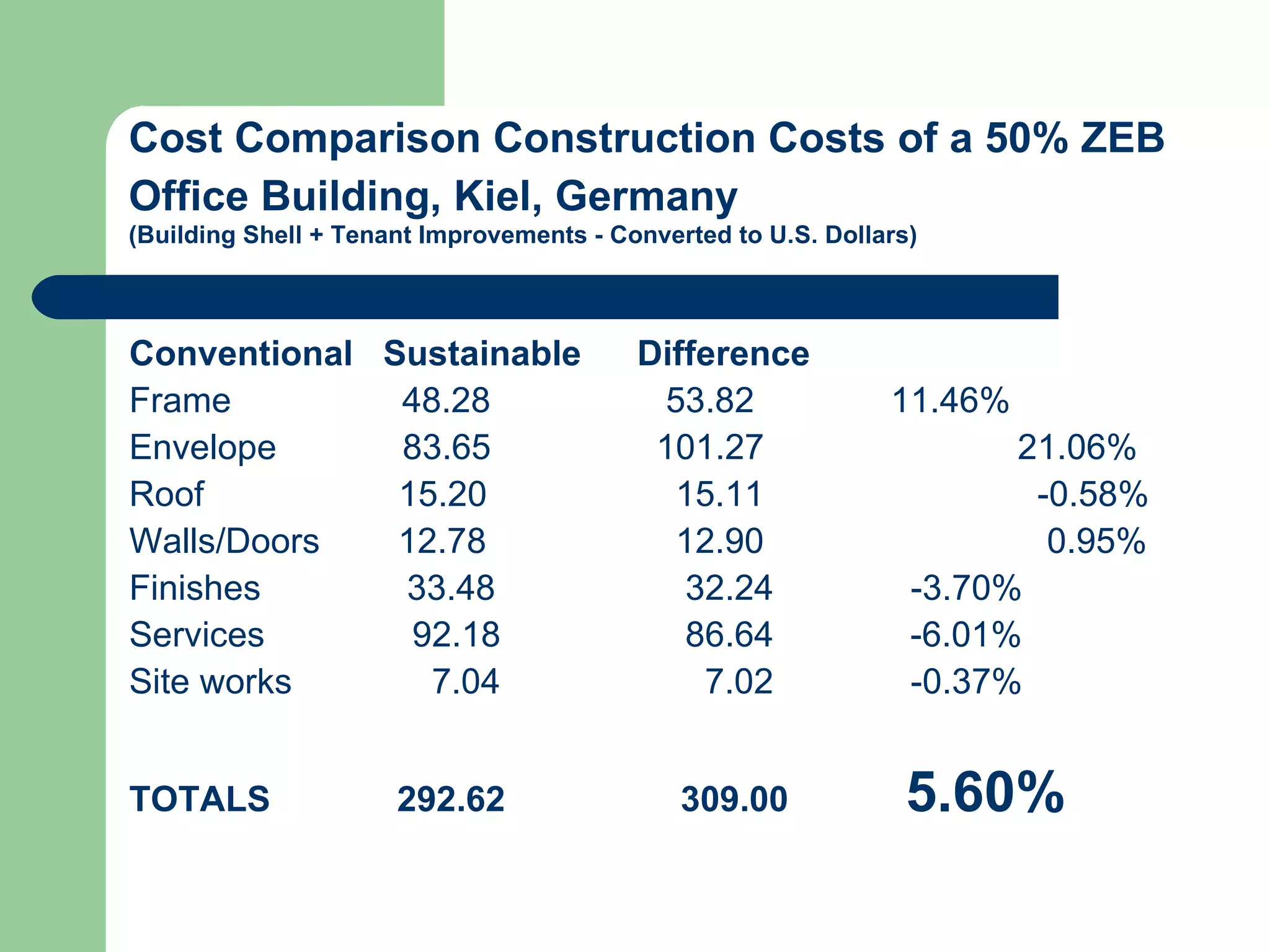

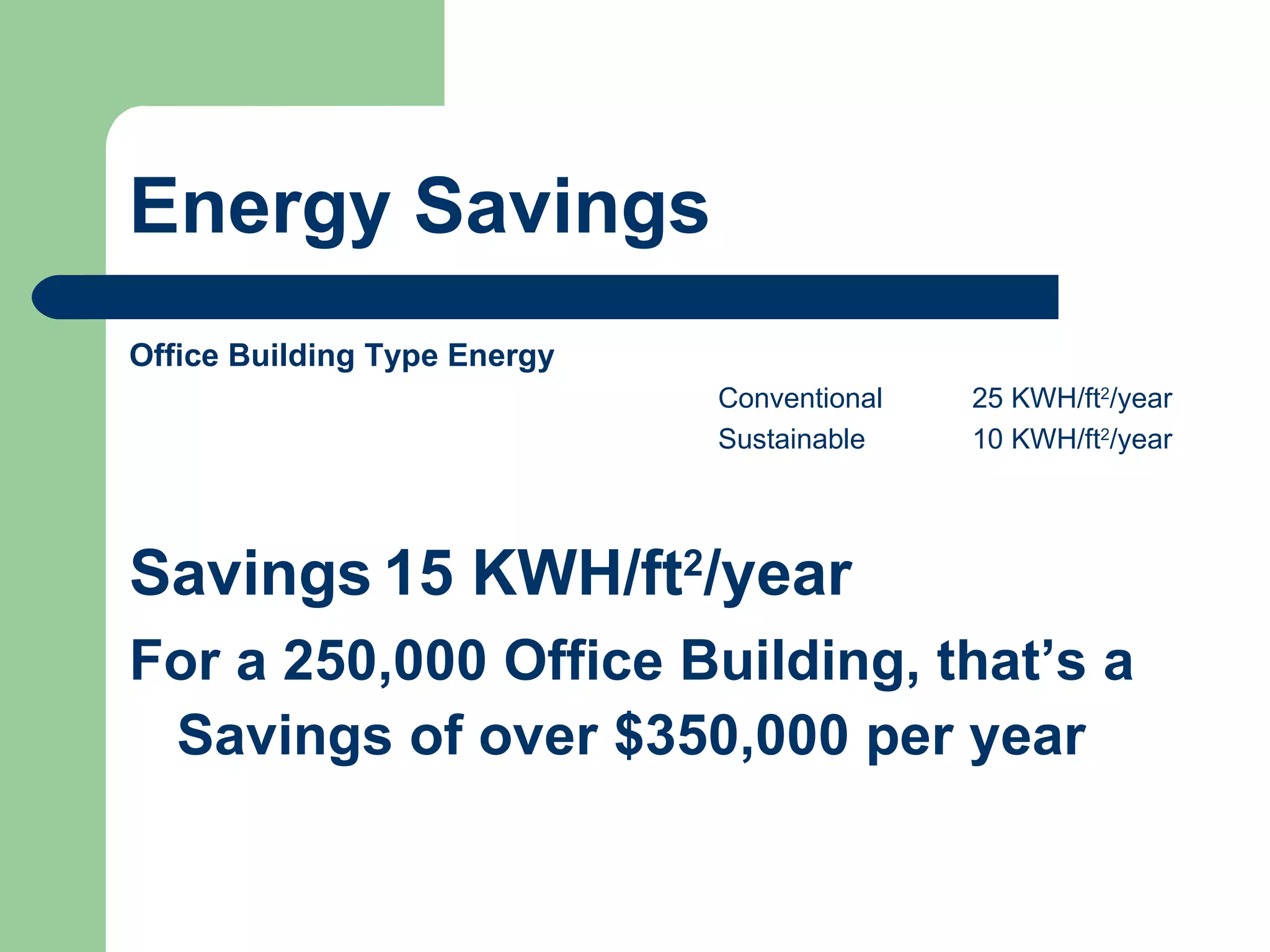

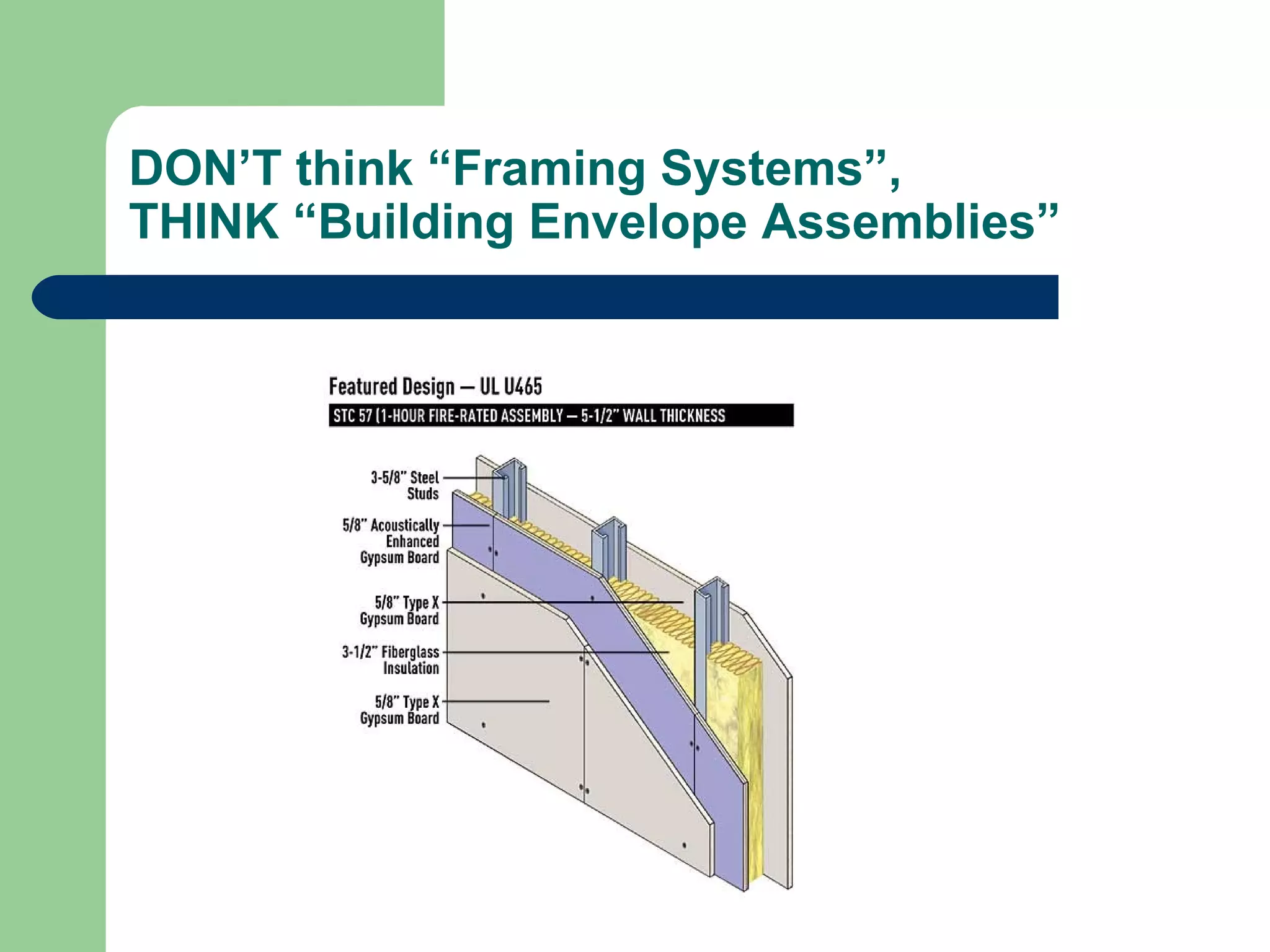

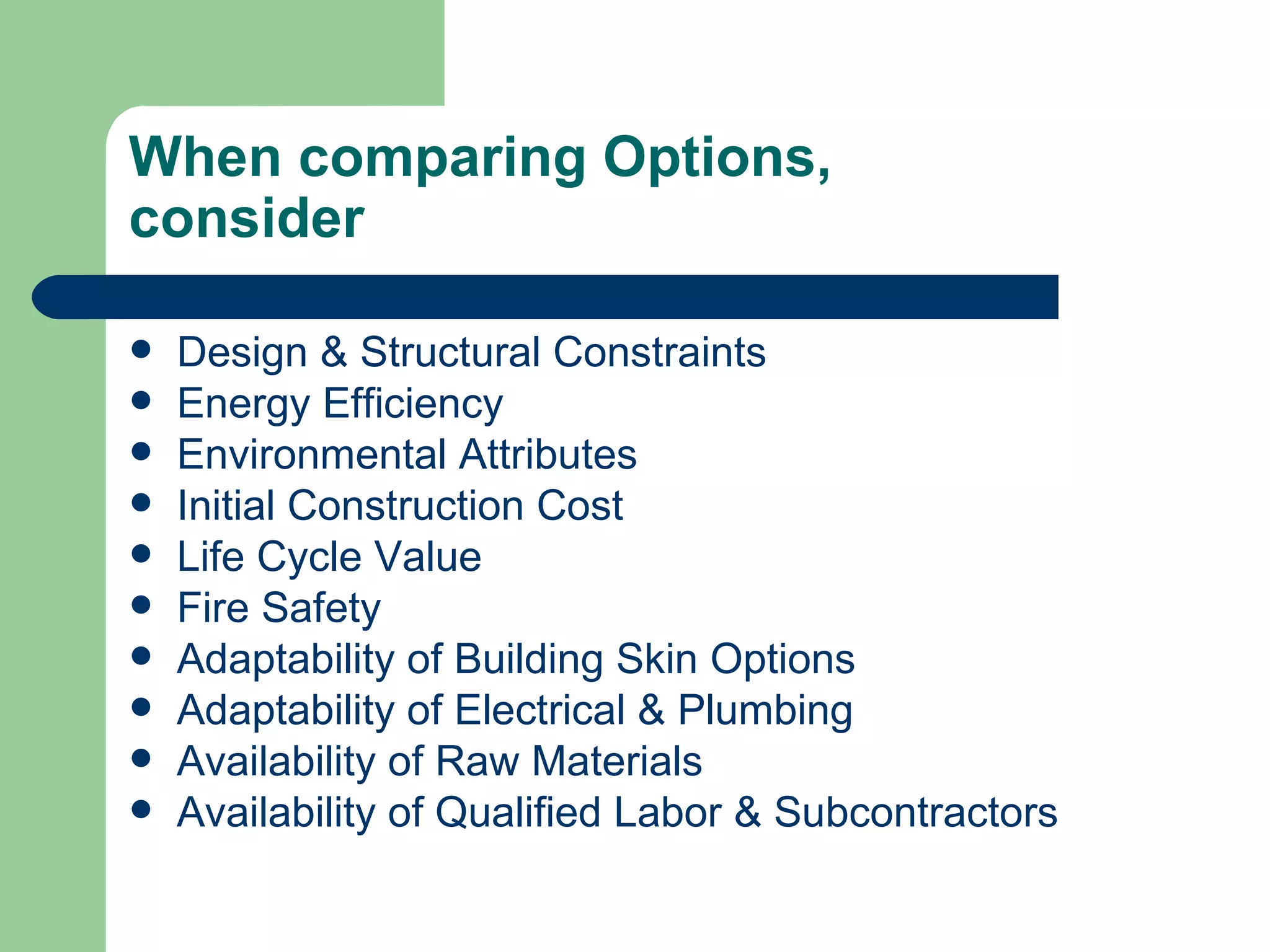

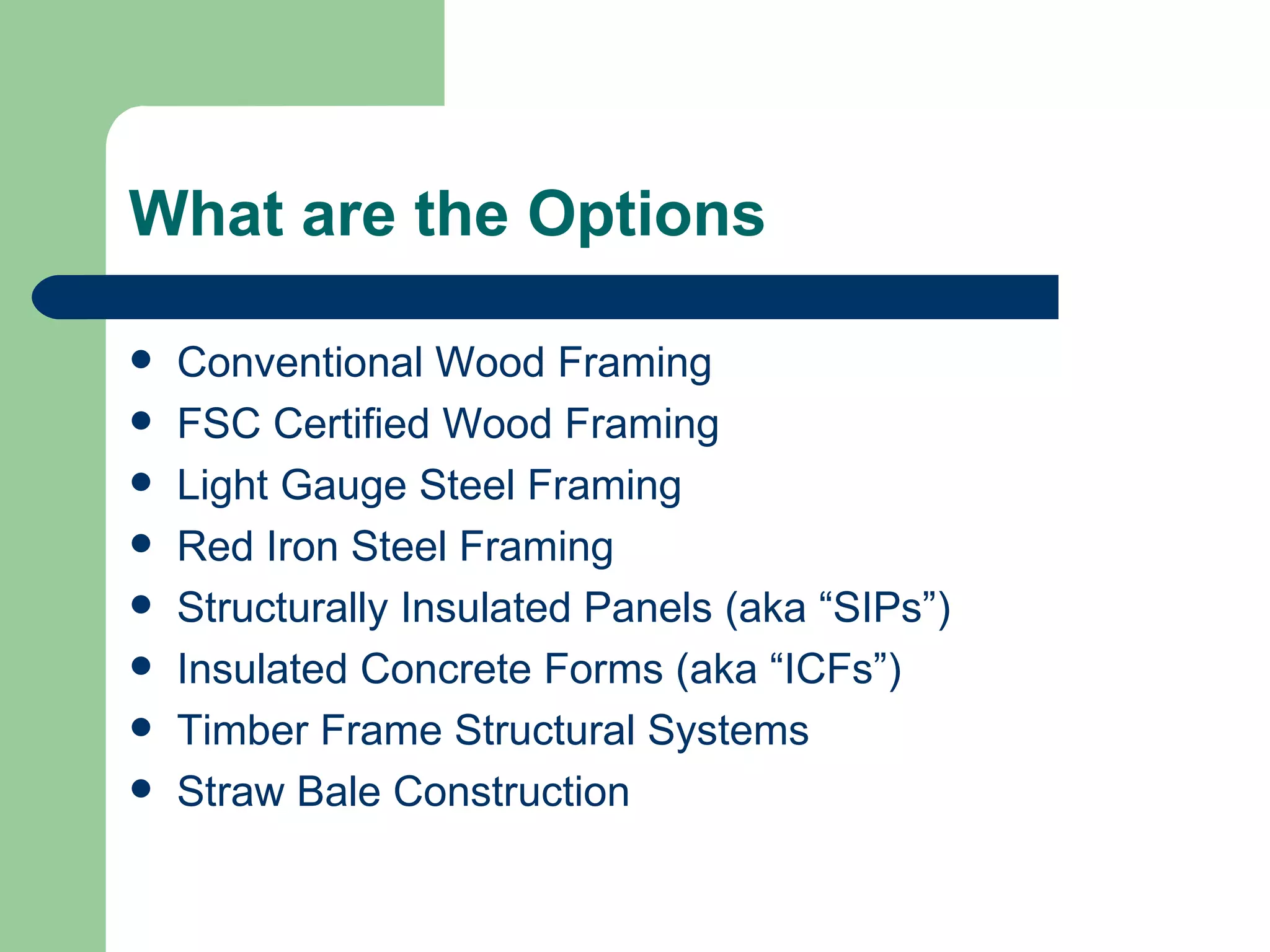

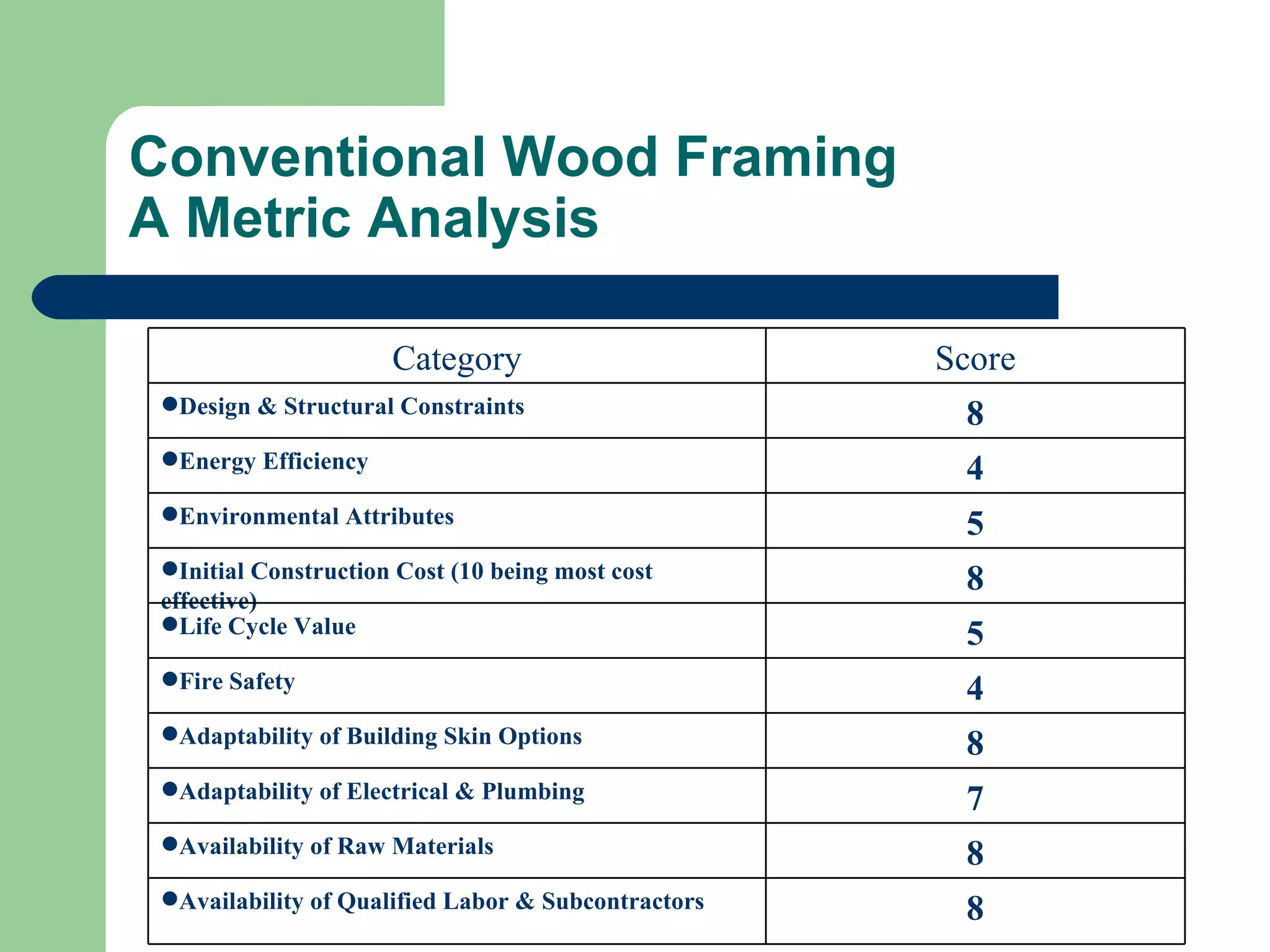

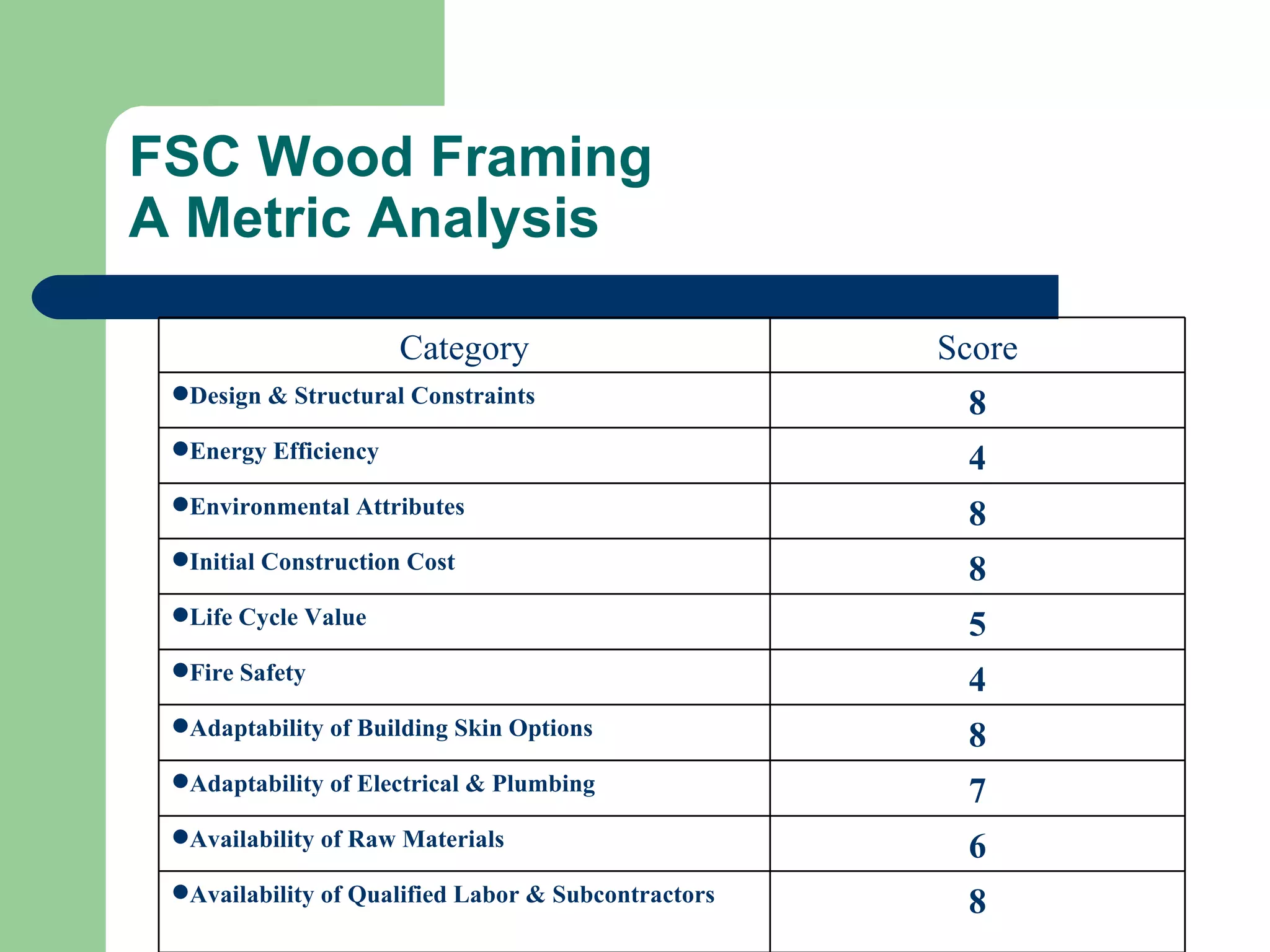

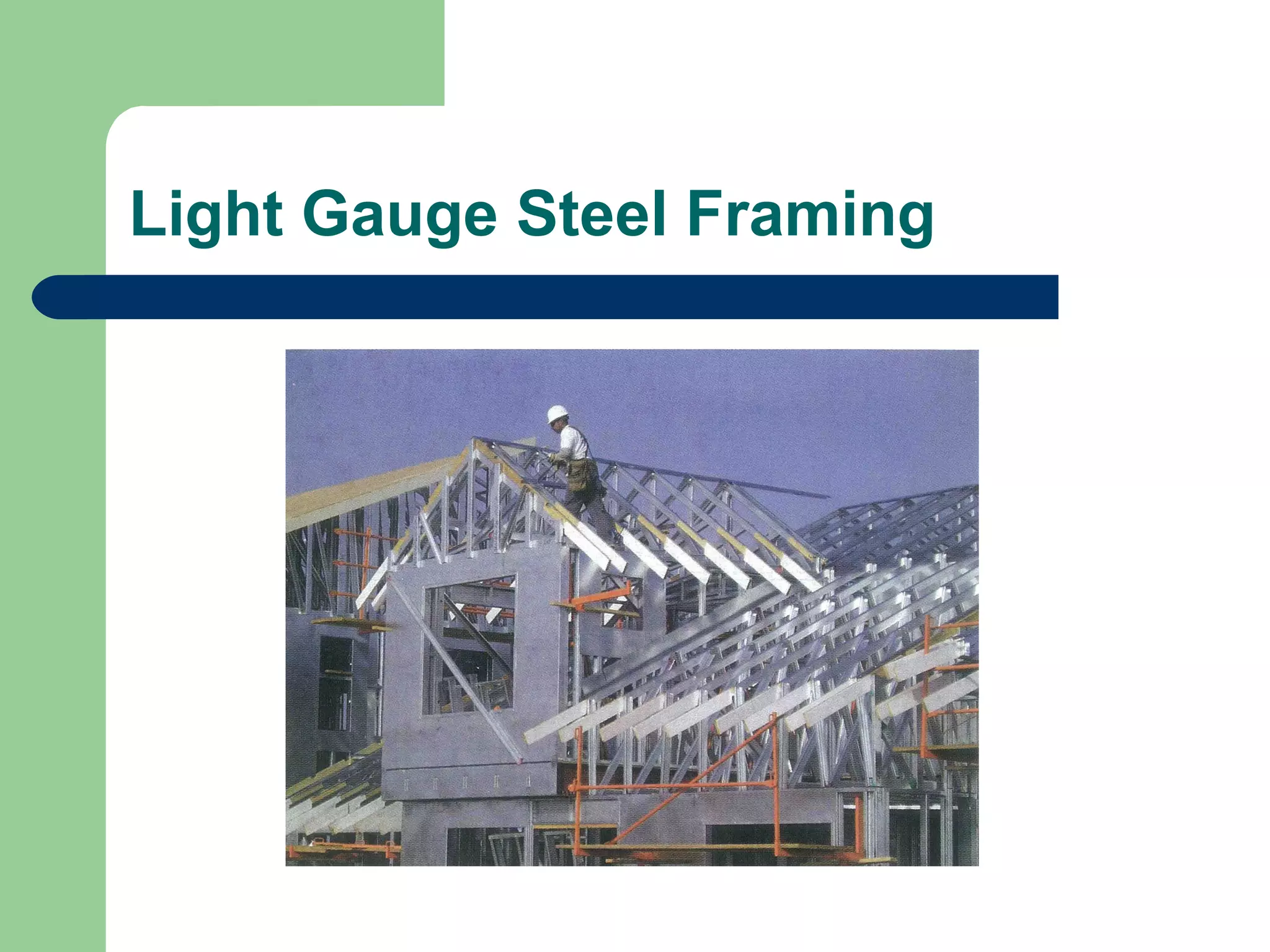

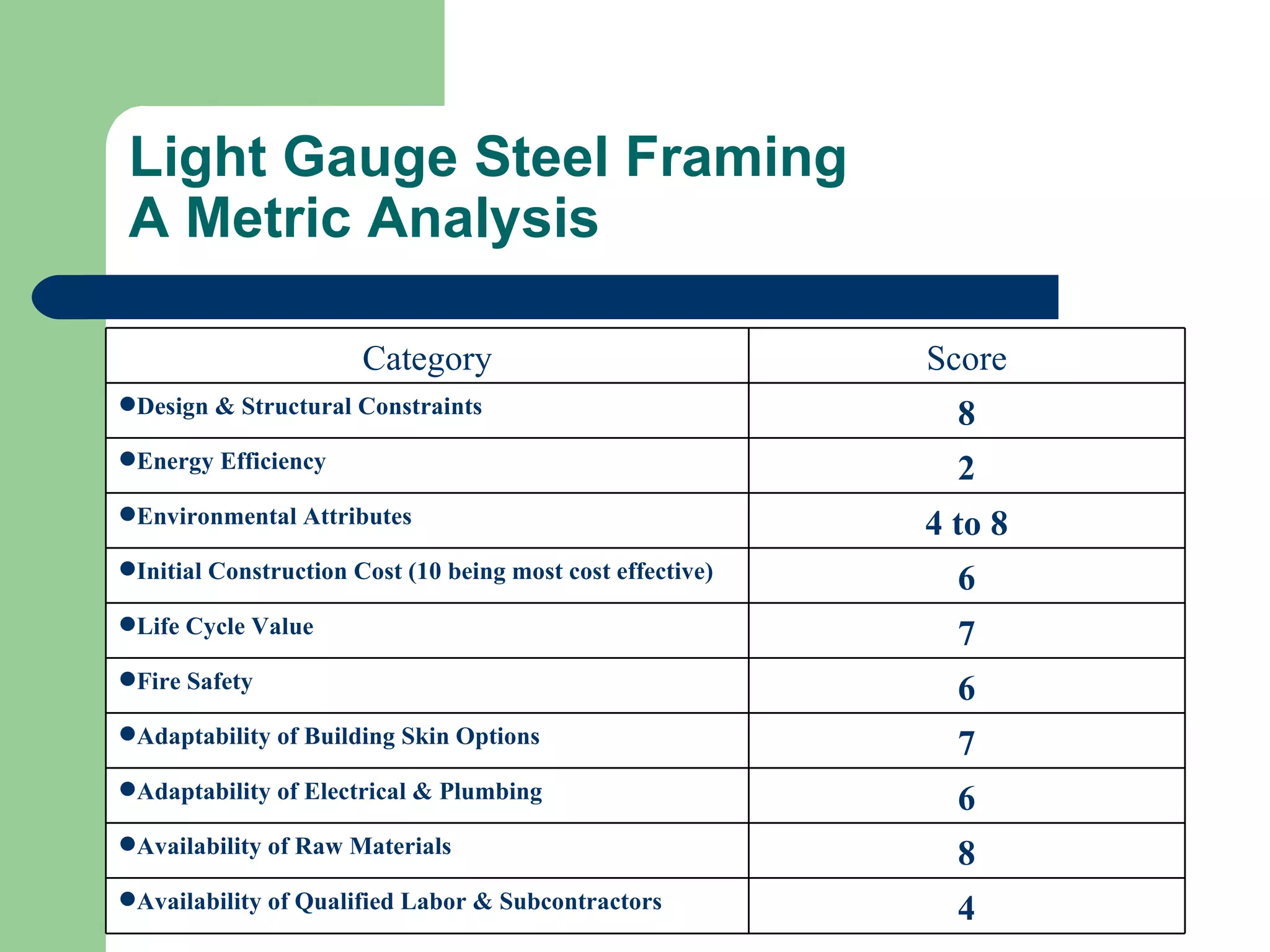

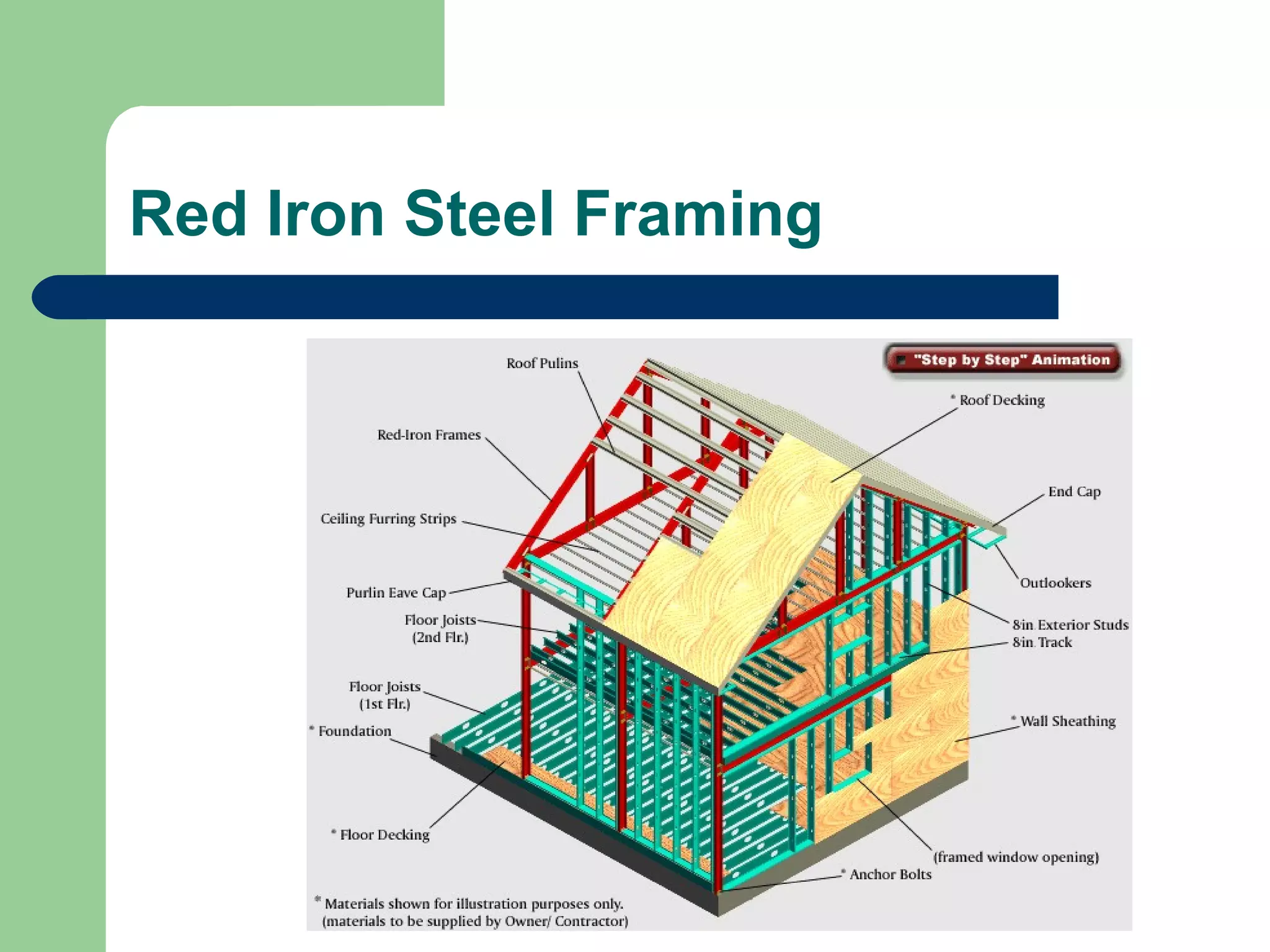

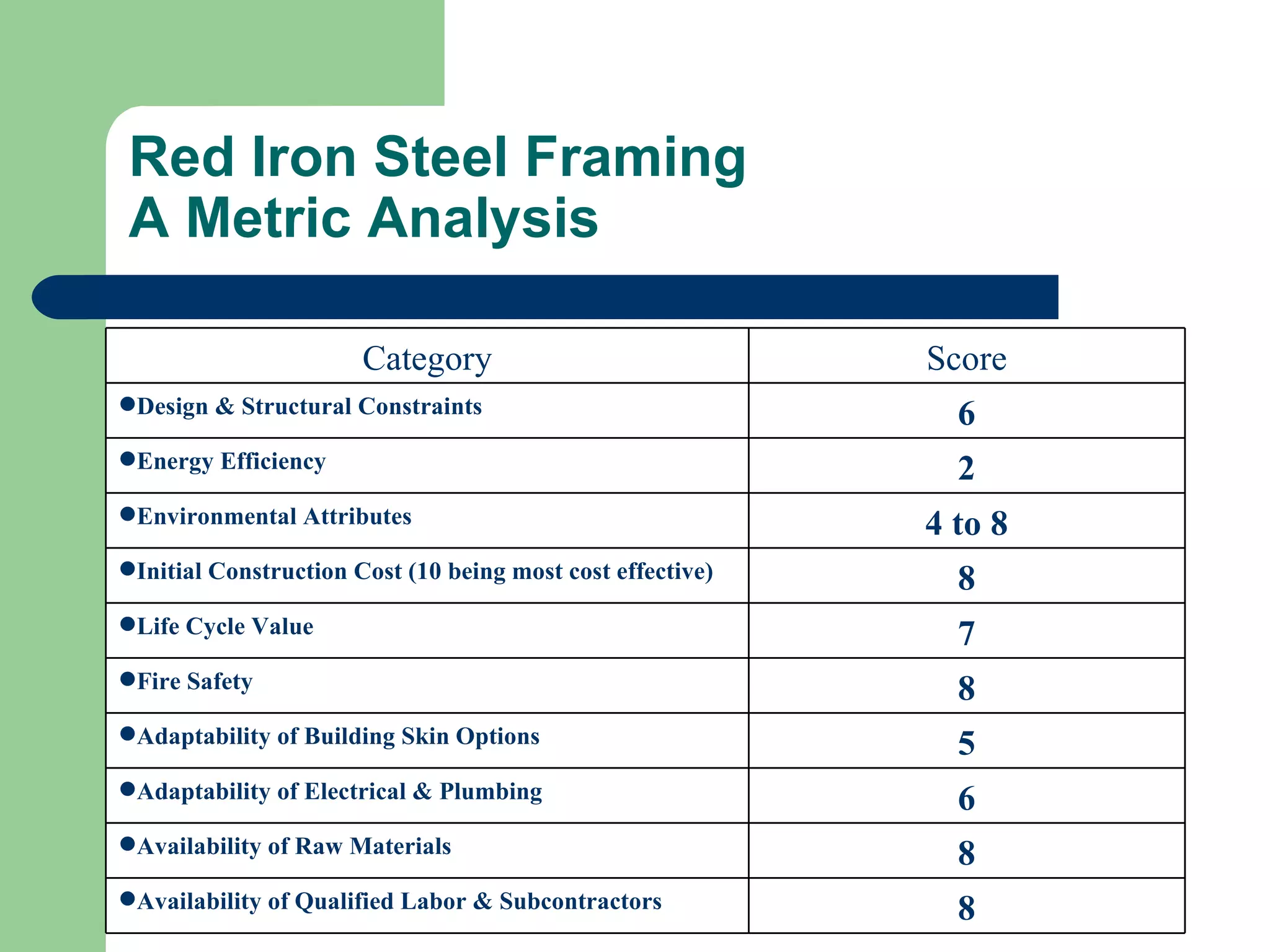

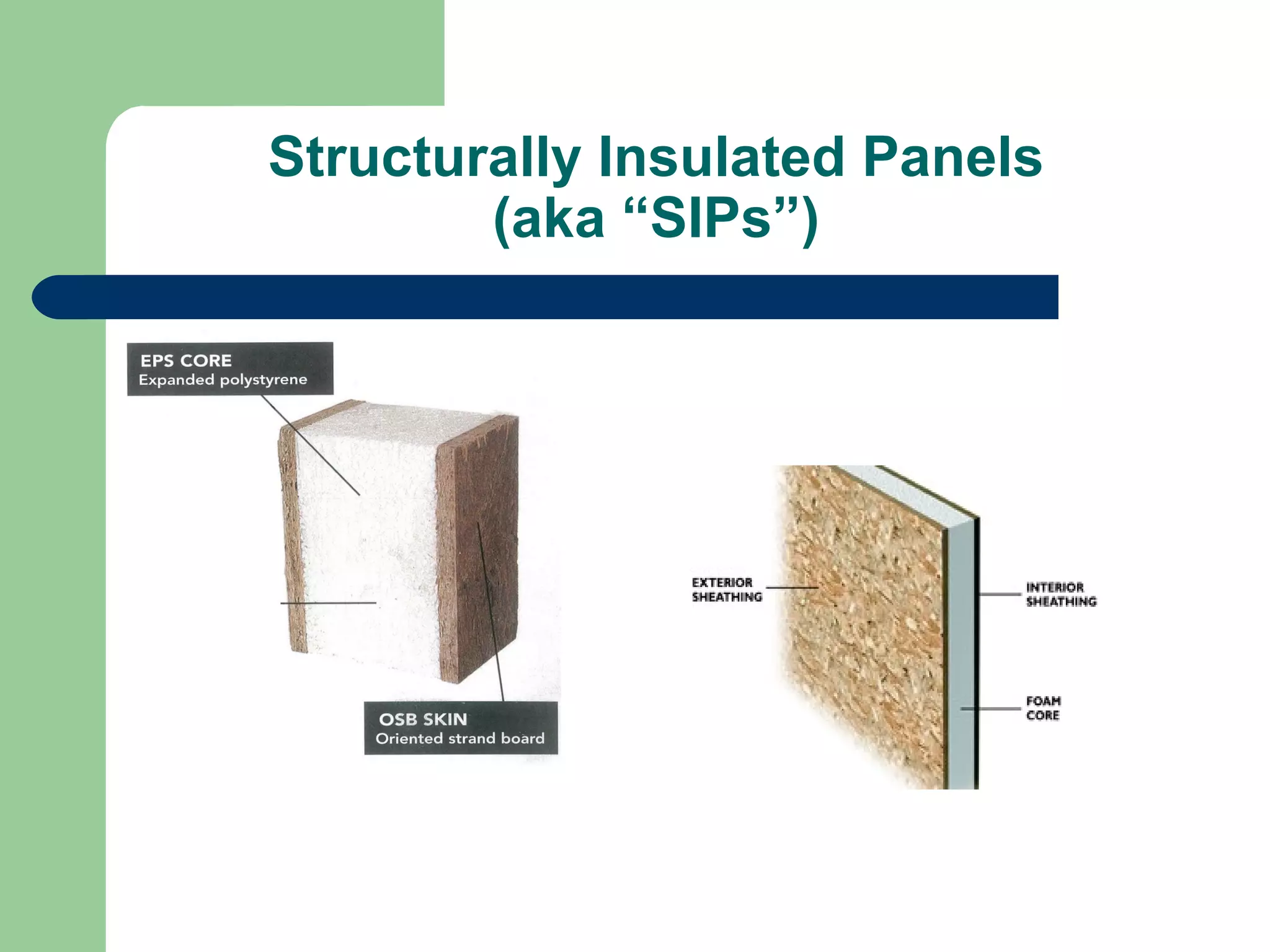

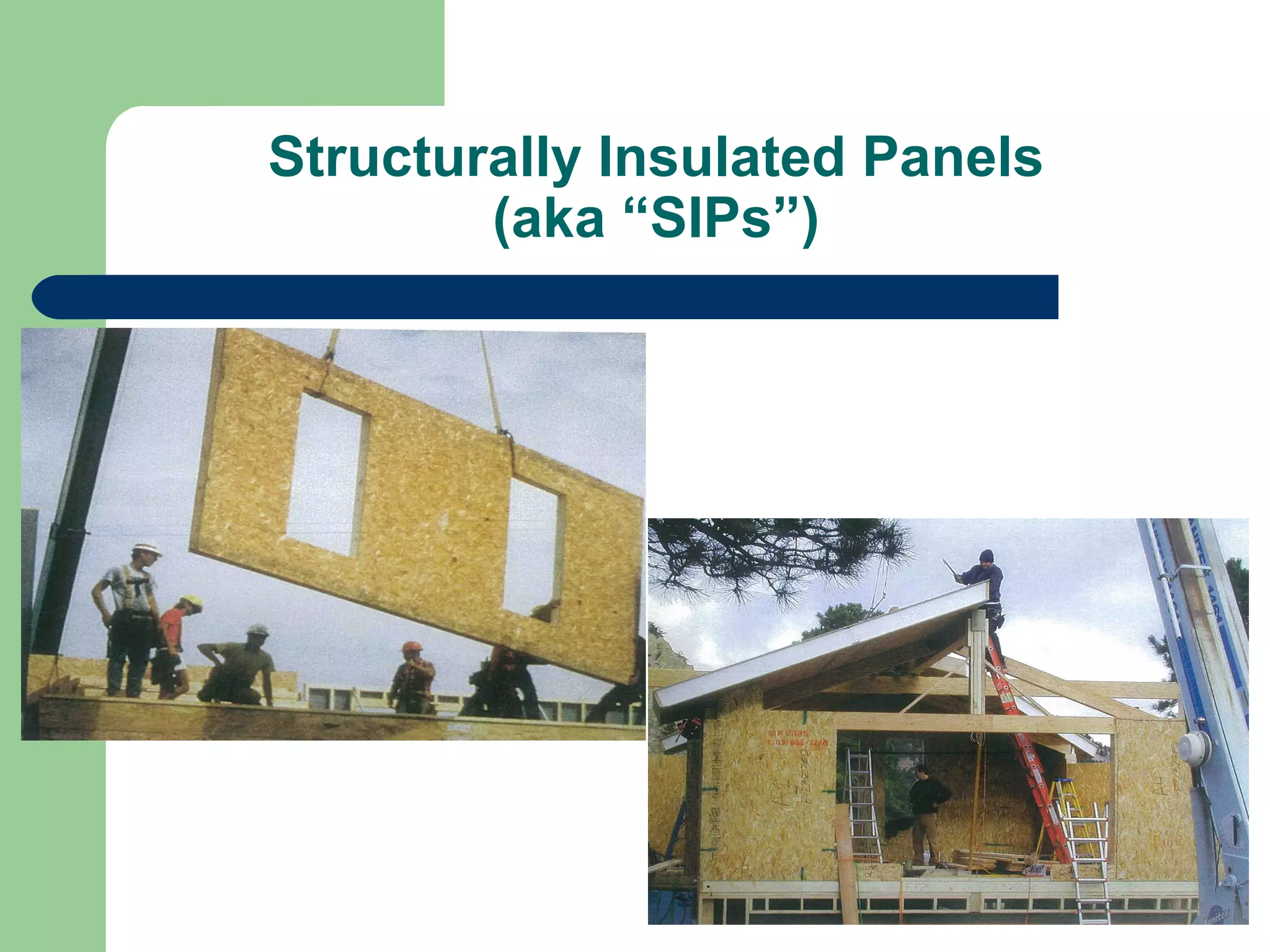

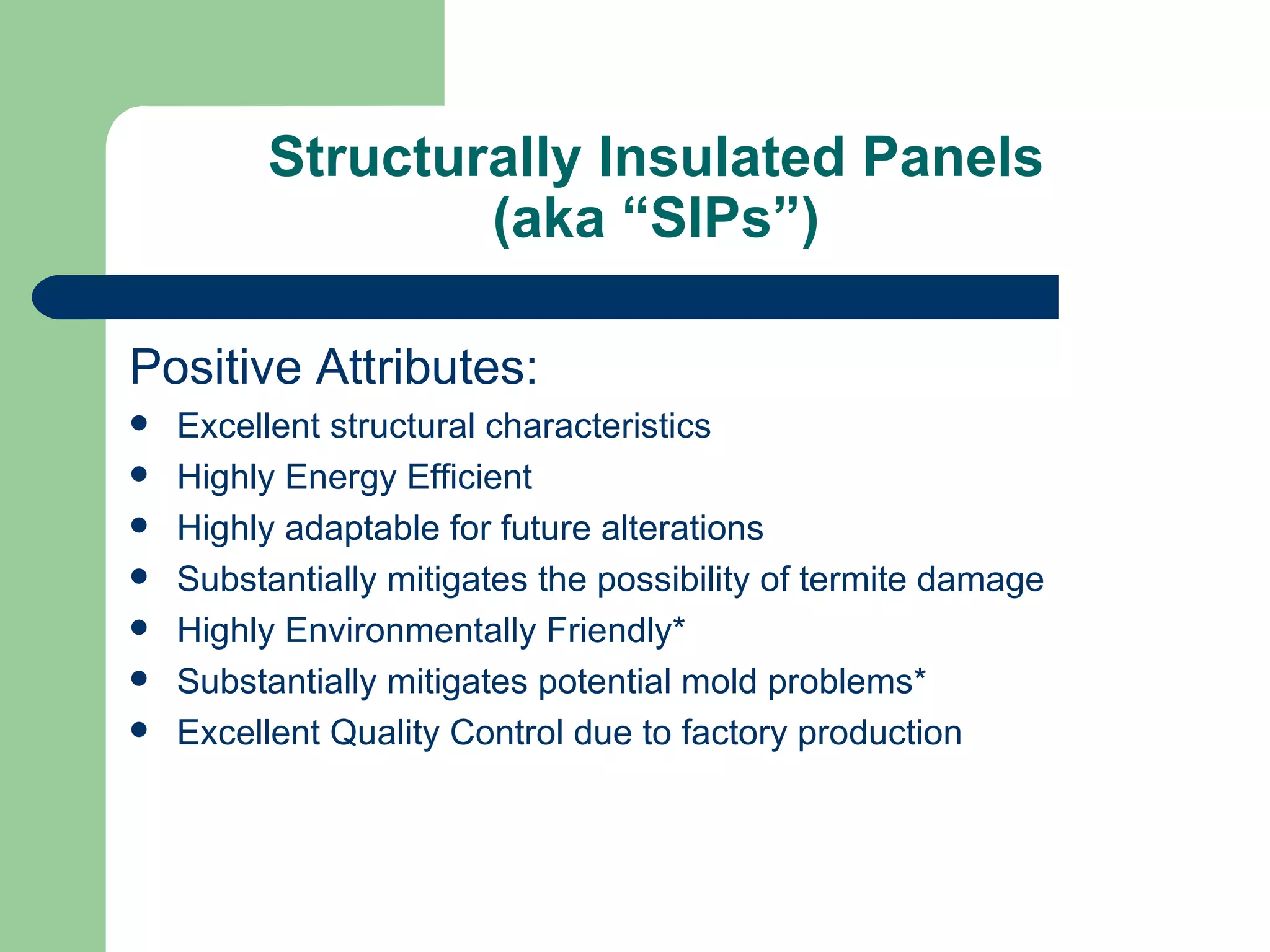

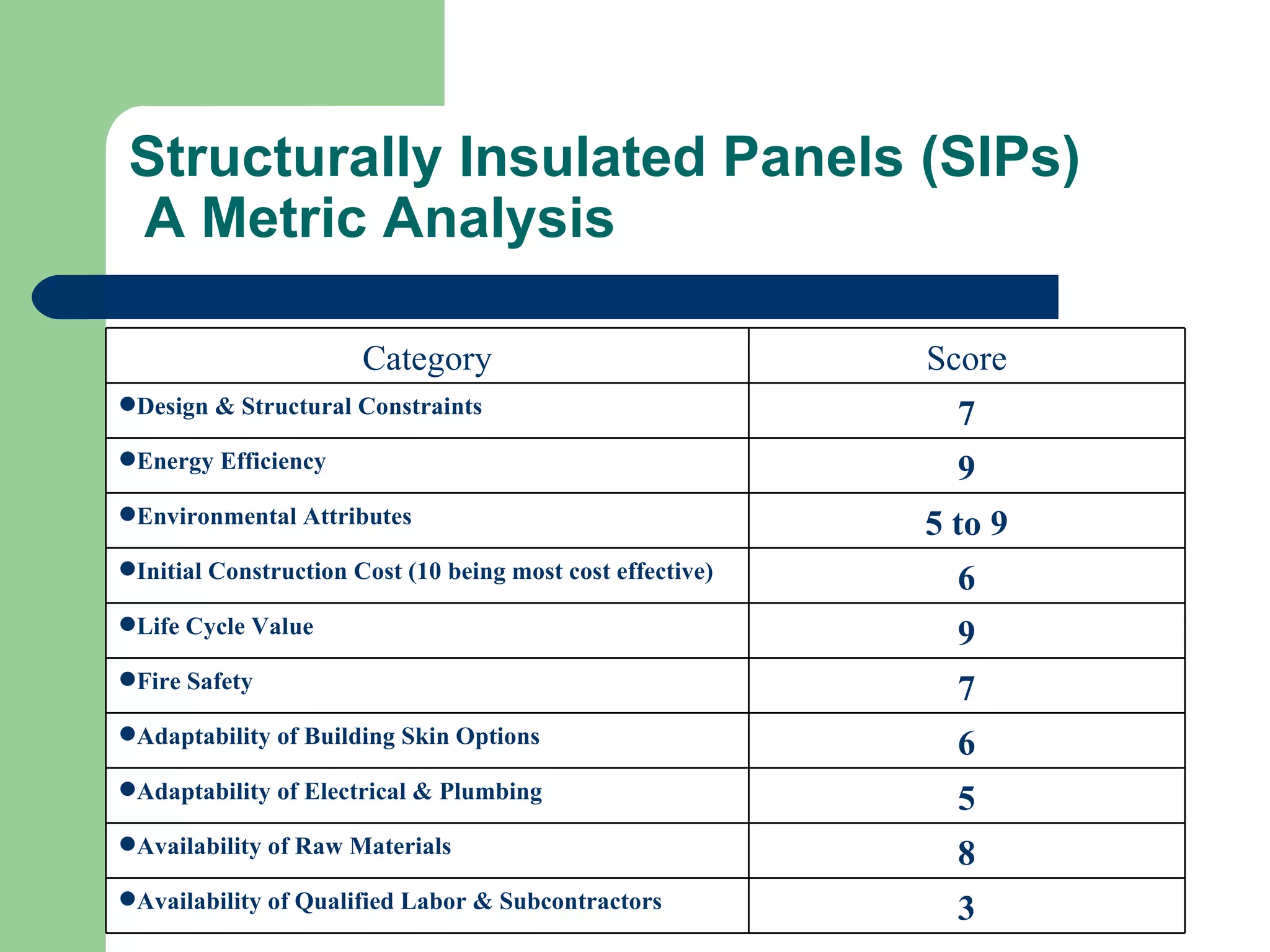

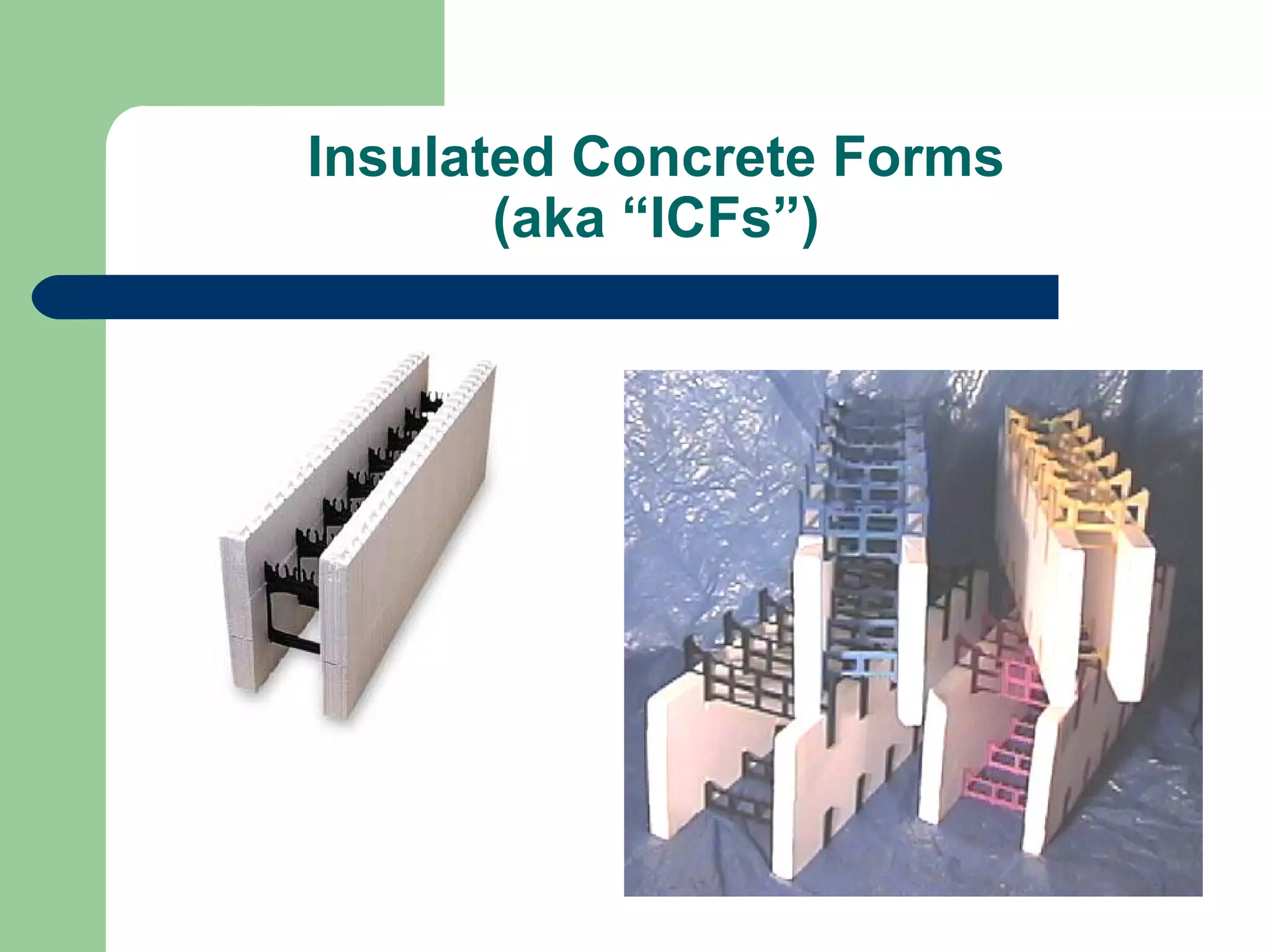

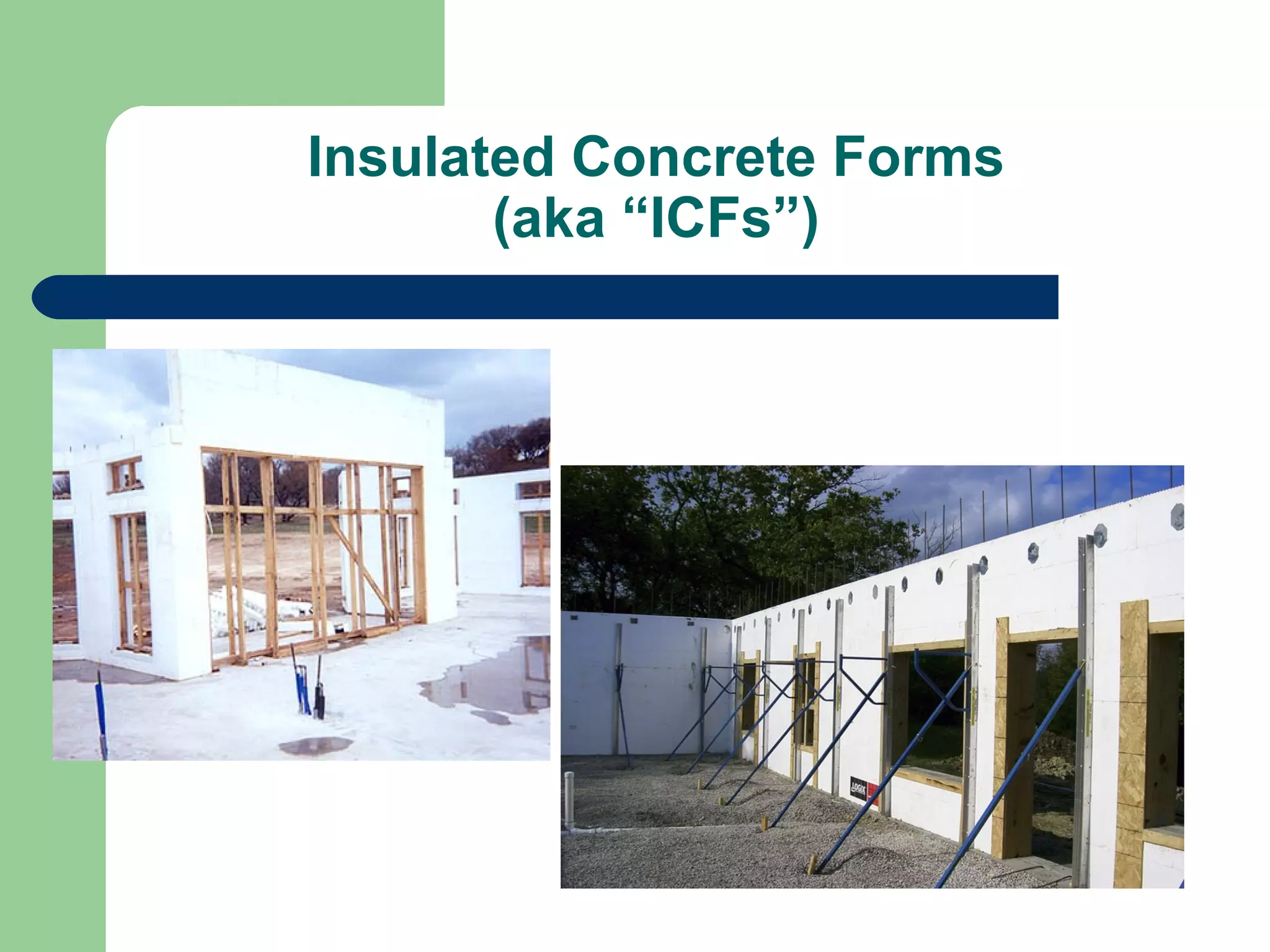

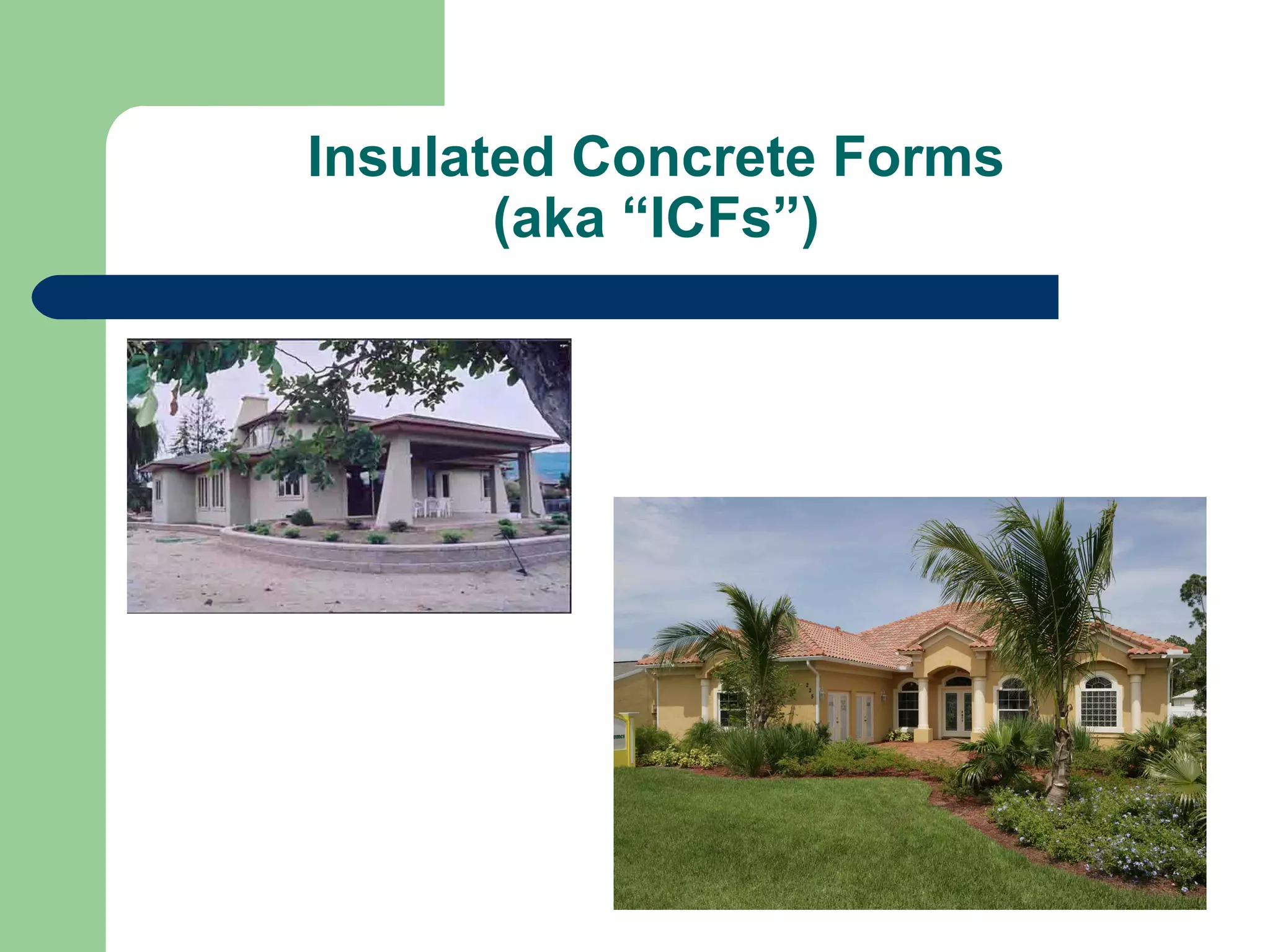

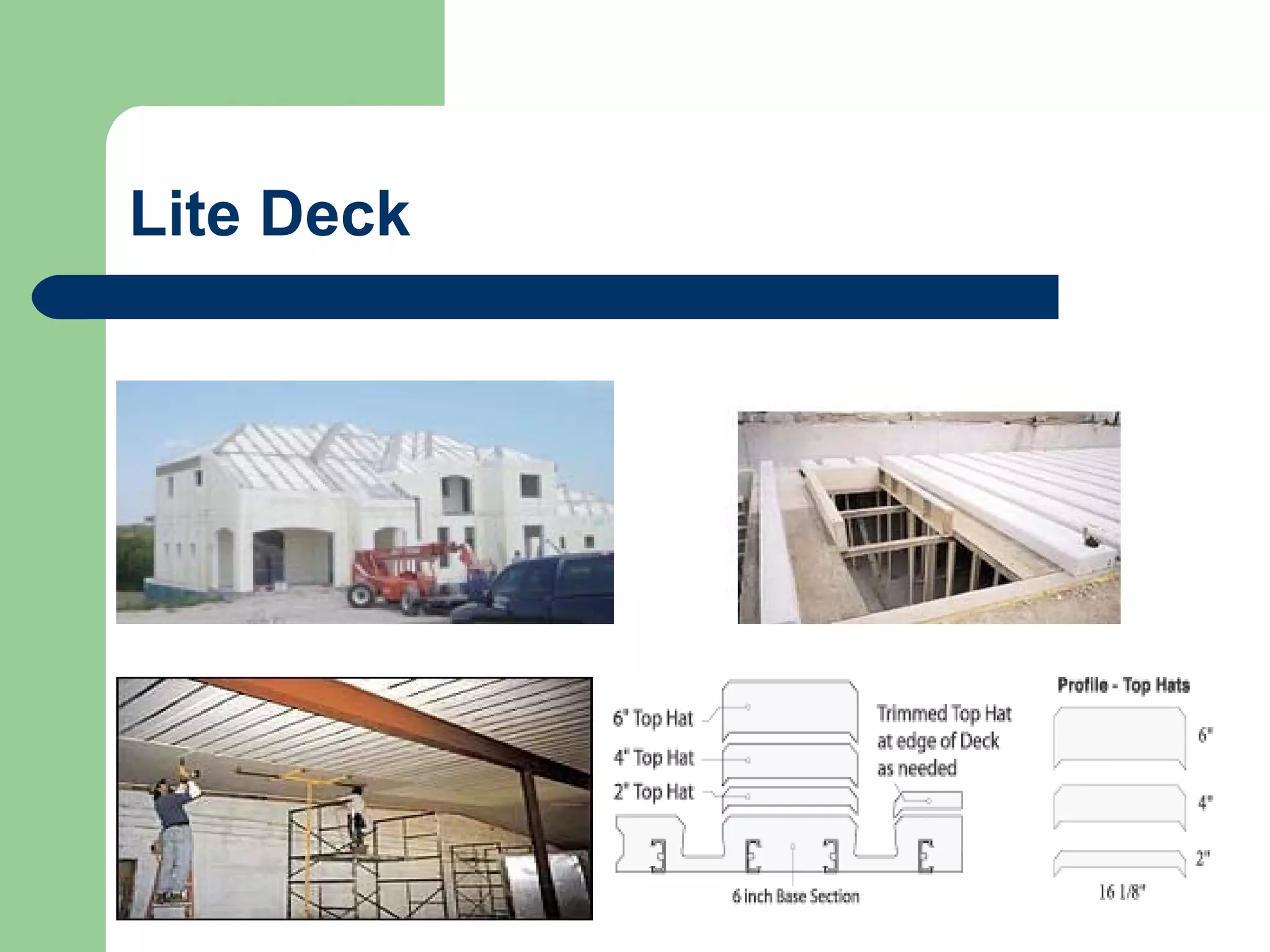

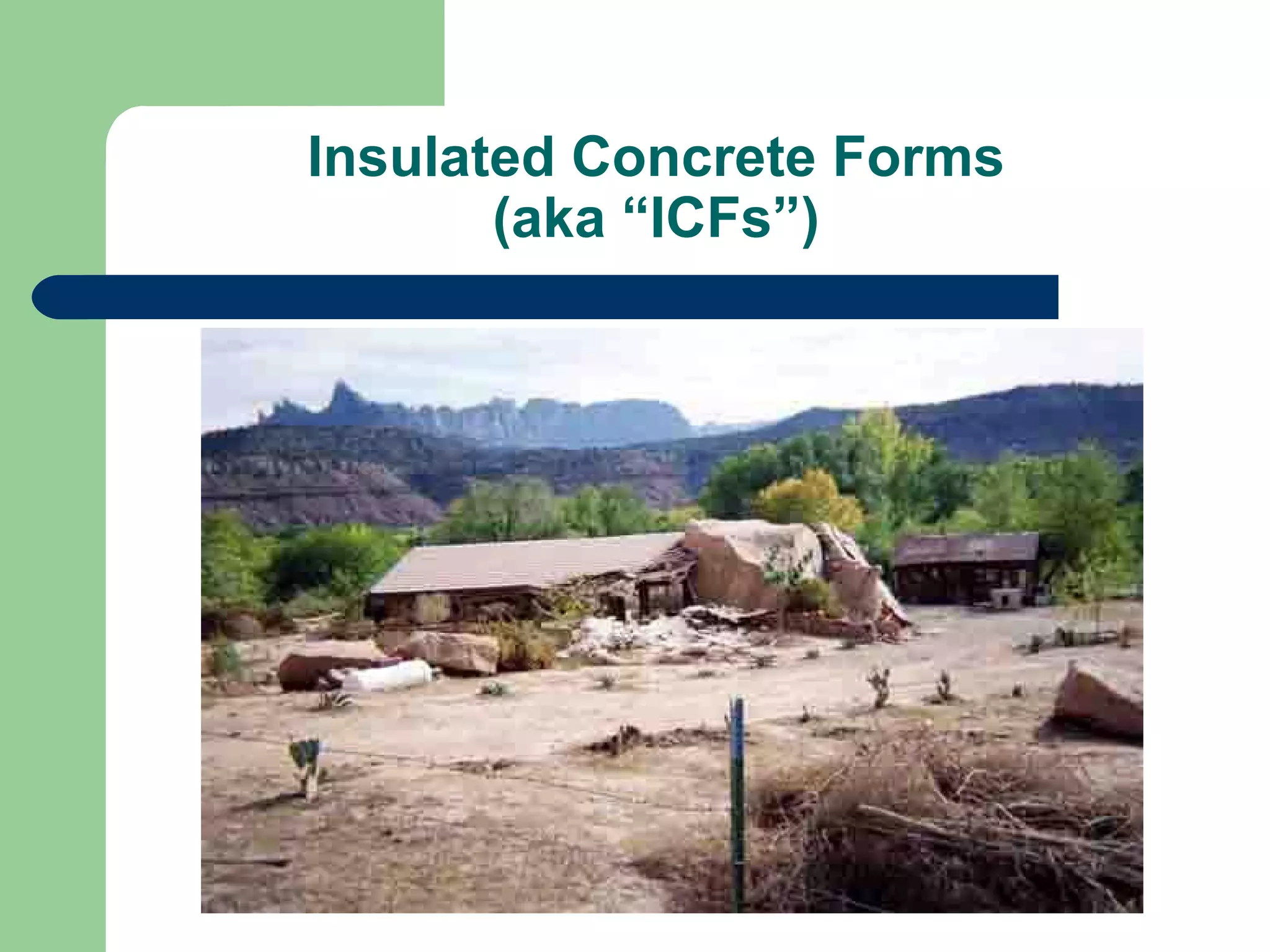

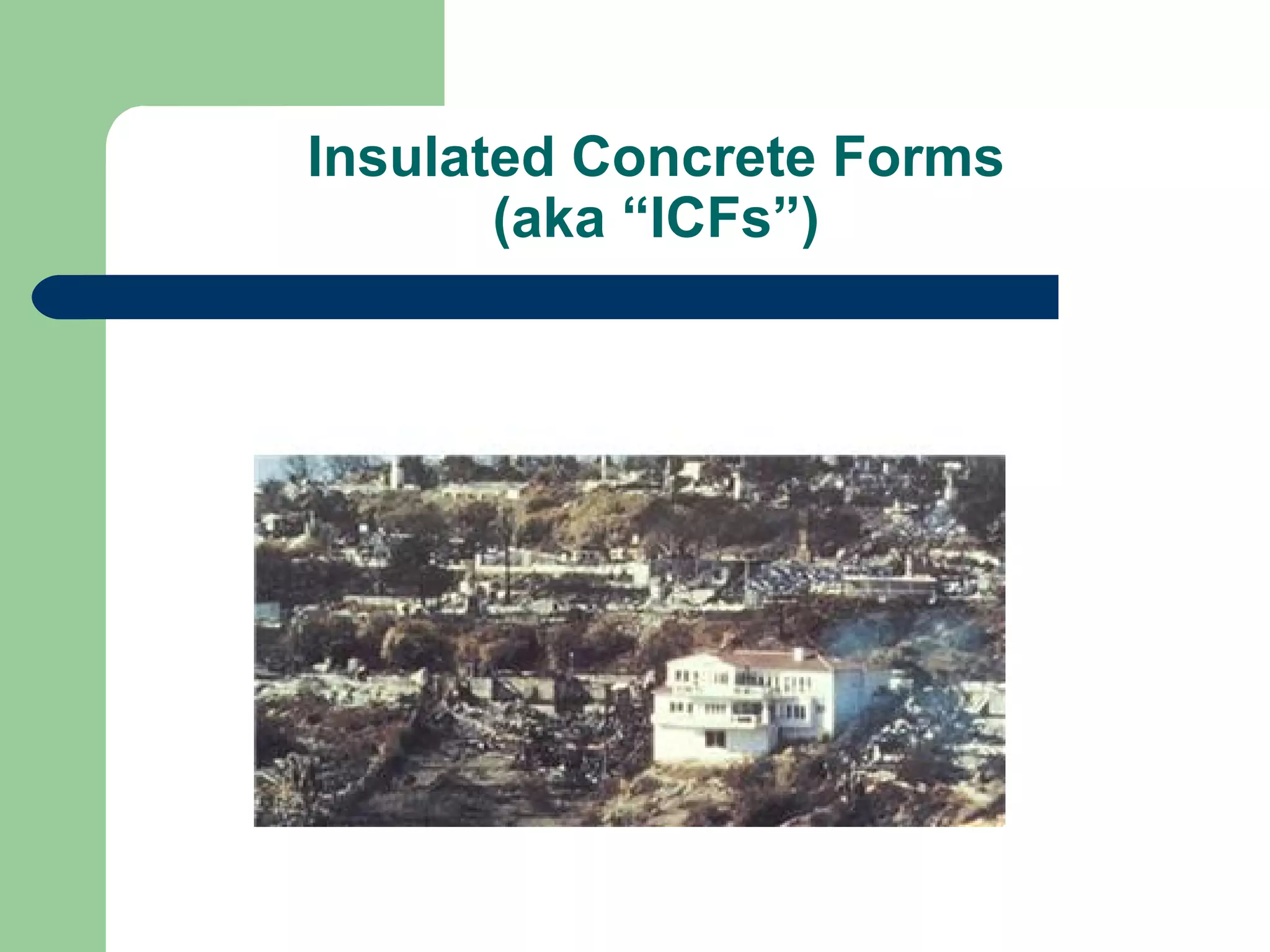

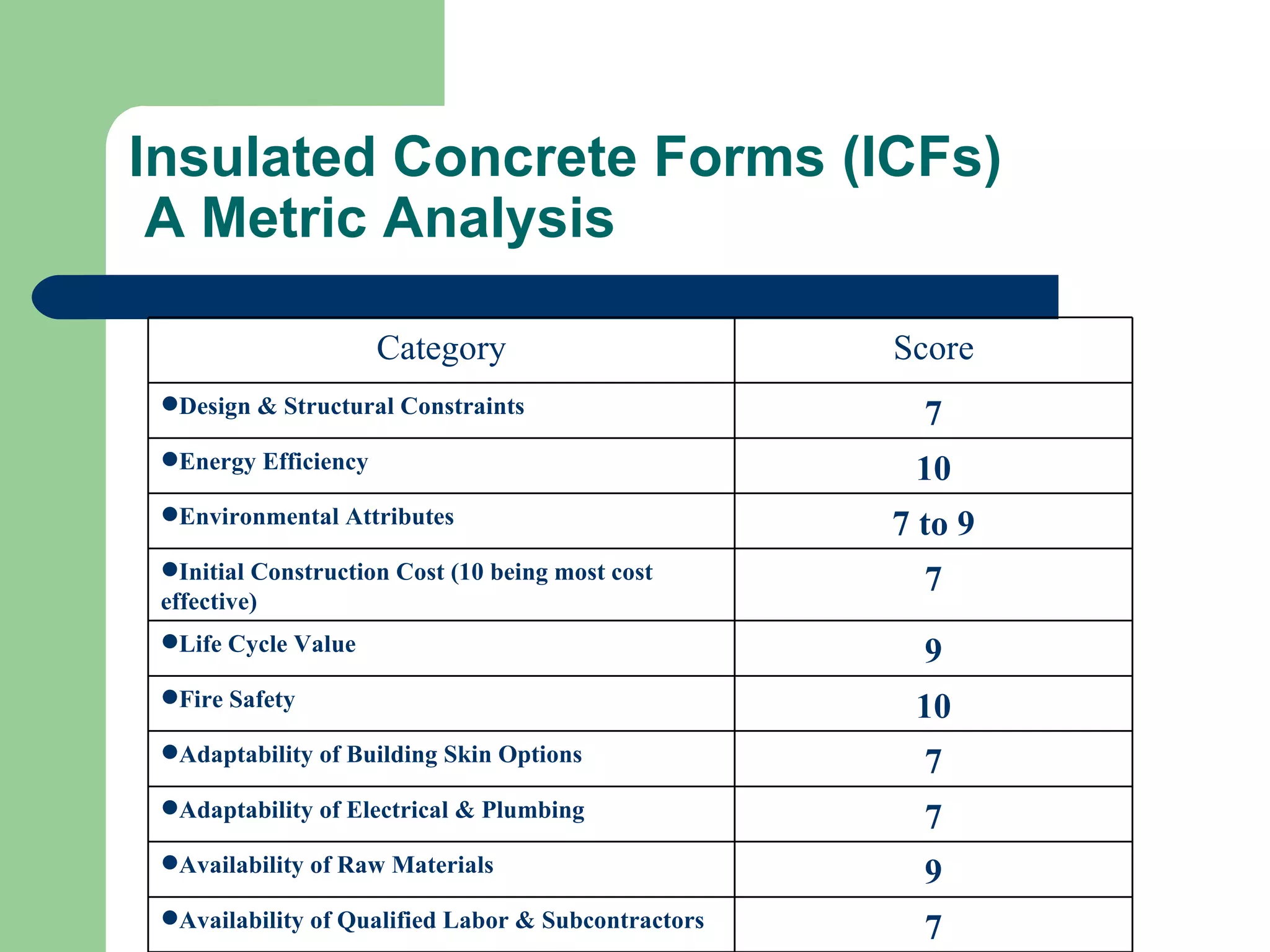

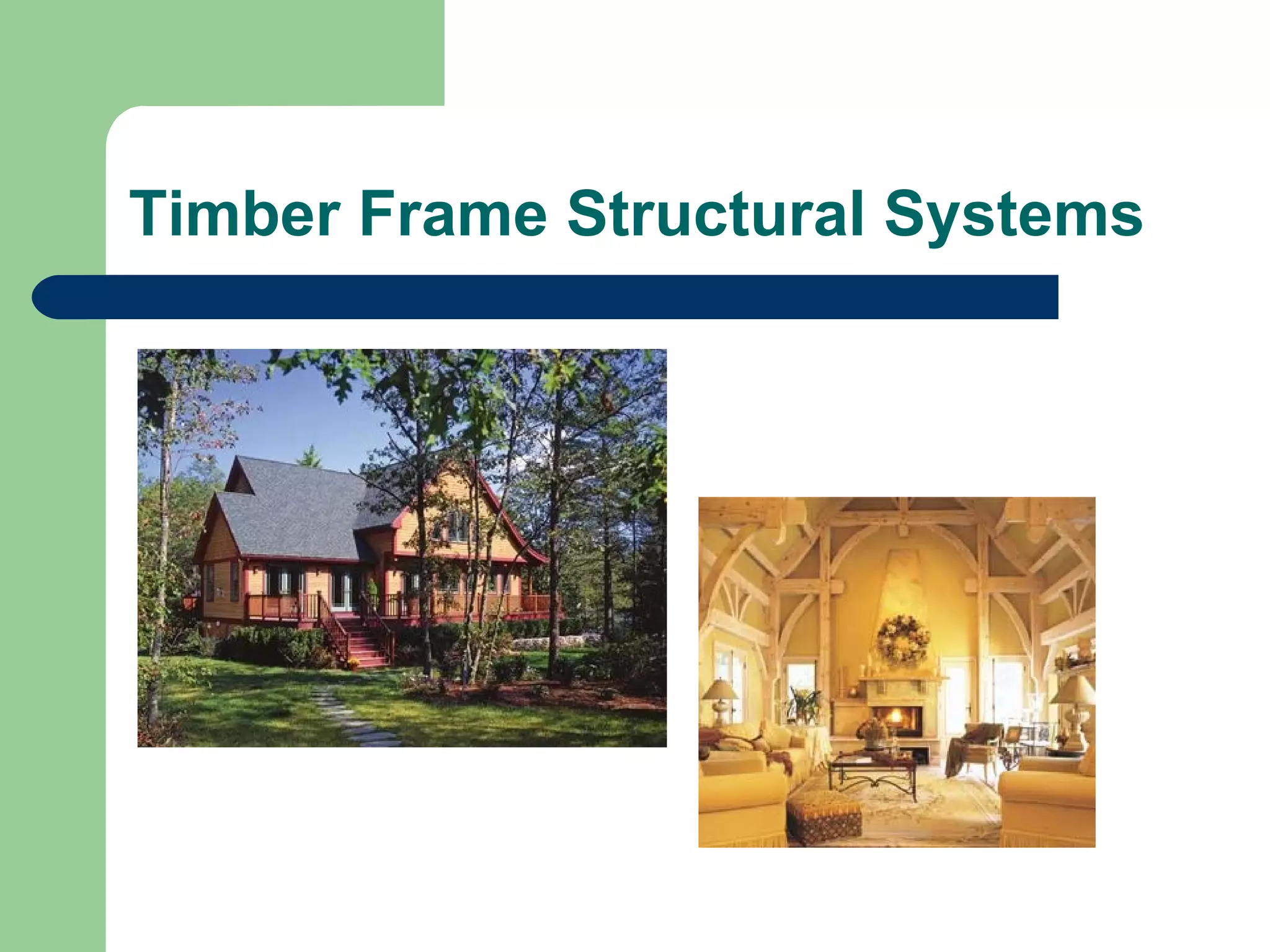

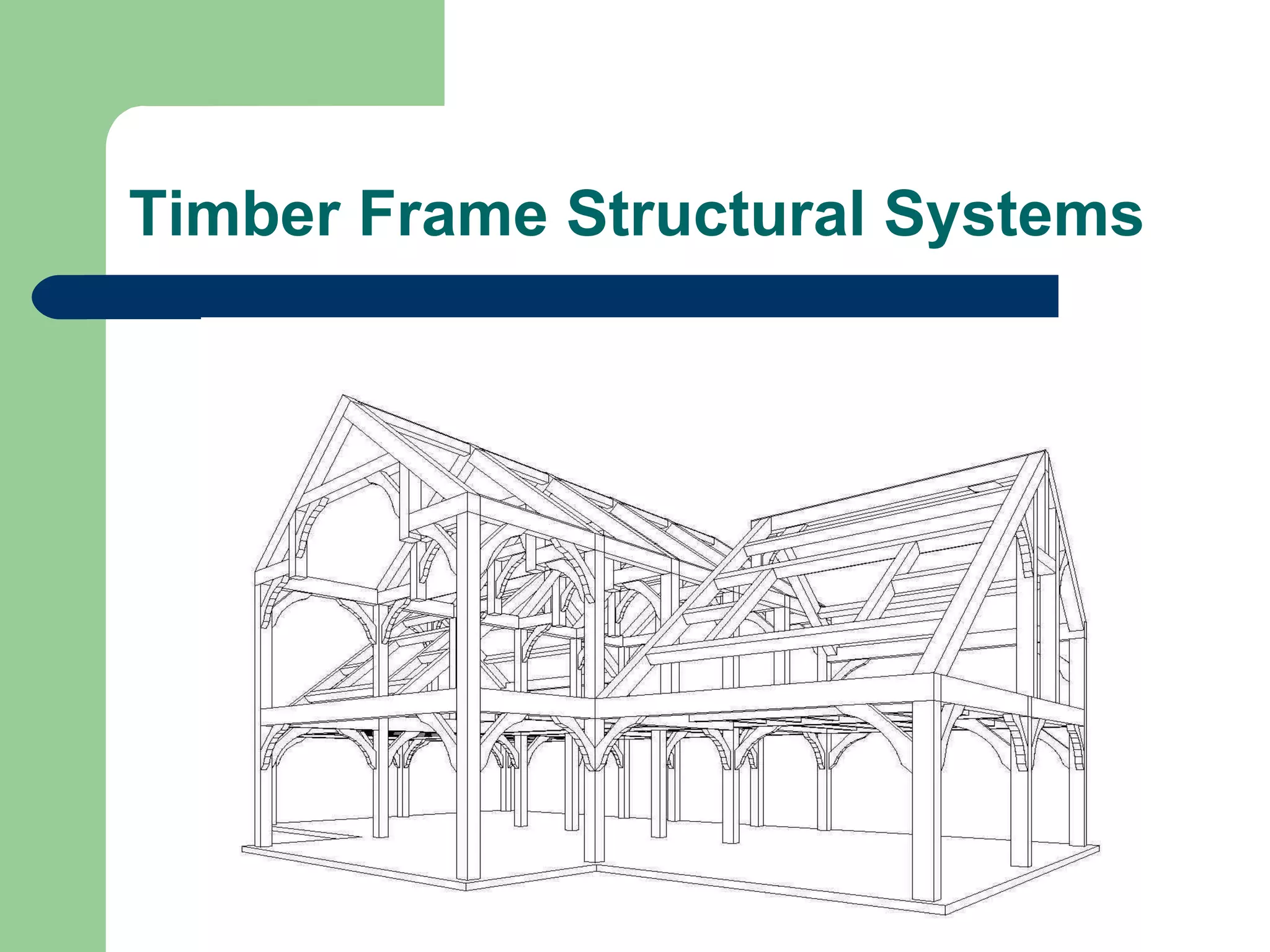

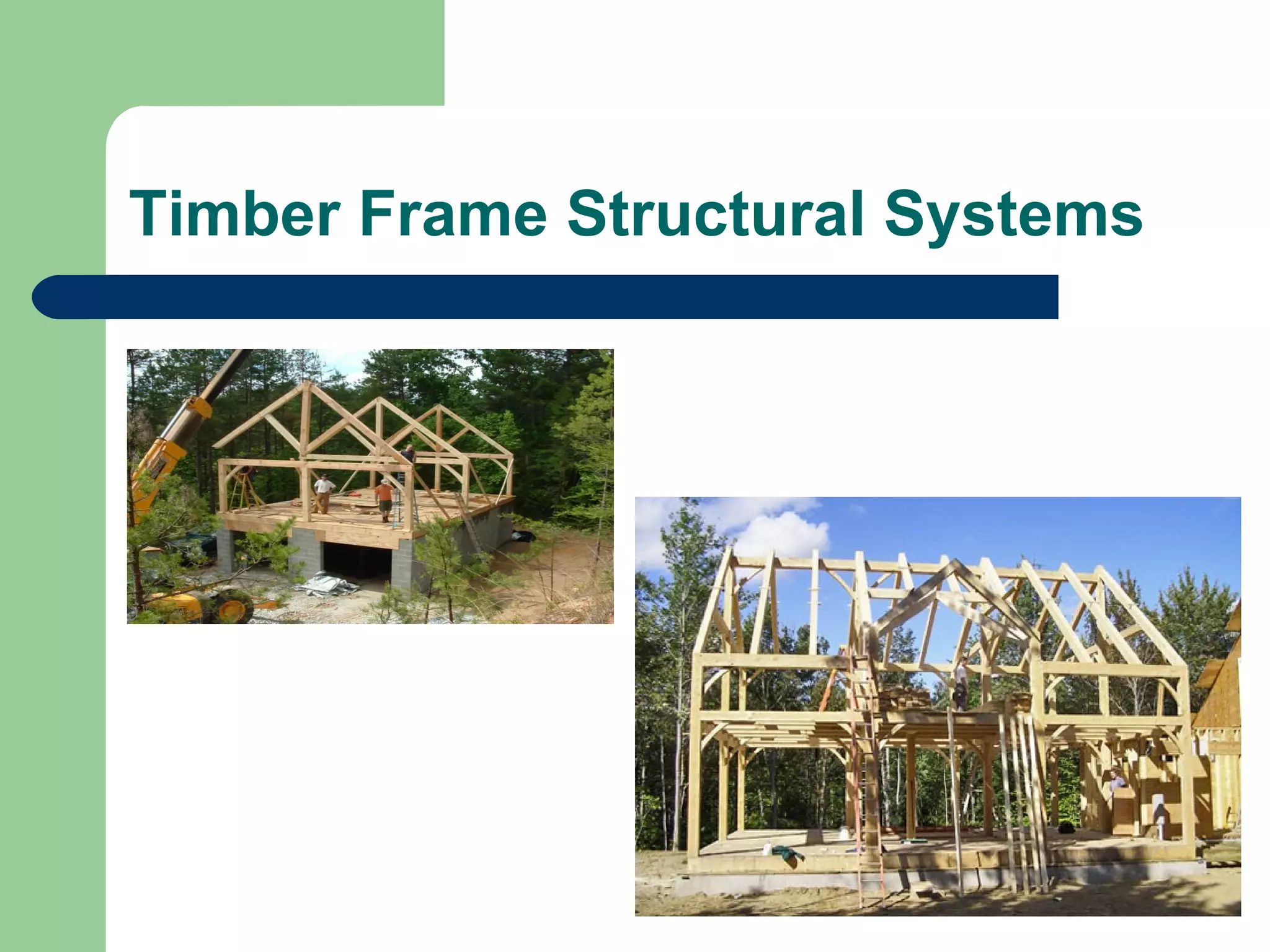

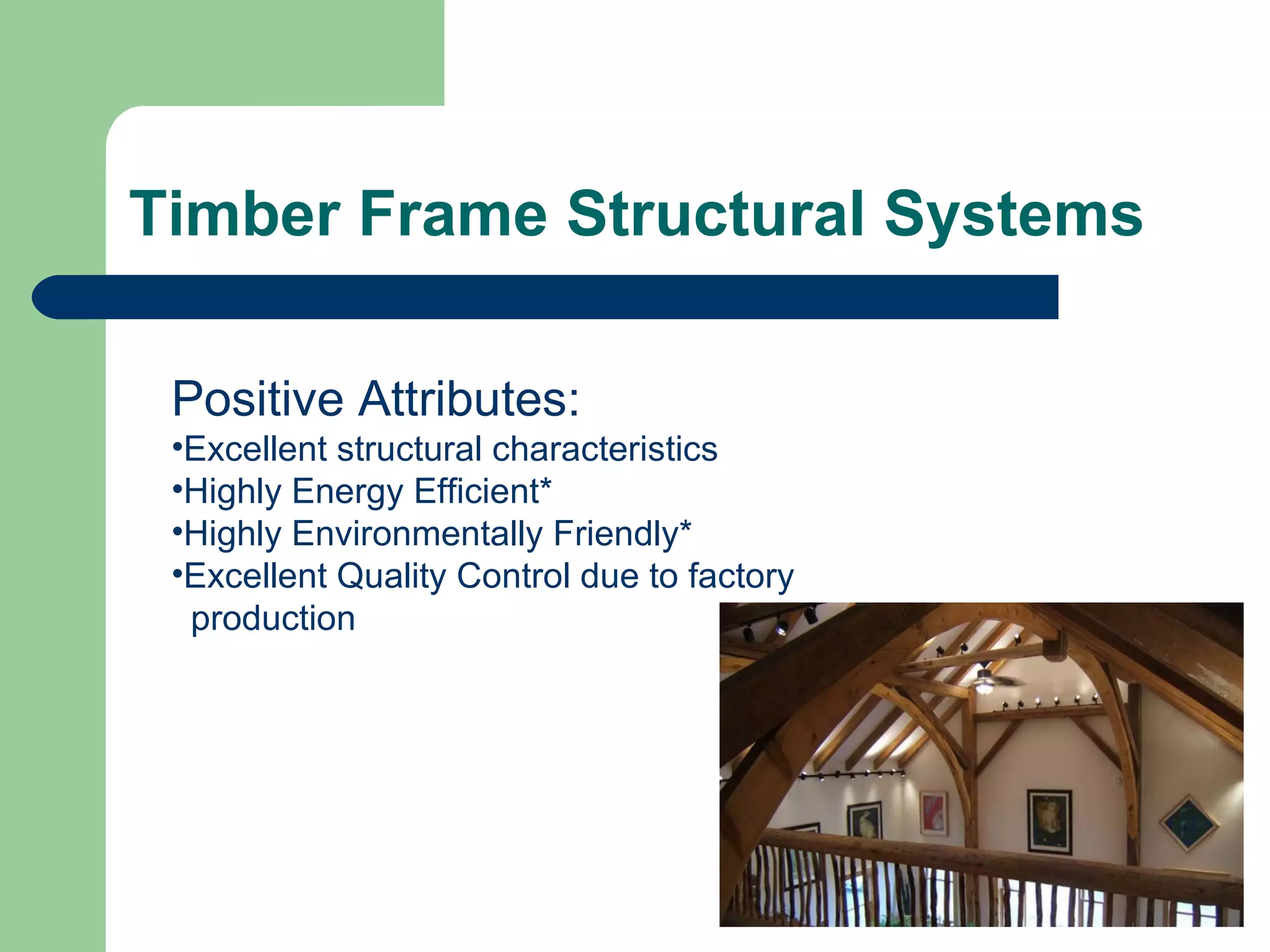

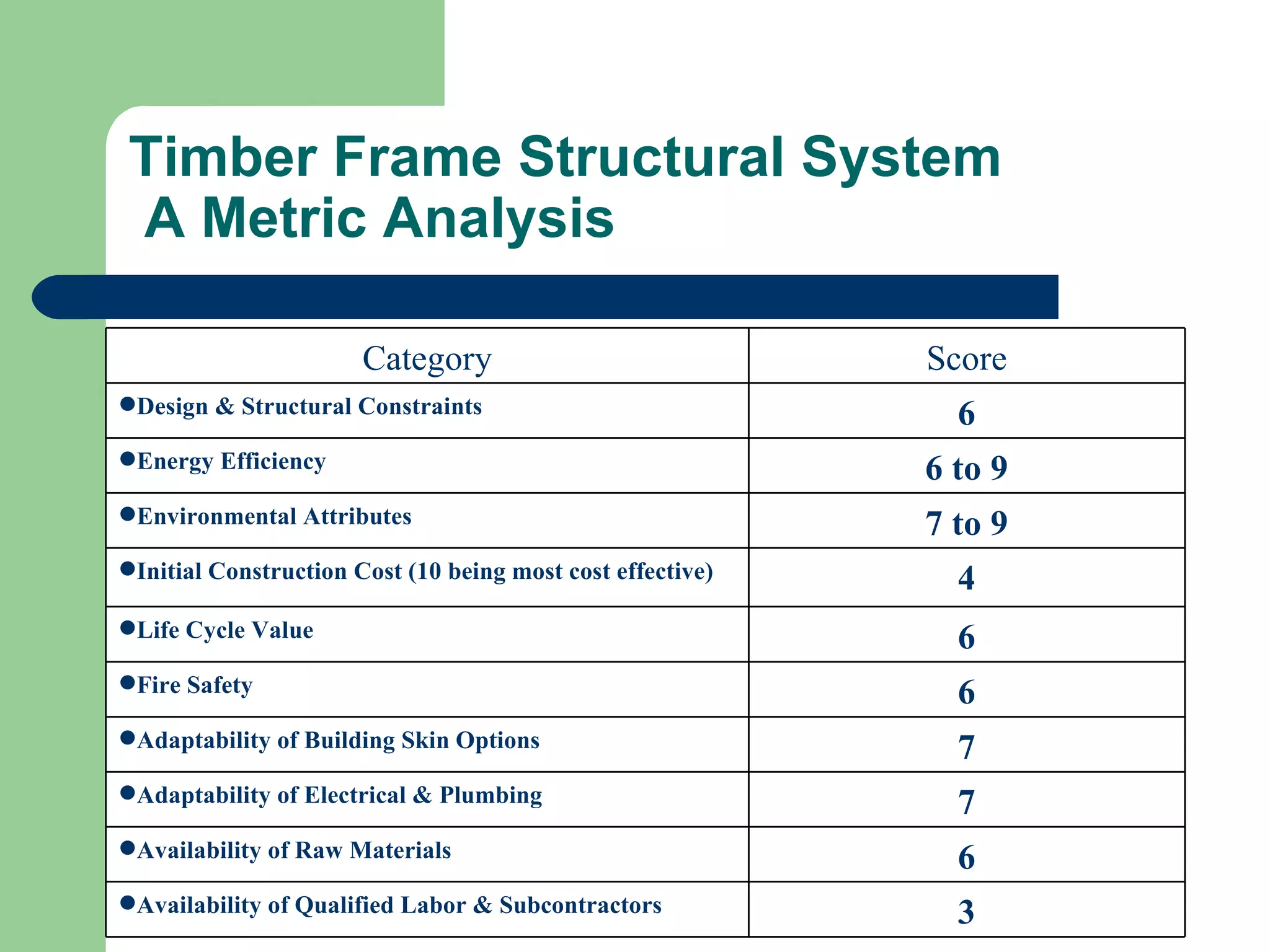

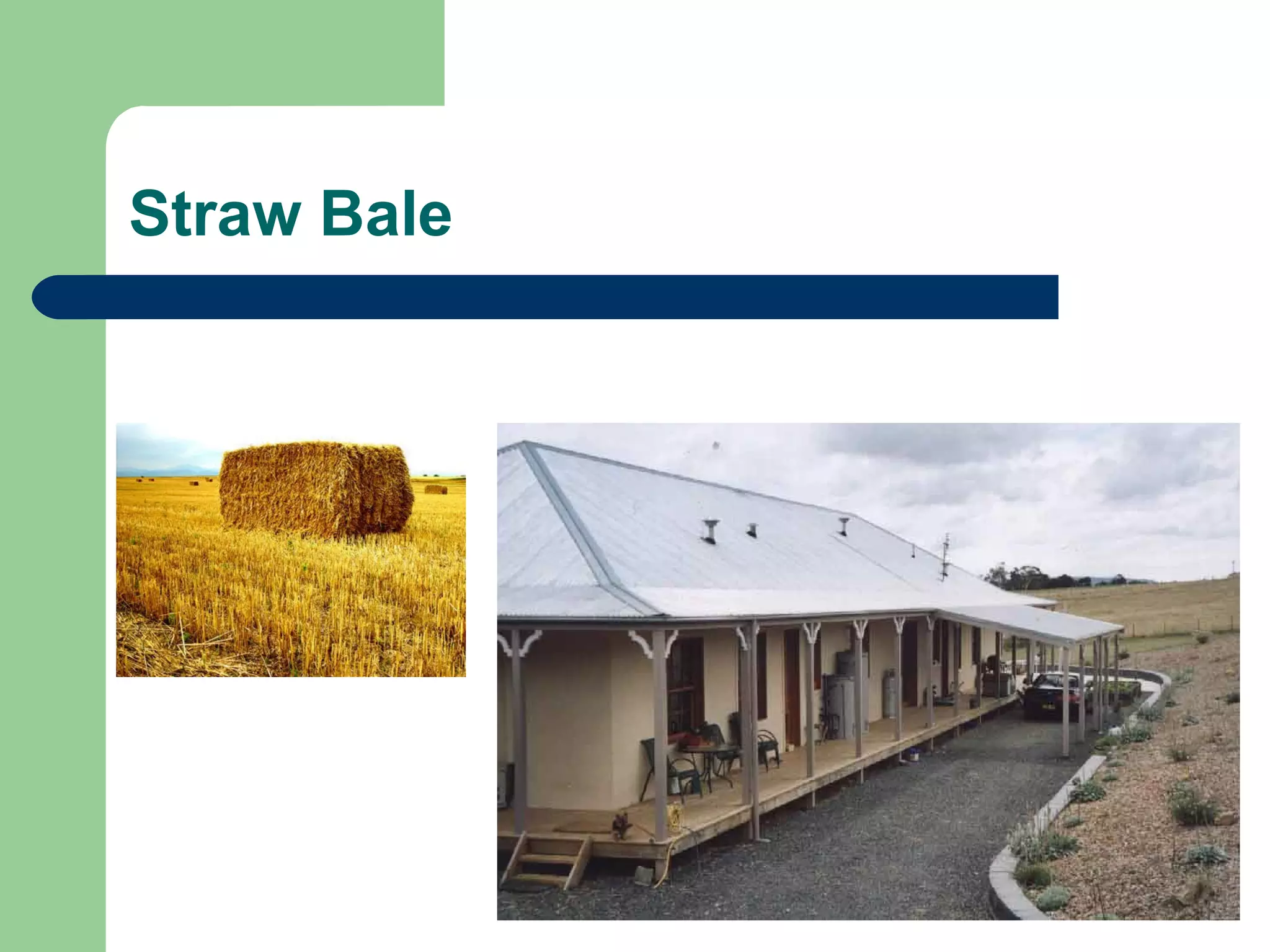

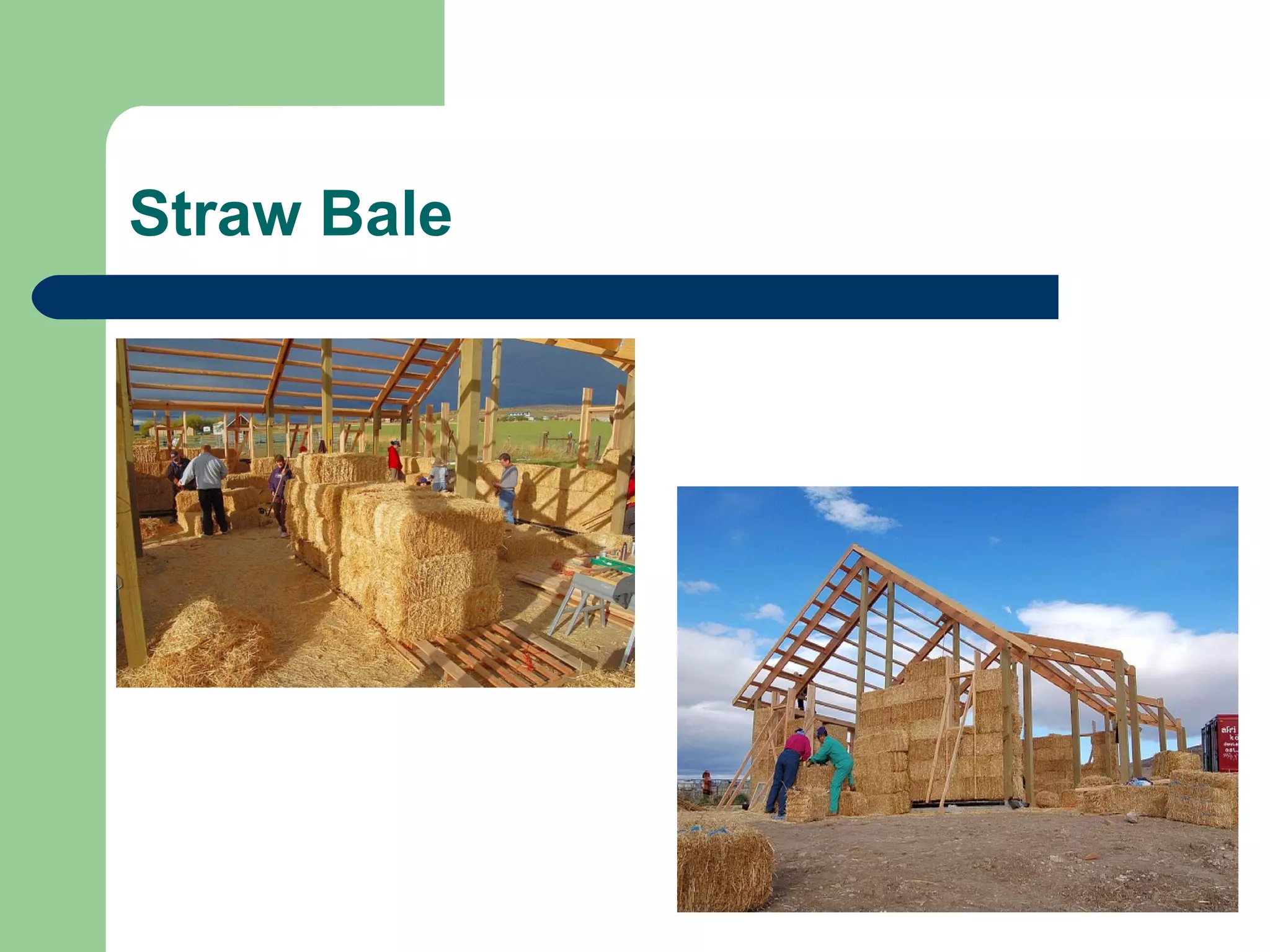

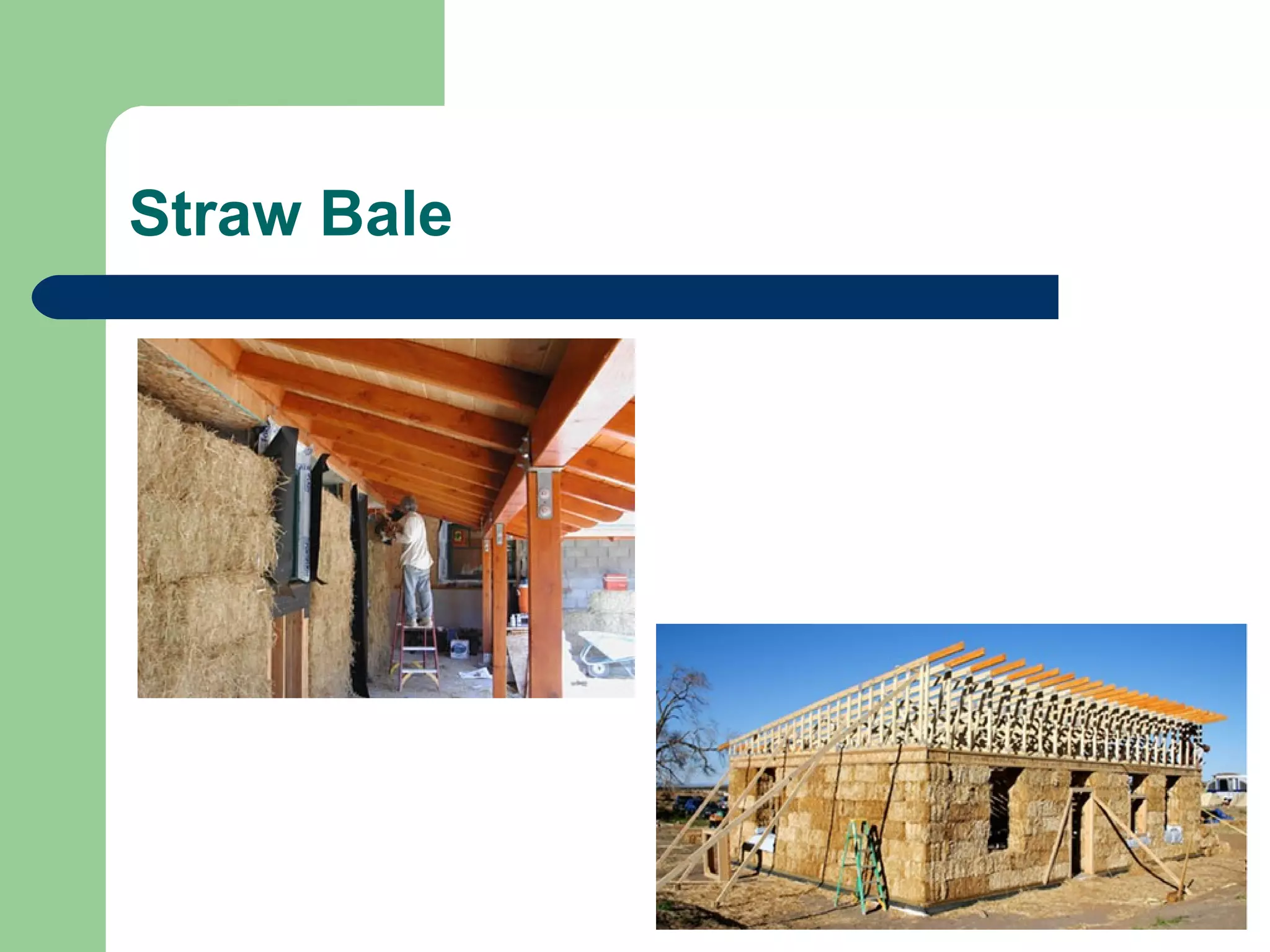

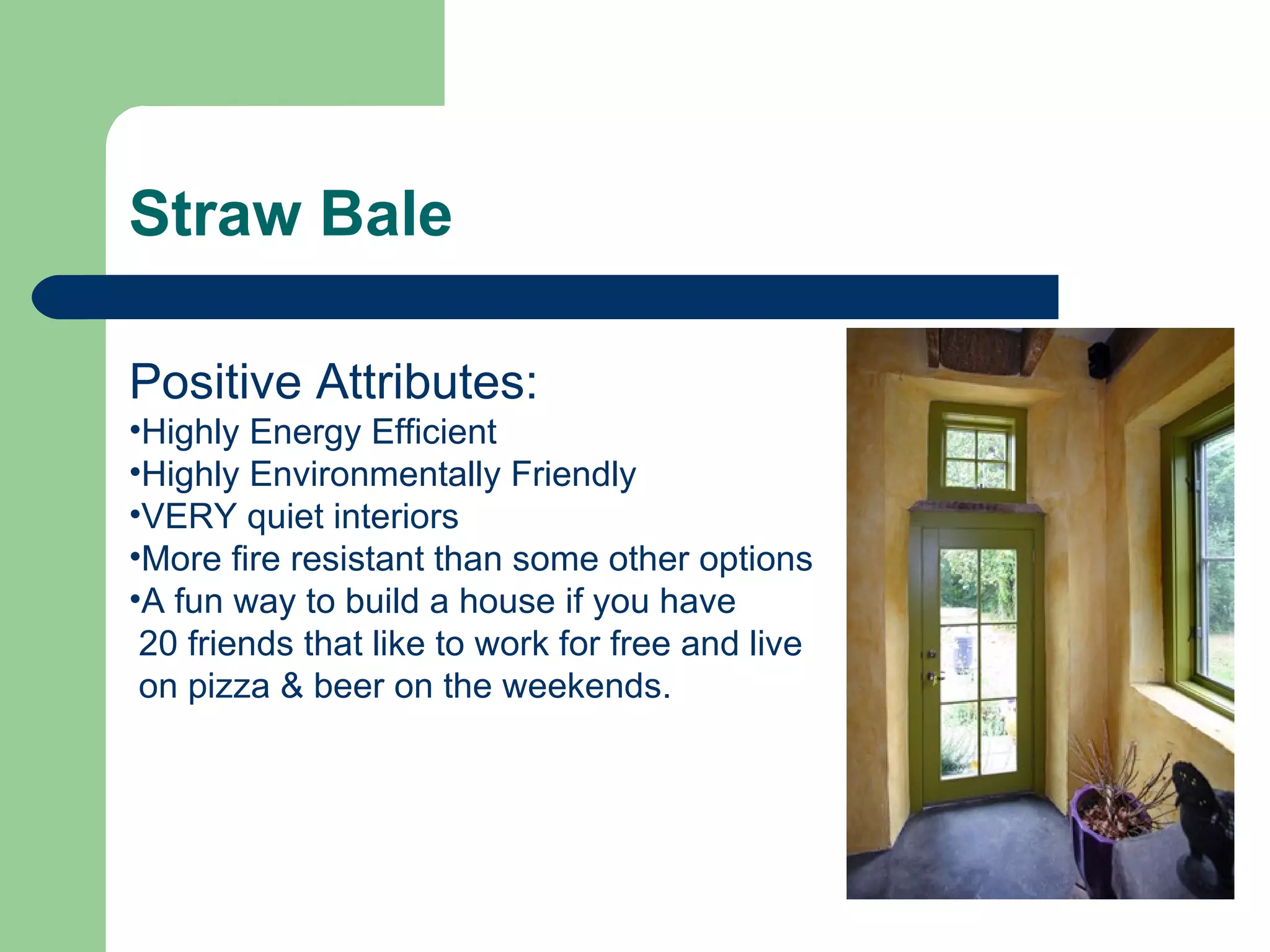

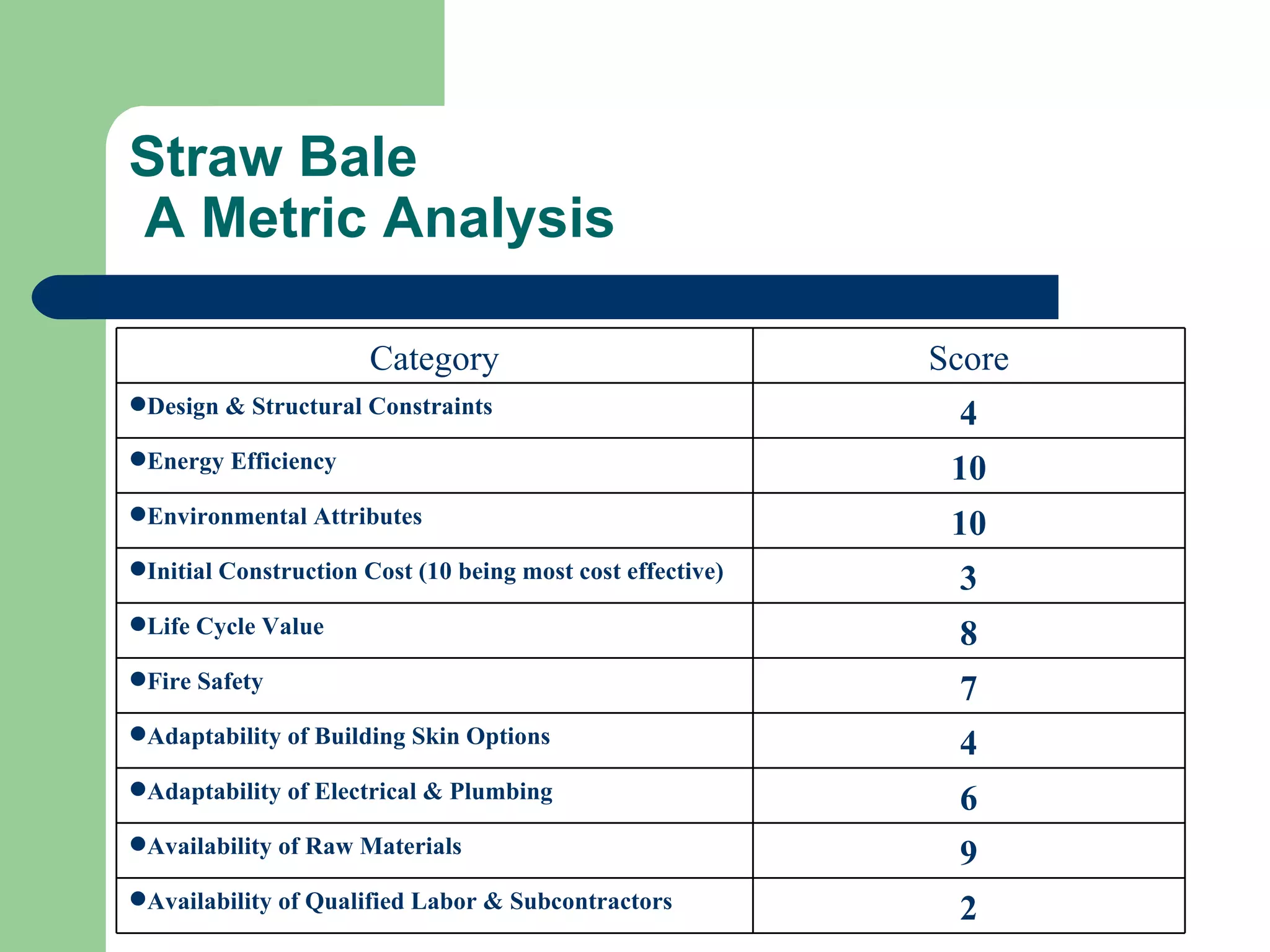

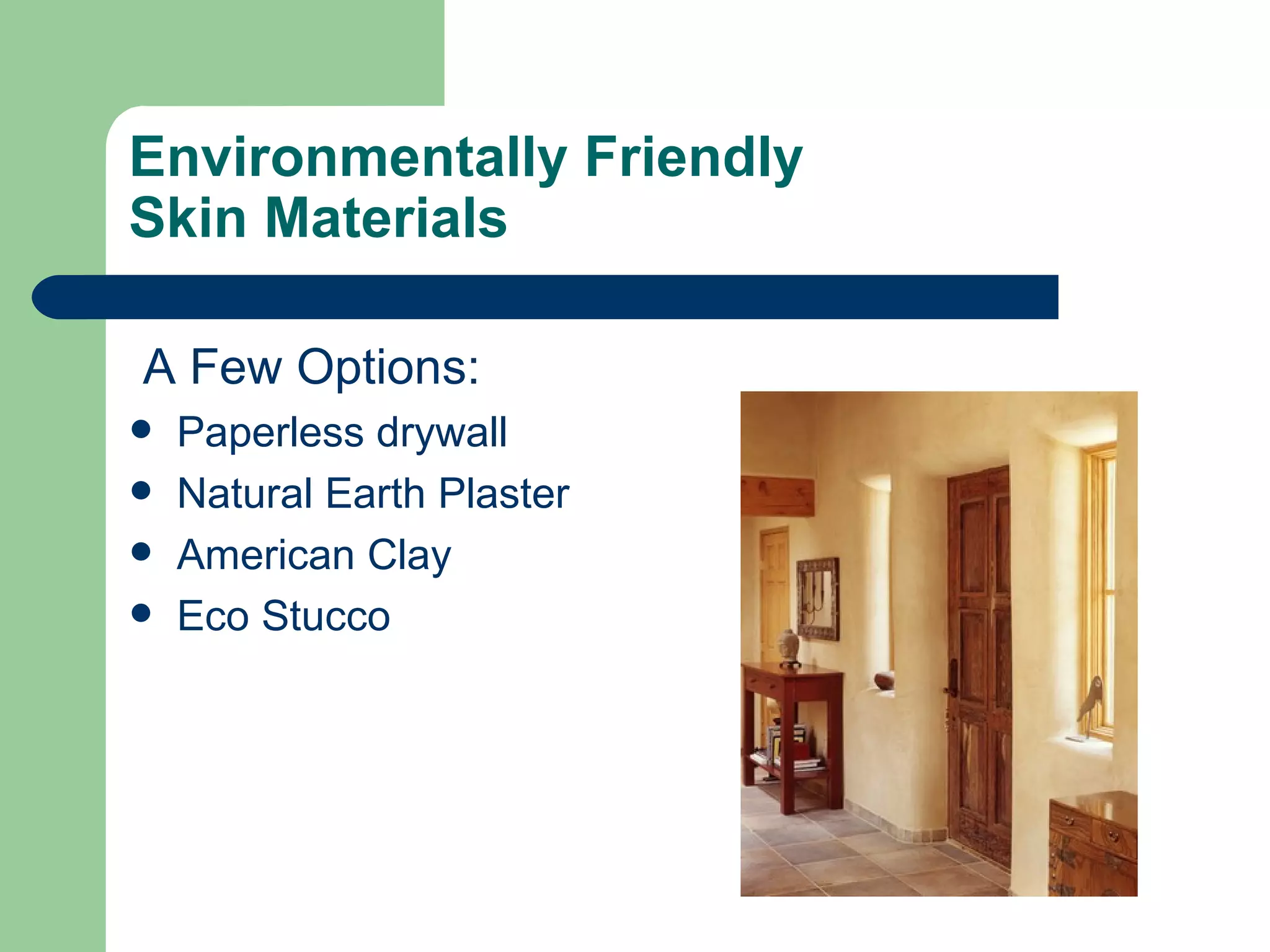

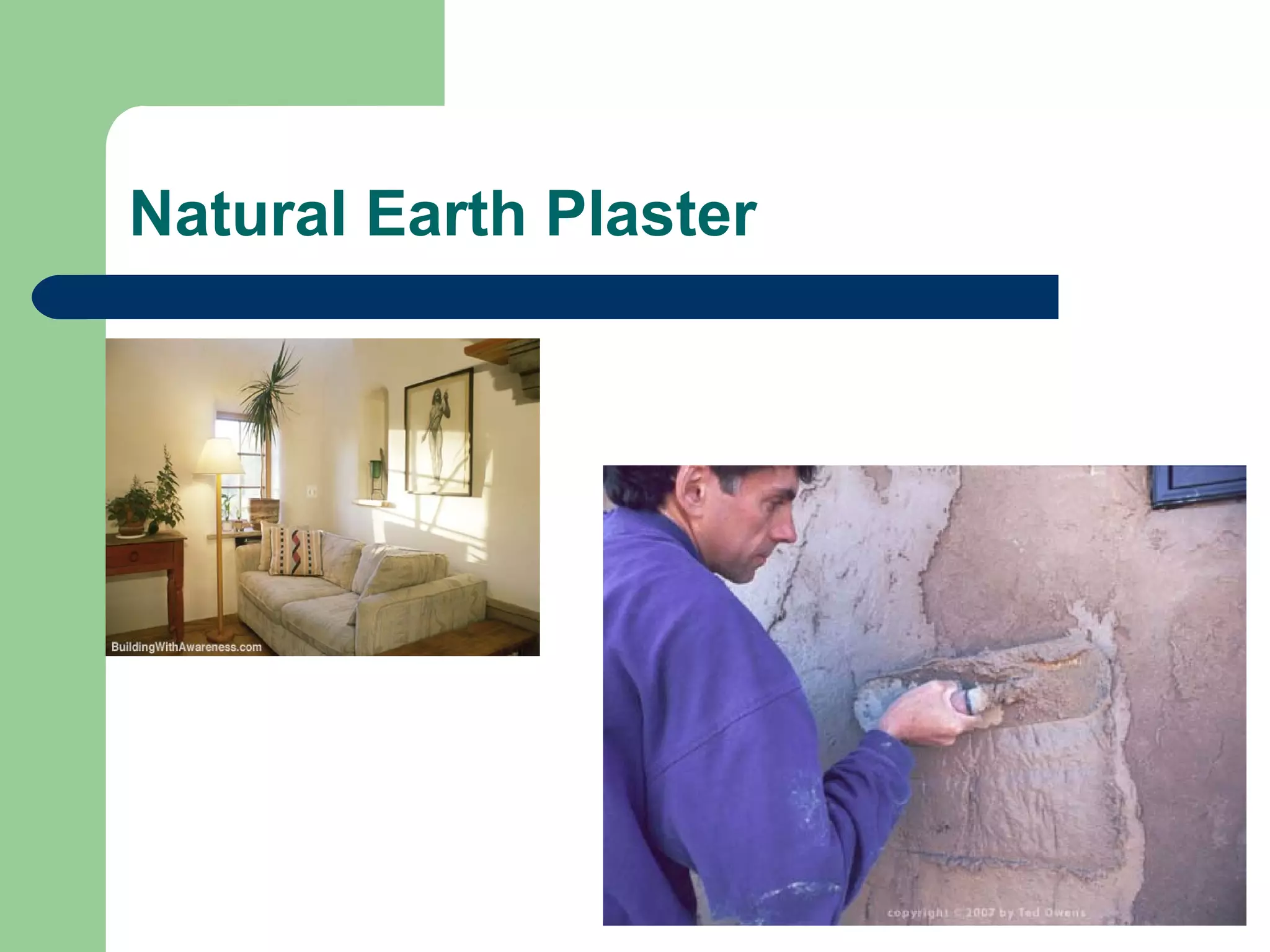

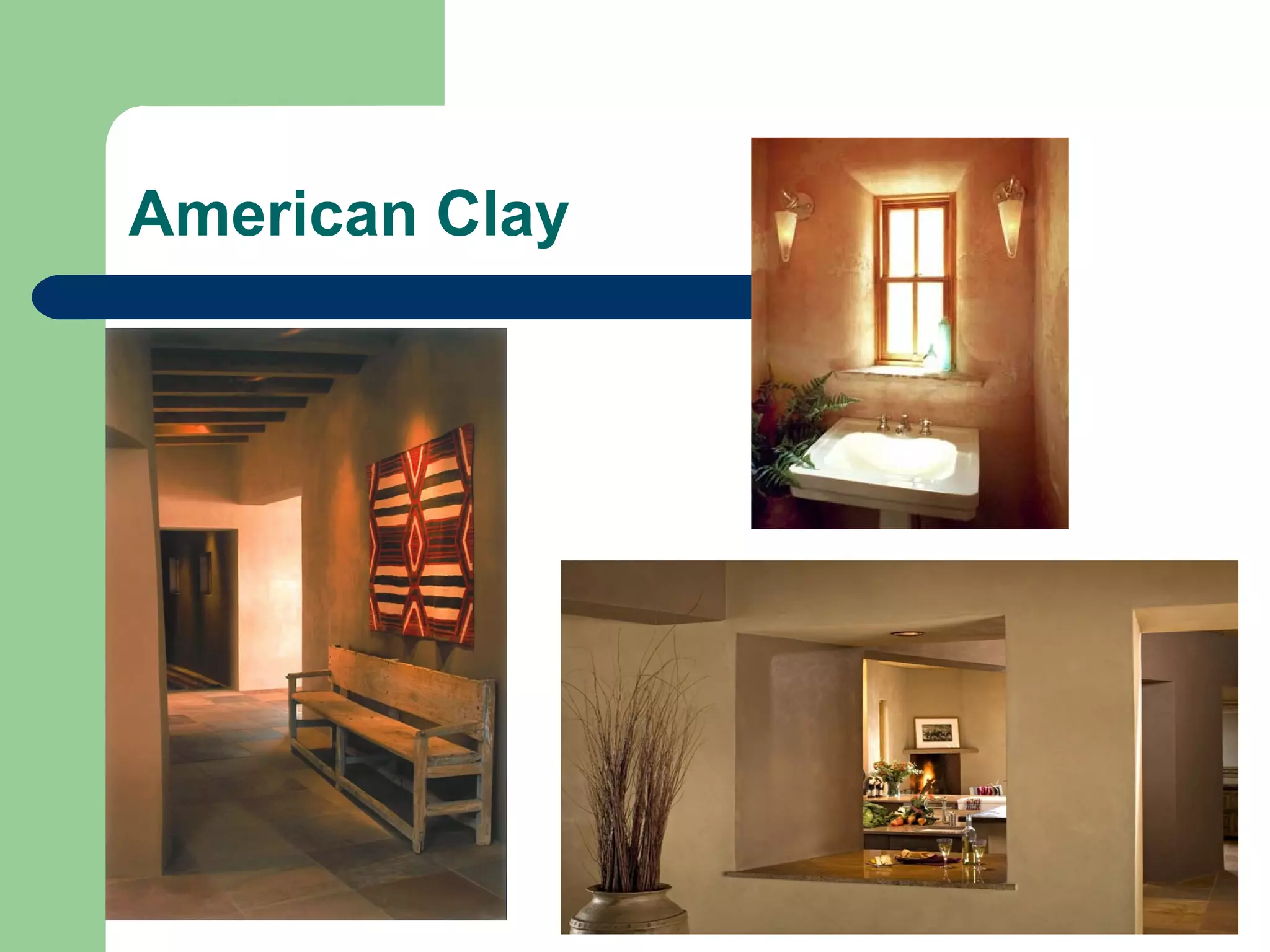

The document discusses various green framing options for building construction, highlighting benefits like cost-effectiveness, energy efficiency, health considerations, and environmental concerns. It compares alternative framing systems such as conventional wood, steel, and insulated panels, outlining their pros and cons in areas like energy efficiency, adaptability, and life cycle value. The presentation emphasizes the importance of thoughtful choice in building materials to enhance sustainability and efficiency in construction.