The document summarizes a university capstone project to design and build a robotic welding cell. Key details include:

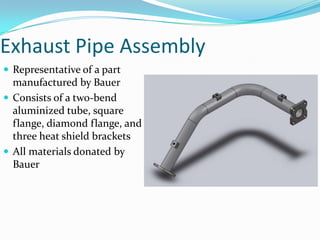

- The project involved designing a semi-automatic welding cell using a robotic welder to manufacture exhaust pipe assemblies for Bauer Welding and Metal Fabricators.

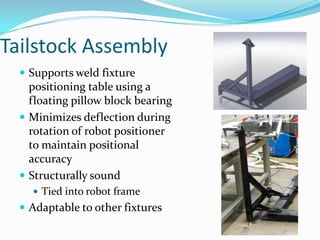

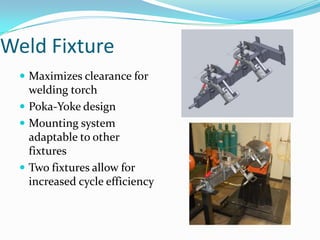

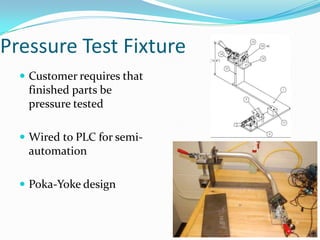

- Various fixtures were designed and built to securely hold parts for welding, dimensional checks, and pressure testing.

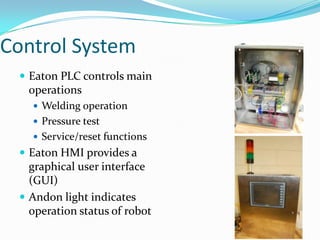

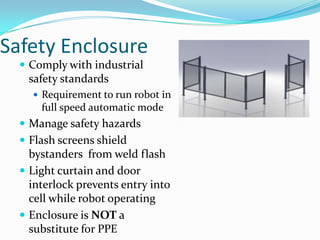

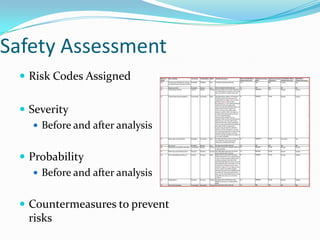

- Automation and safety systems like a PLC, safety enclosure, and light curtain were incorporated to enable safe, repeatable robotic welding of parts.

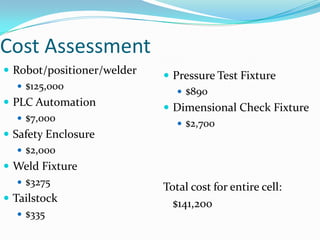

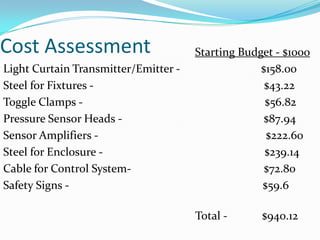

- The completed cell cost $141,200 and demonstrated the viability of the pulsed GMAW welding process developed in the previous capstone for production applications.