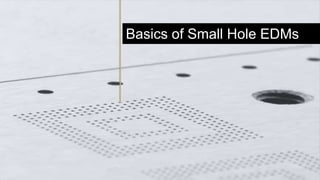

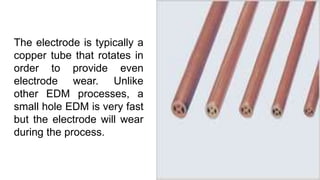

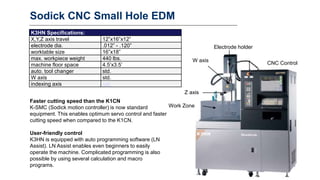

Small hole EDMs, also called hole poppers, are used to erode small diameter holes from .012" to .120" through conductive materials like metals. The rotating copper tube electrode provides even wear during the fast but erosive process. They are commonly used for start holes and complex turbine blade bores. Key specifications for the Sodick K1C and K3HN small hole EDM models include travel sizes, electrode diameters, workpiece weights, and optional CNC or auto tool changing features. Common questions when purchasing include power needs, installation, training, and sourcing consumables like electrodes, guides, and dielectric fluid.