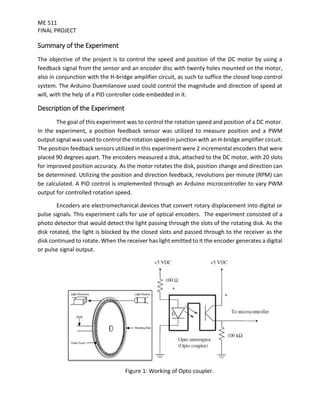

The document summarizes a student project to control the speed and position of a DC motor using closed-loop feedback control. An encoder and sensors measured the motor's position, and an Arduino microcontroller implemented PID control to vary the motor's PWM signal based on errors between the measured and desired position/speed. Key components included an H-bridge motor driver, encoder, sensors, and a 3D printed mounting base designed by the students. Diagrams depict the control system circuitry and 3D models.