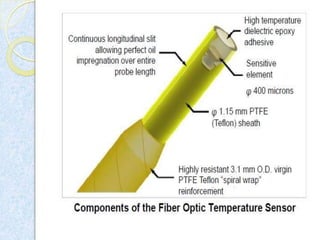

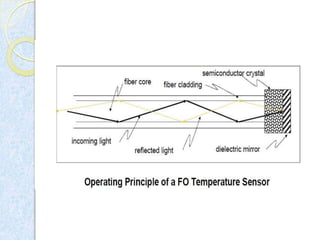

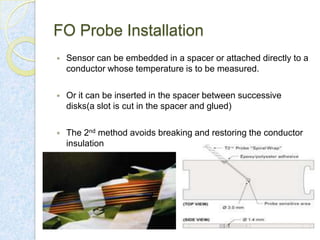

This document discusses fiber optic sensors for measuring the hot spot temperature of transformer windings. It begins by explaining that the winding temperature is not uniform, with hot spots limiting the transformer's loading capacity, and that conventional measurement methods make assumptions. It then discusses how fiber optic sensors were previously neglected due to fragility and cost but now offer advantages like reliability. Recent developments have created more robust fiber optic probes using GaAs technology. The document explains how the sensors work and details their specifications, installation process, and concludes that fiber optic sensors will likely be widely used for transformer monitoring.