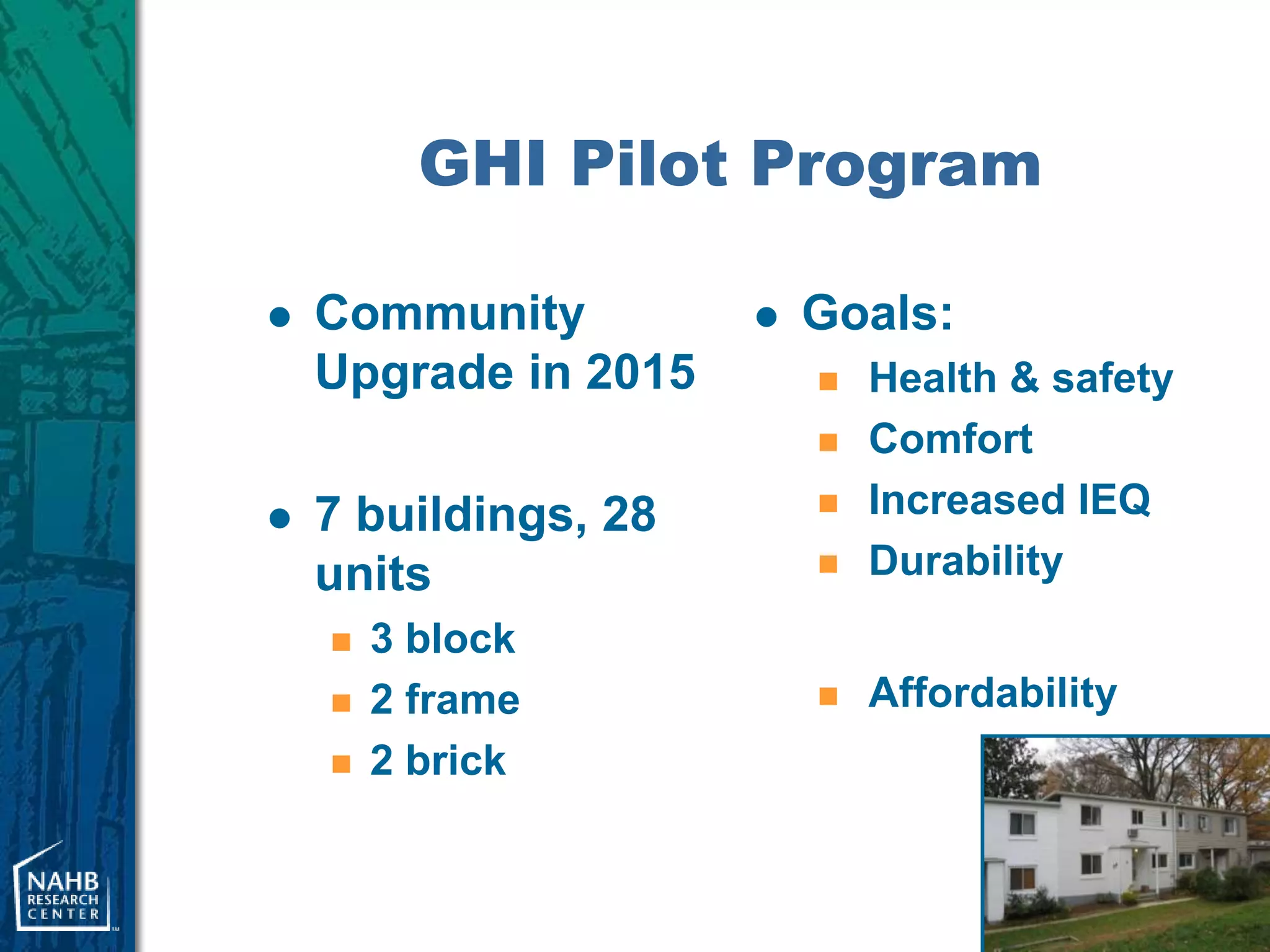

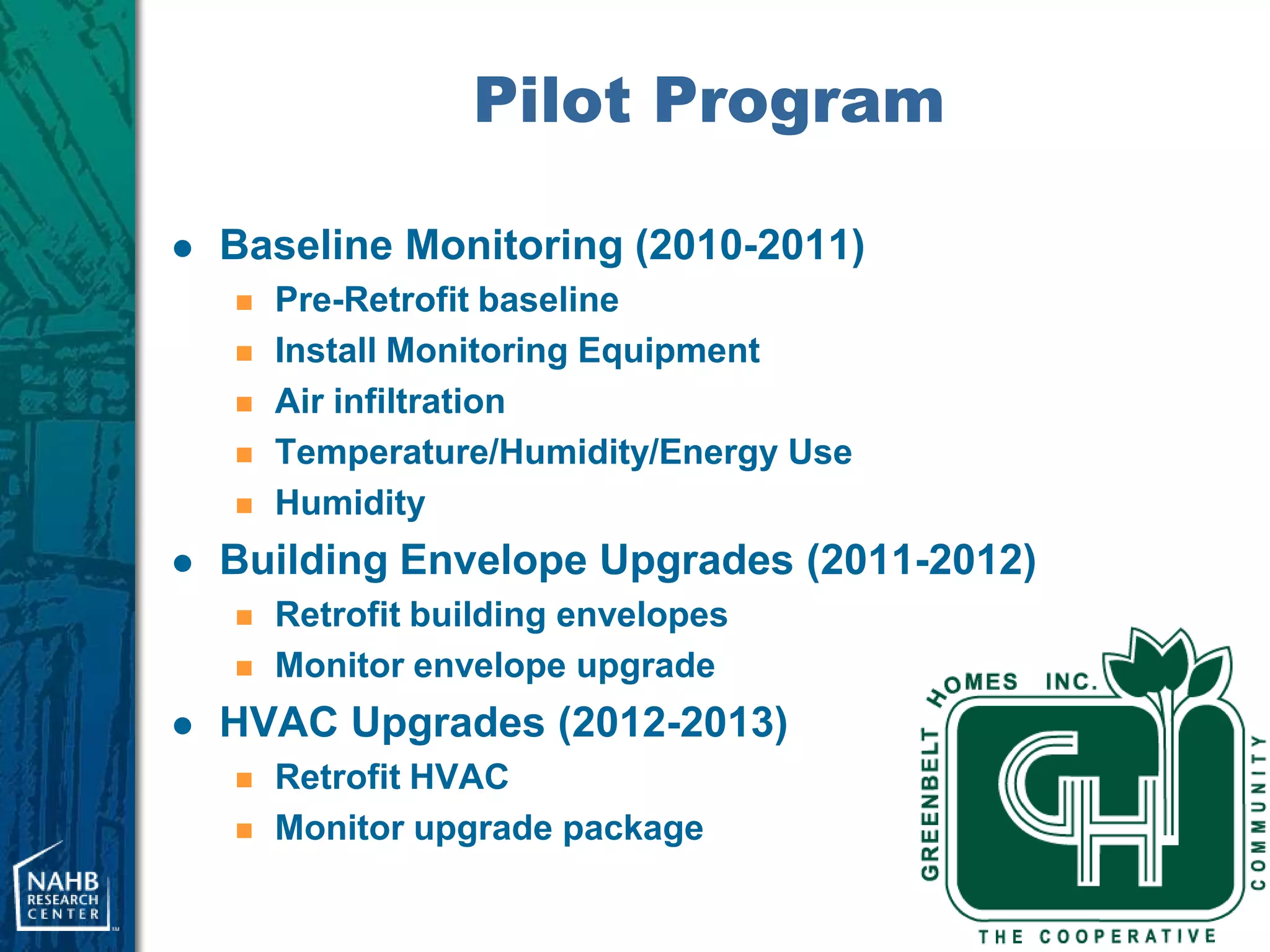

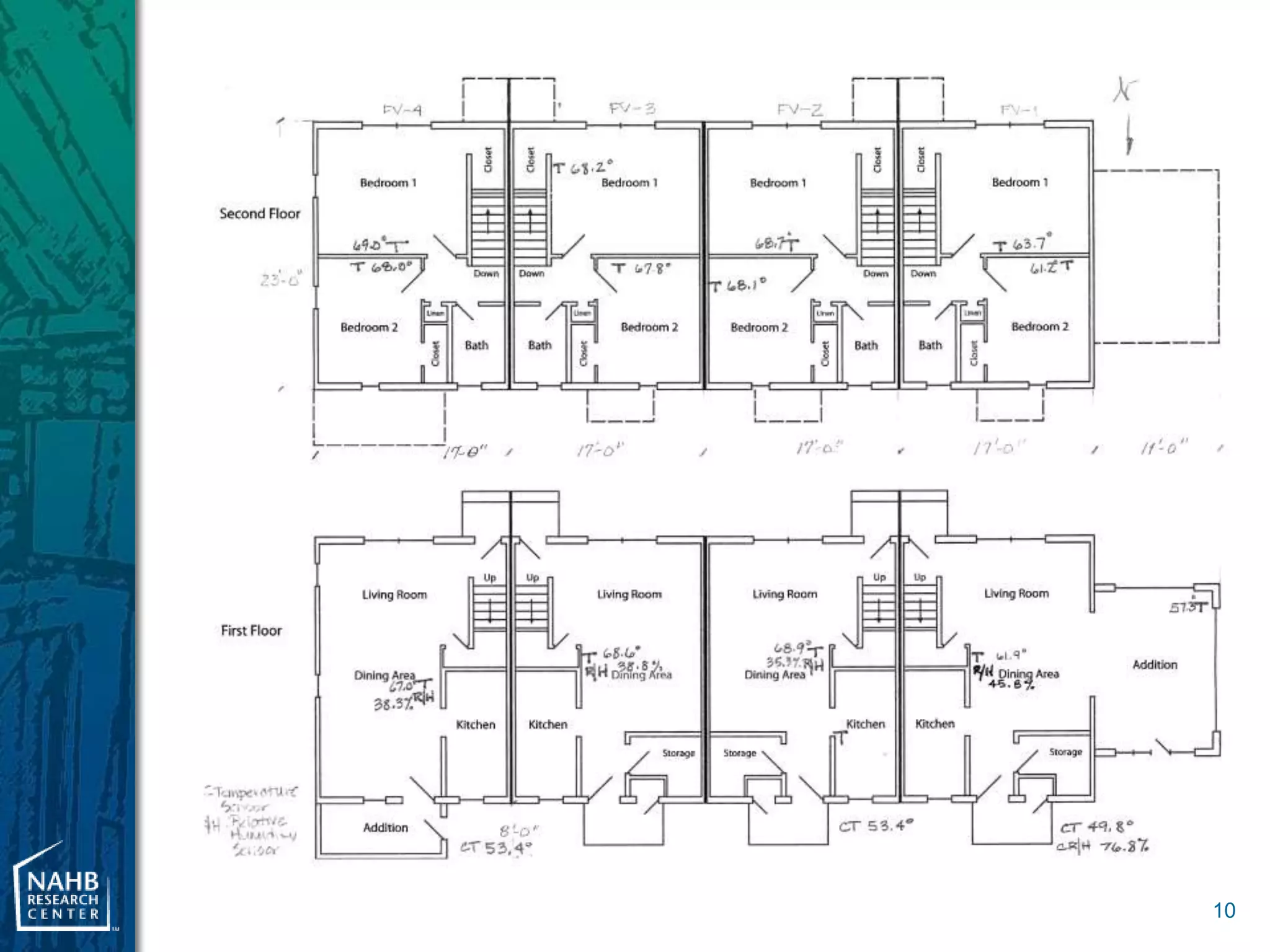

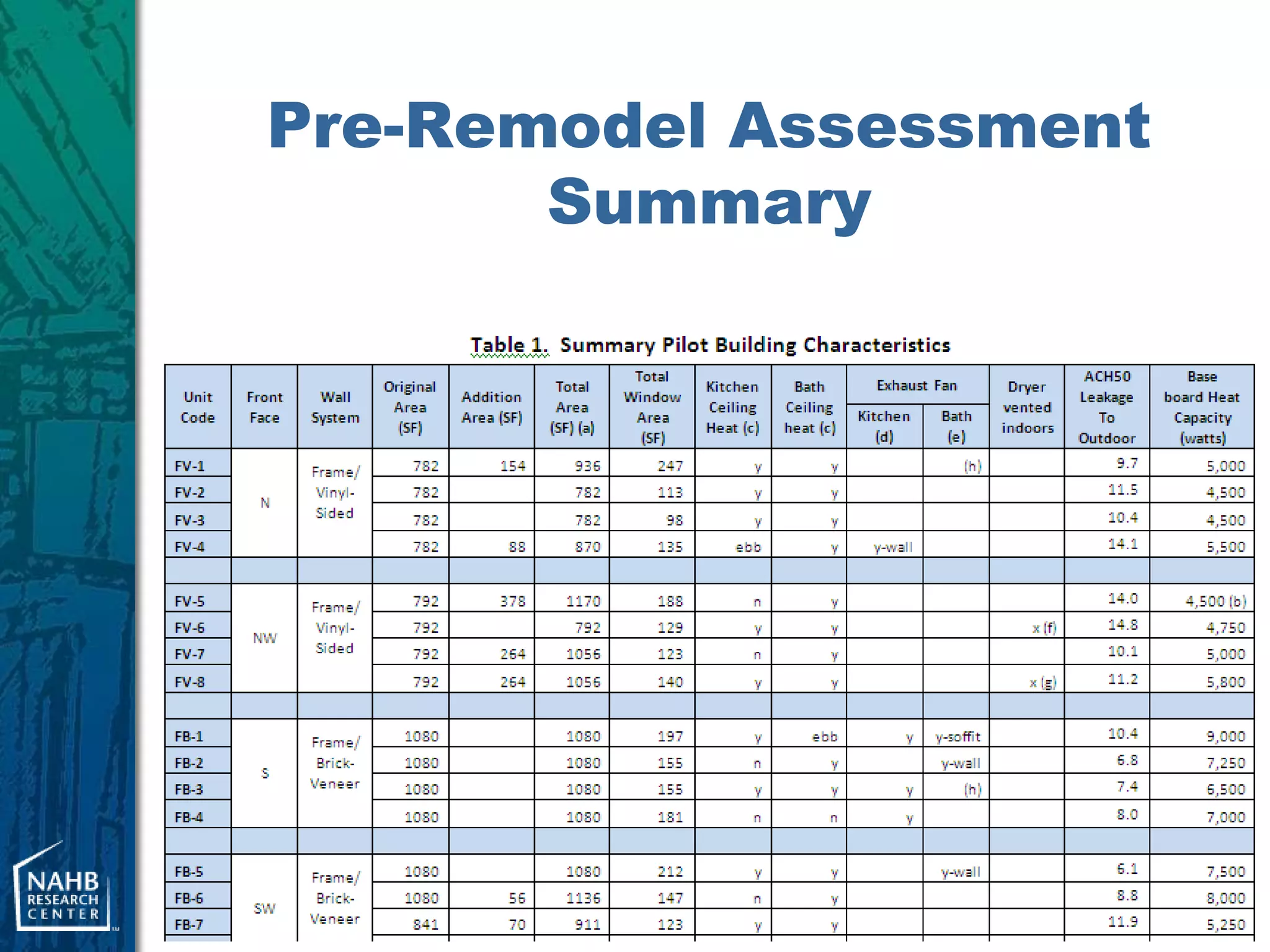

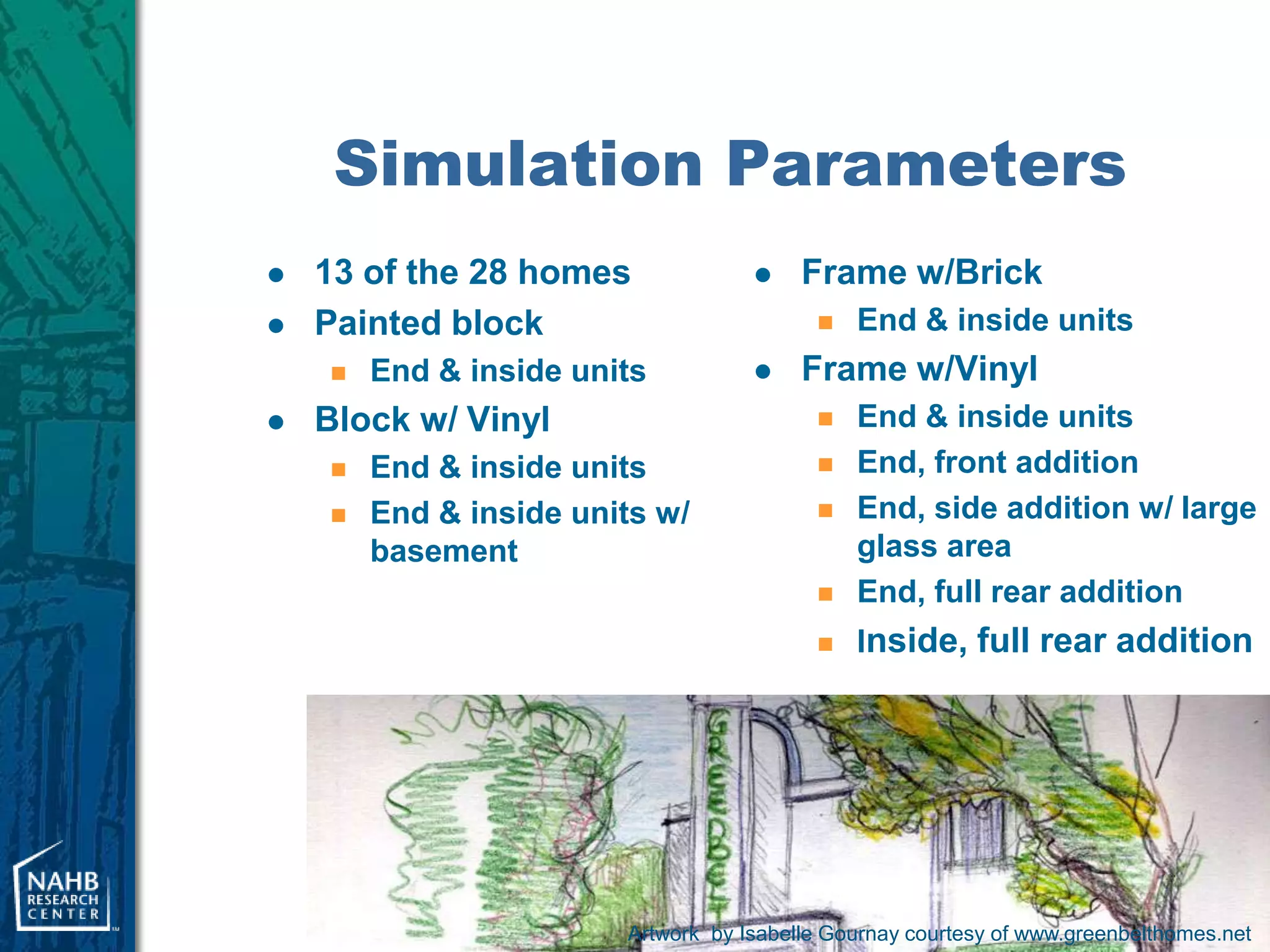

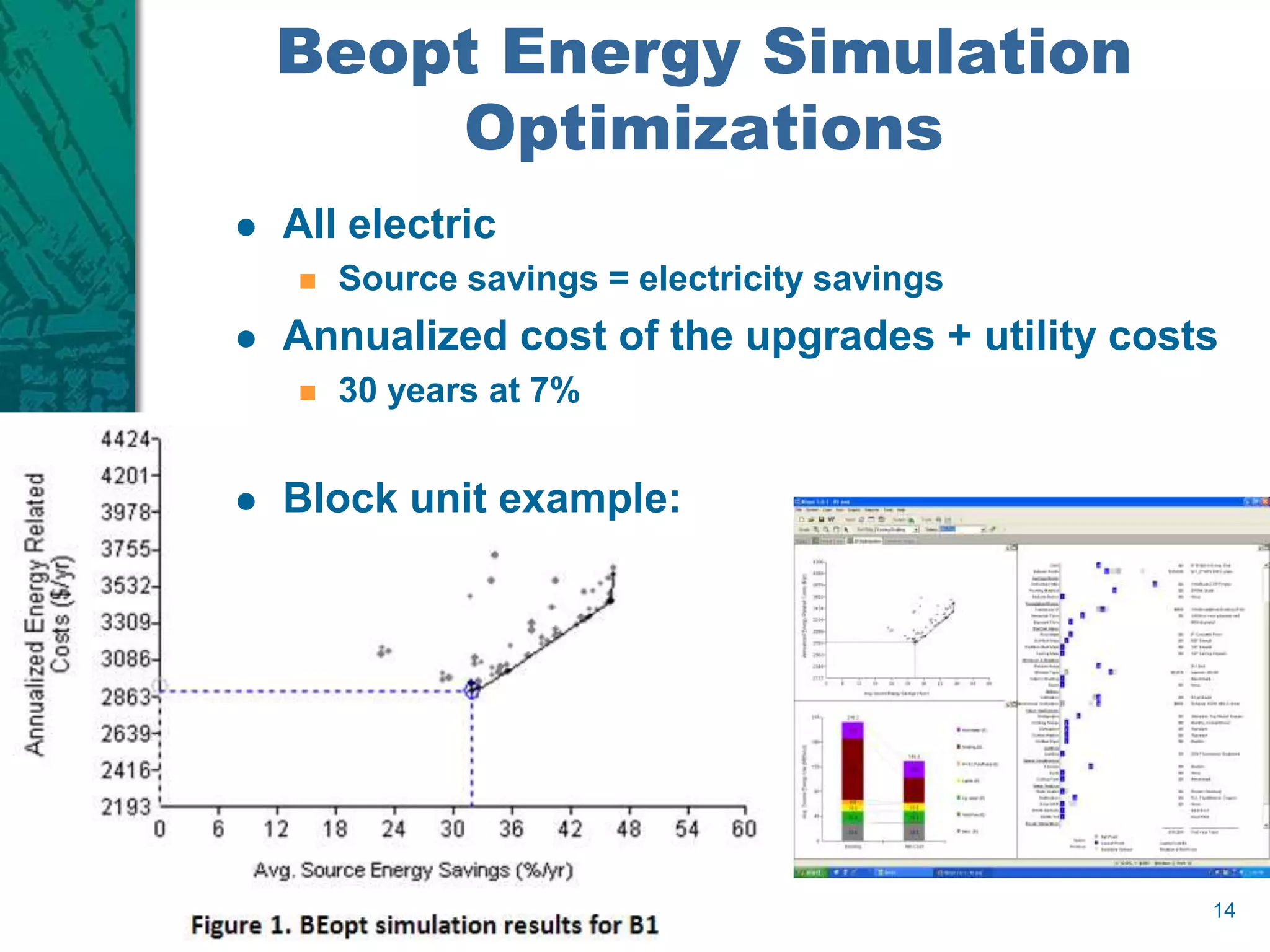

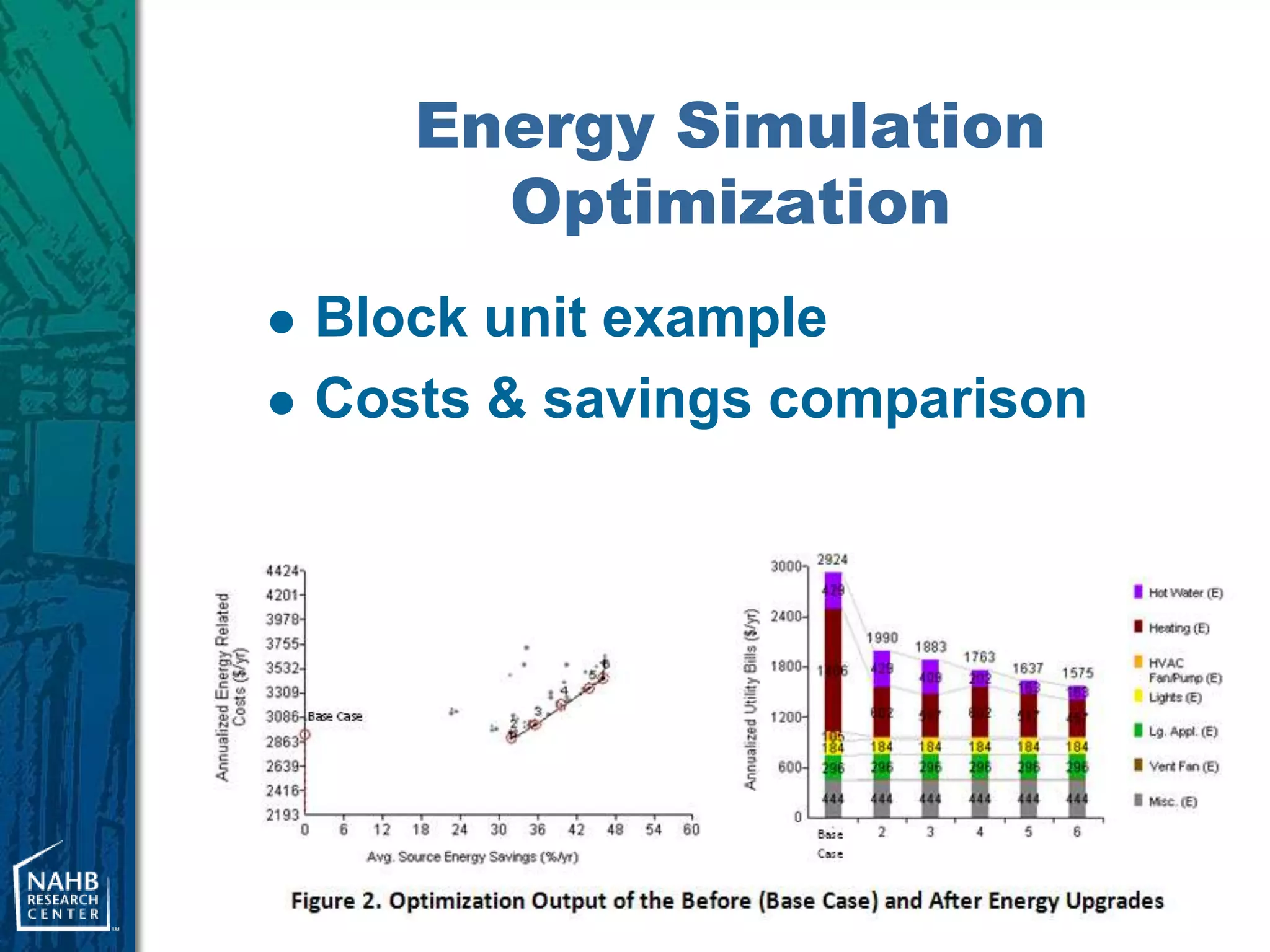

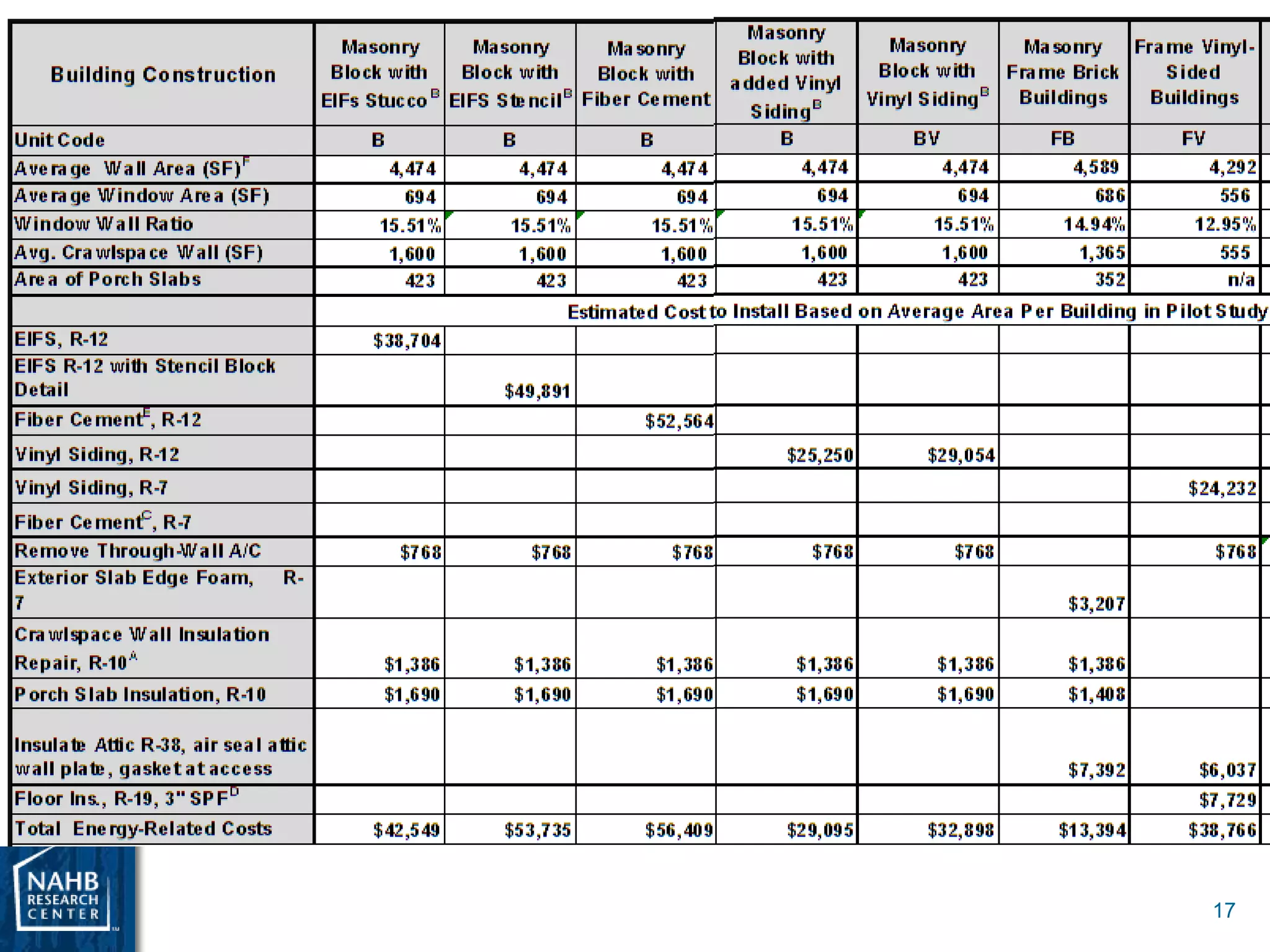

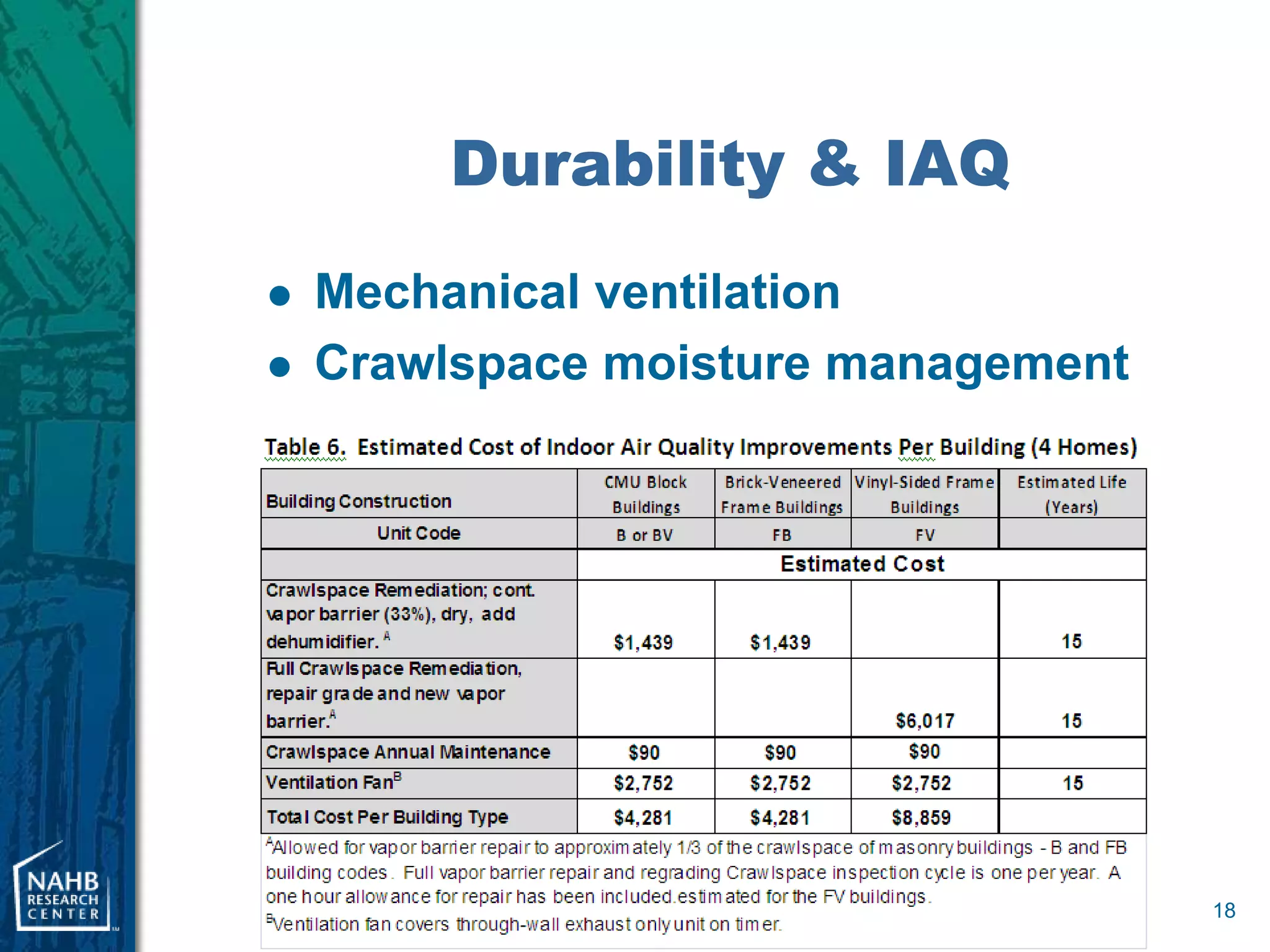

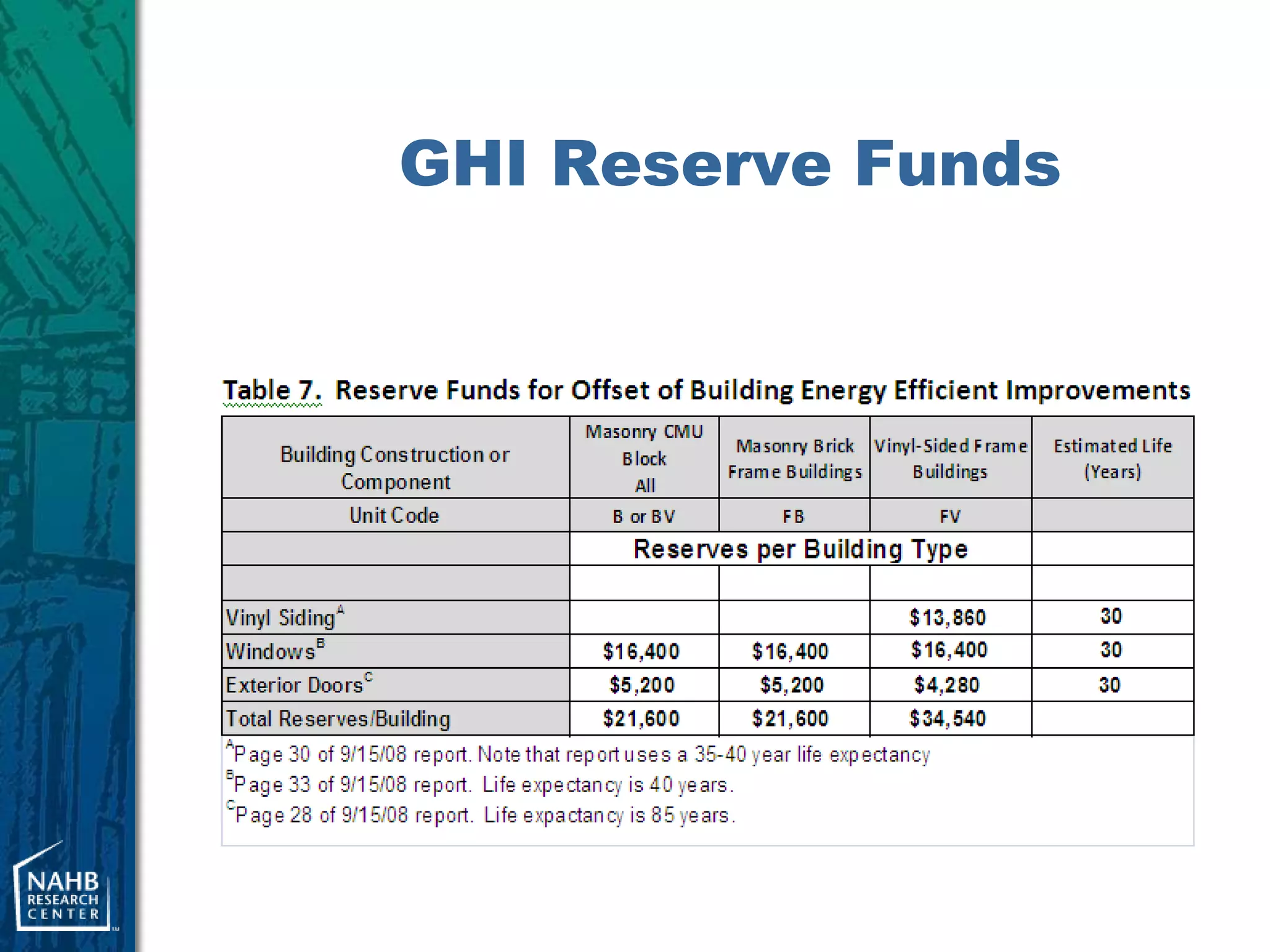

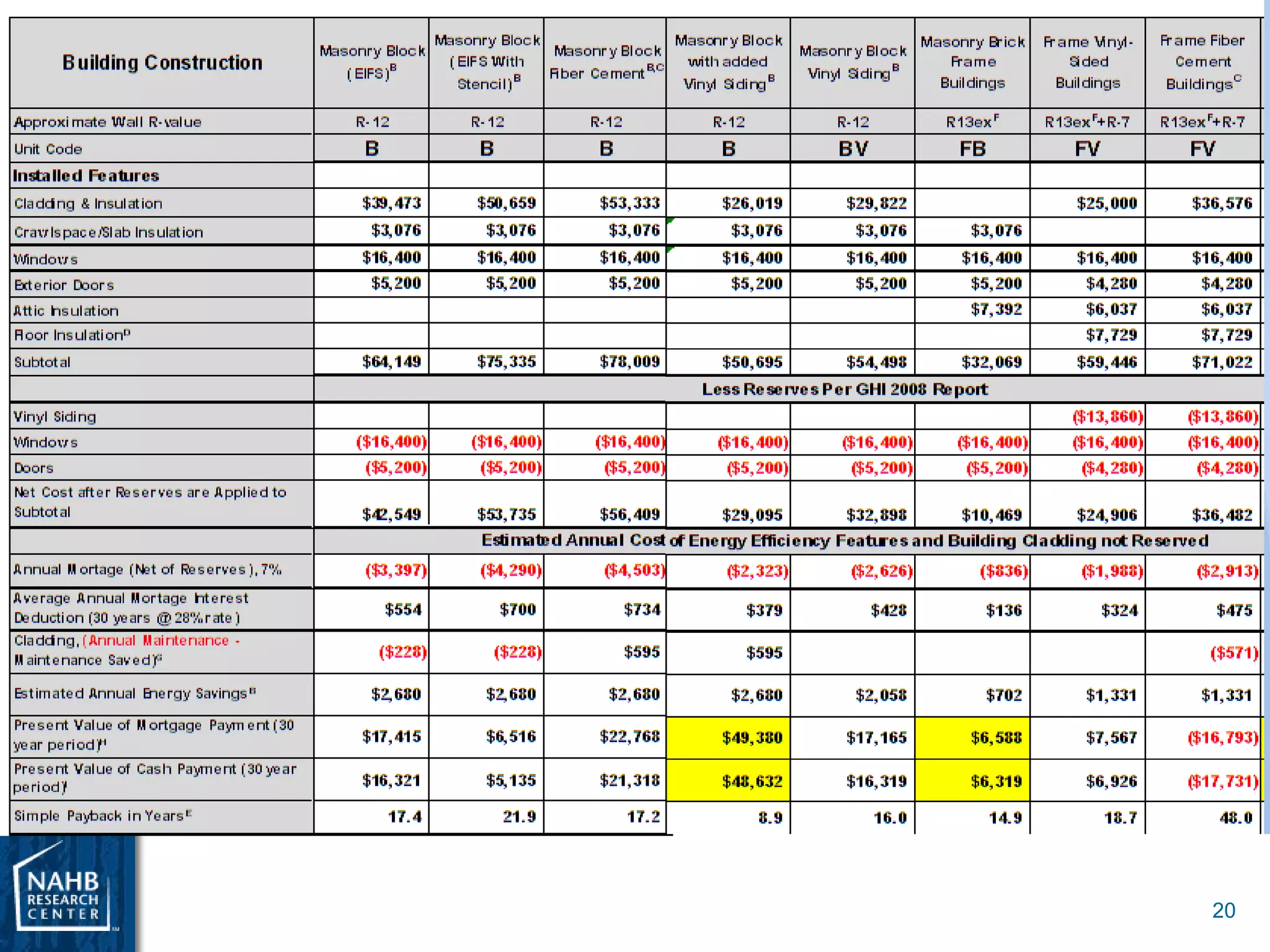

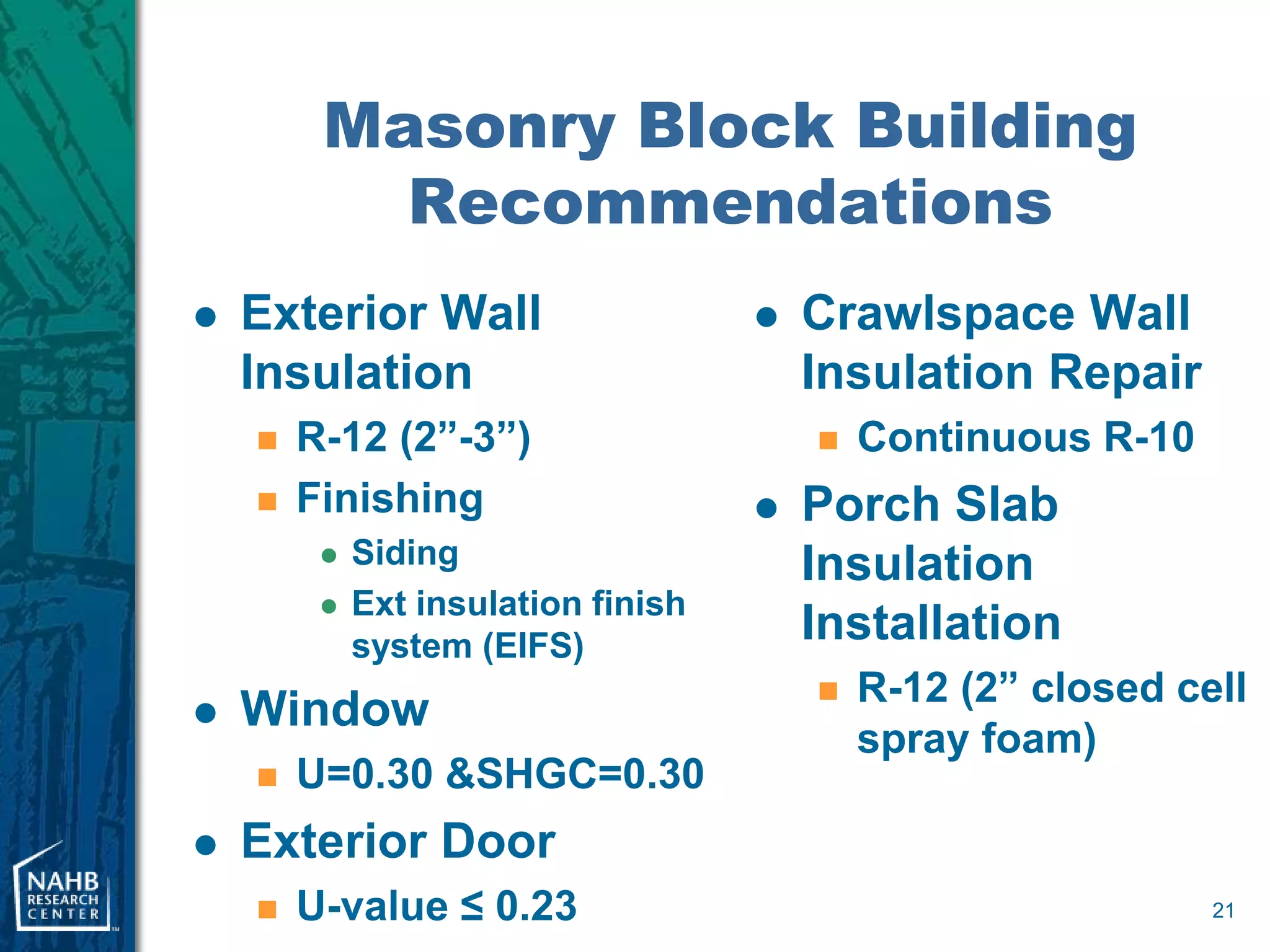

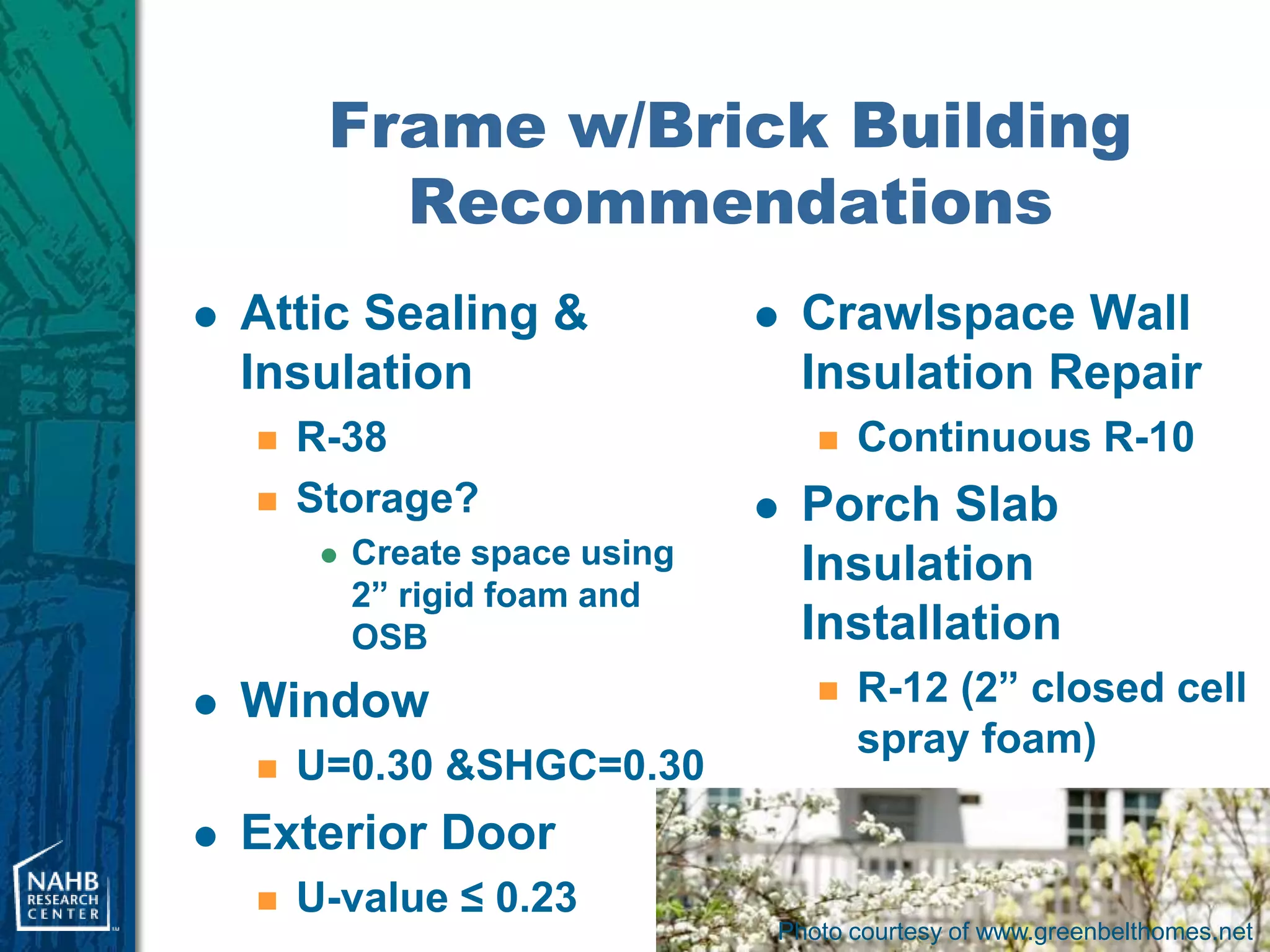

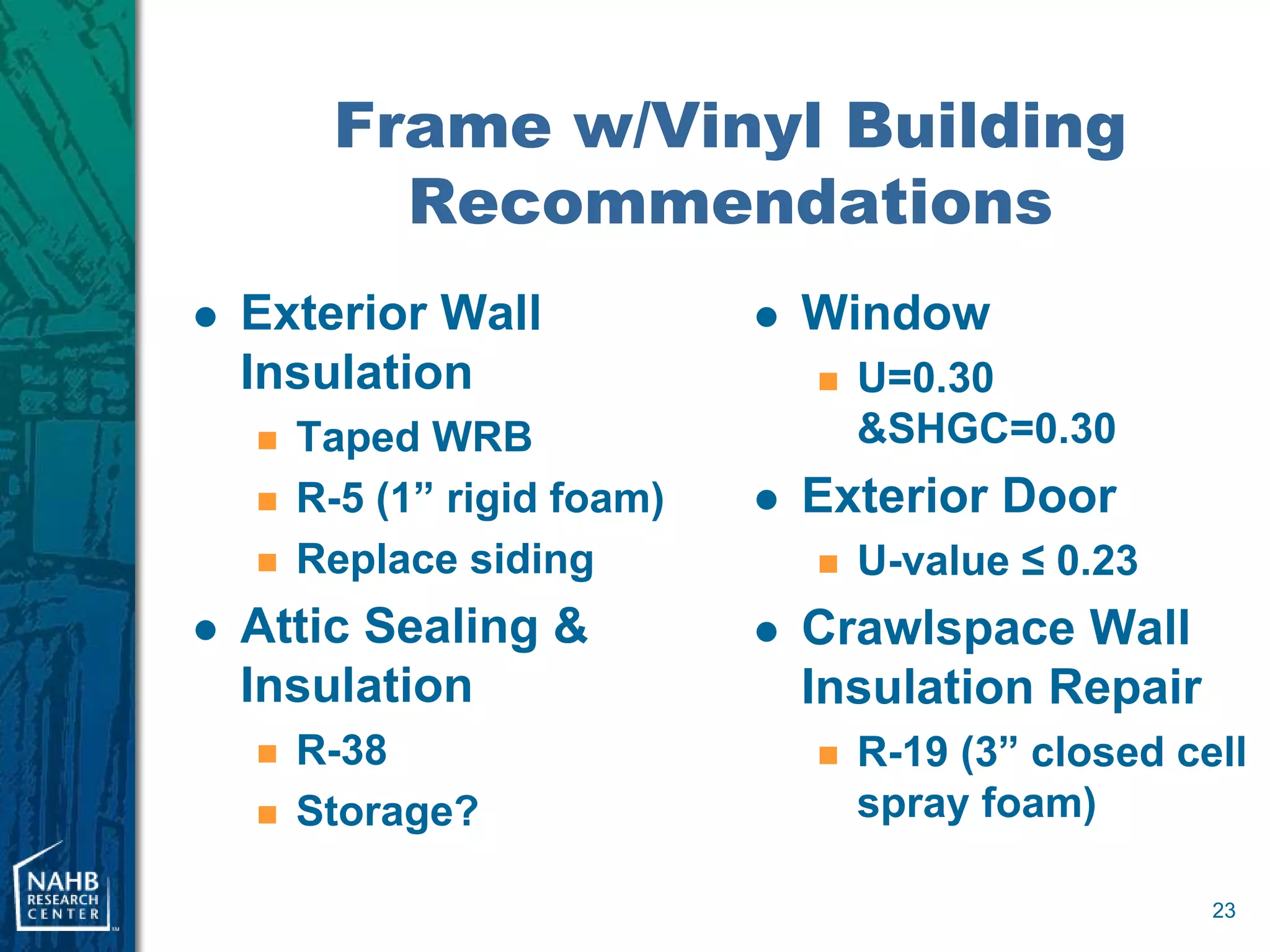

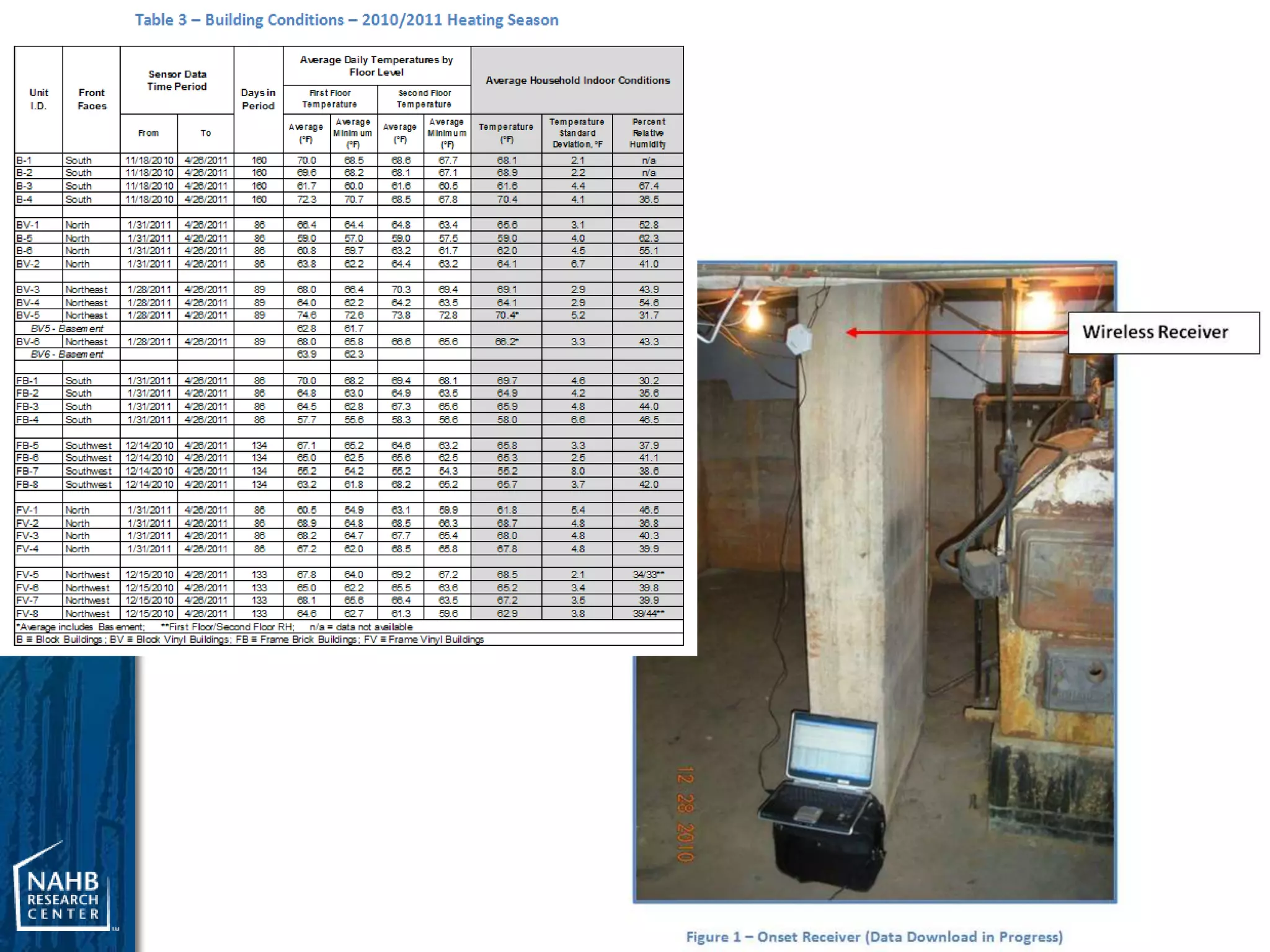

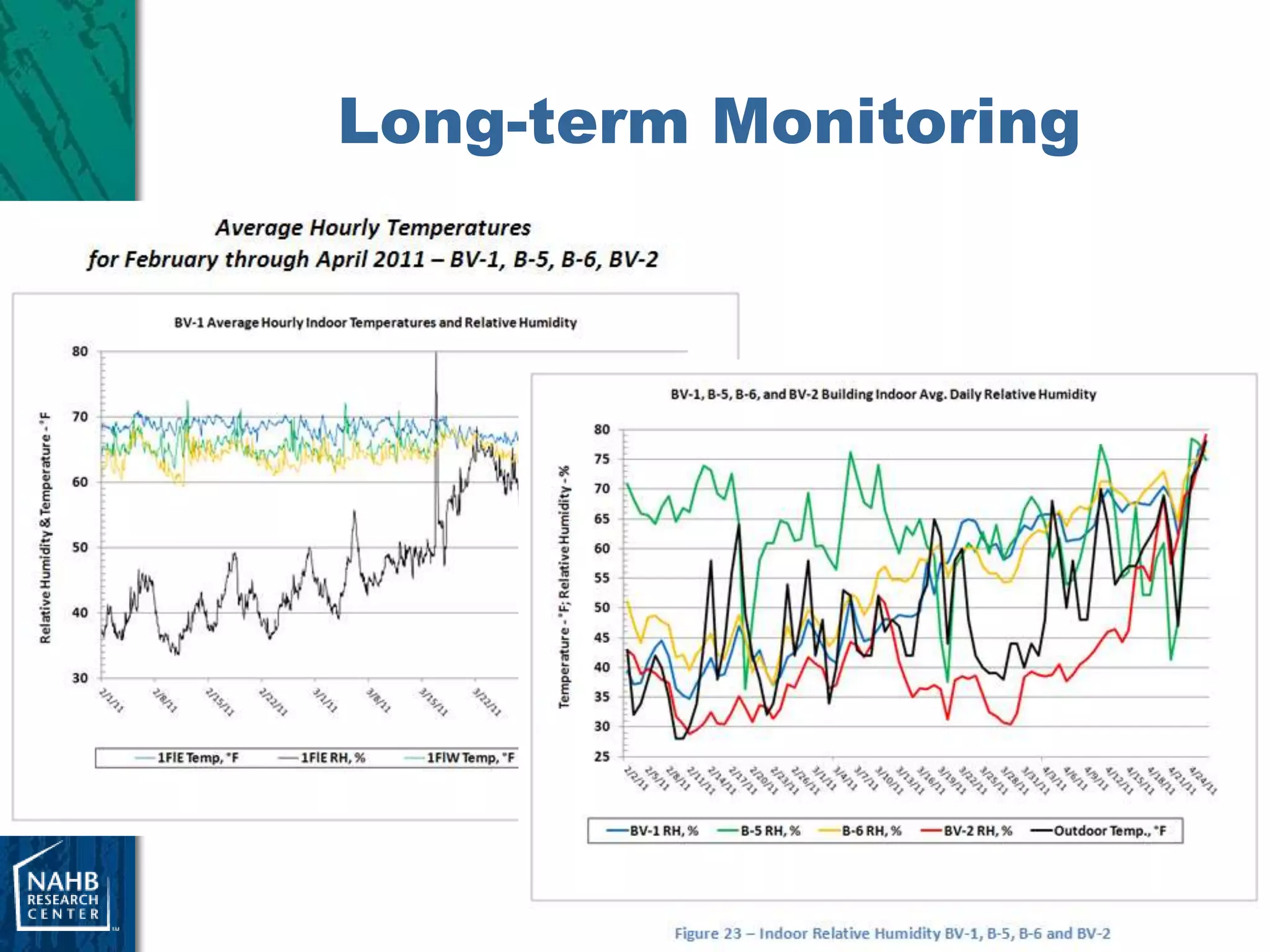

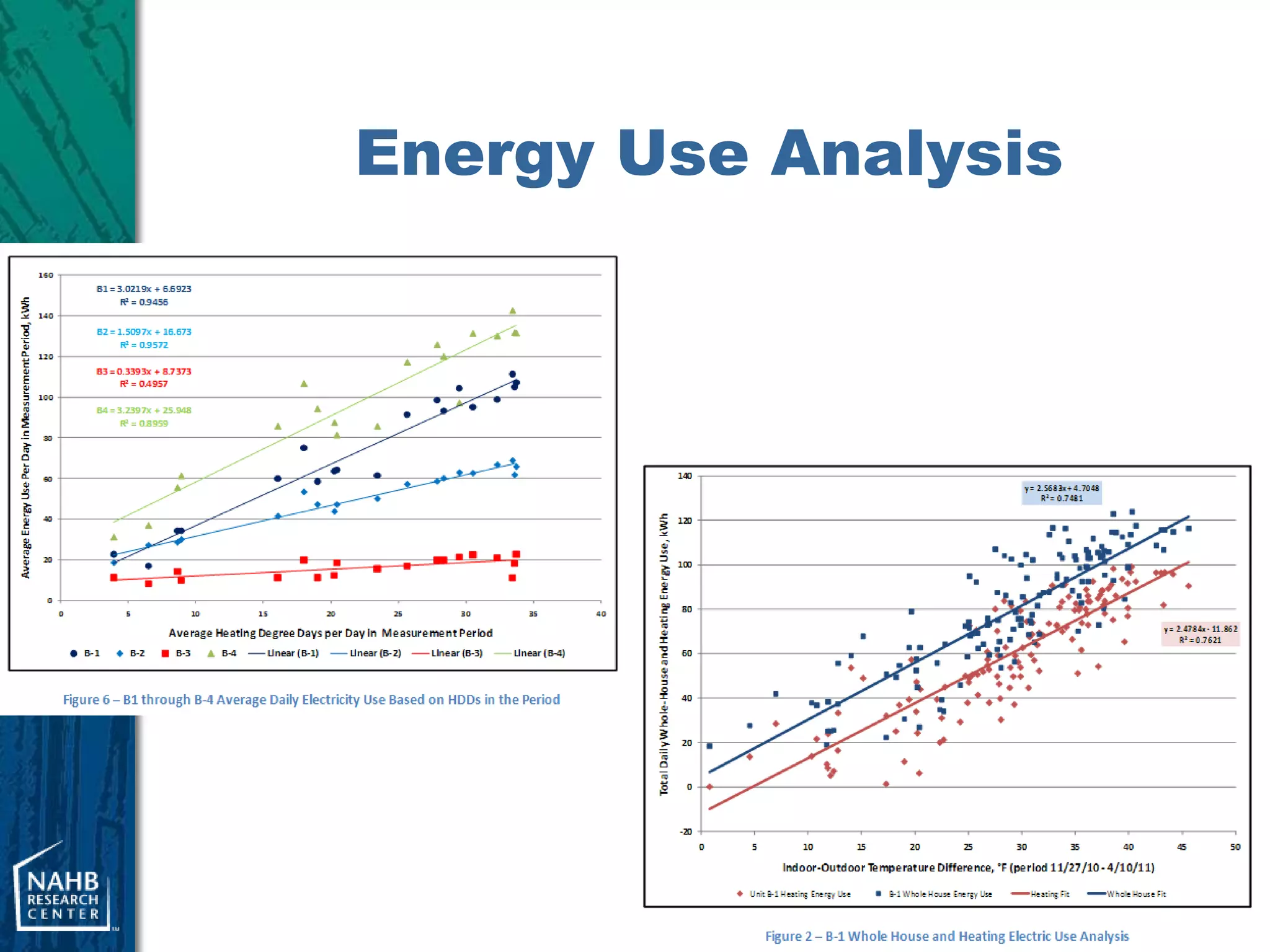

This document summarizes a pilot program to retrofit the buildings and homes of Greenbelt Homes, Inc, a housing cooperative with 1,600 units. Baseline monitoring was conducted of 7 pilot buildings before retrofits. Recommended retrofits included attic and wall insulation, air sealing, high-performance windows and doors, and crawlspace repairs. Energy modeling was used to evaluate retrofit packages. Long-term monitoring will track energy use and performance. The goal is to demonstrate cost-effective solutions that increase comfort, health, efficiency and property value.