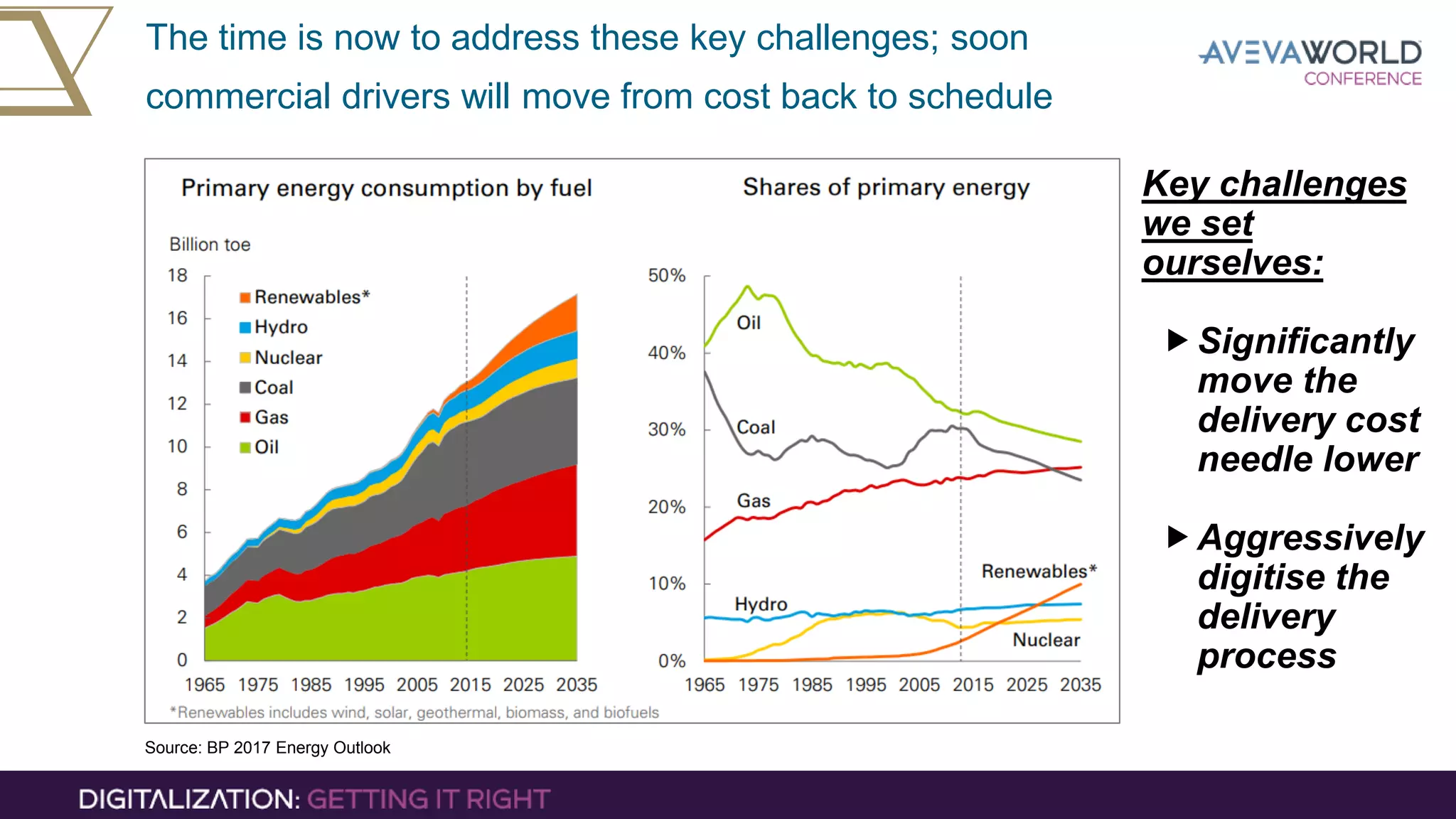

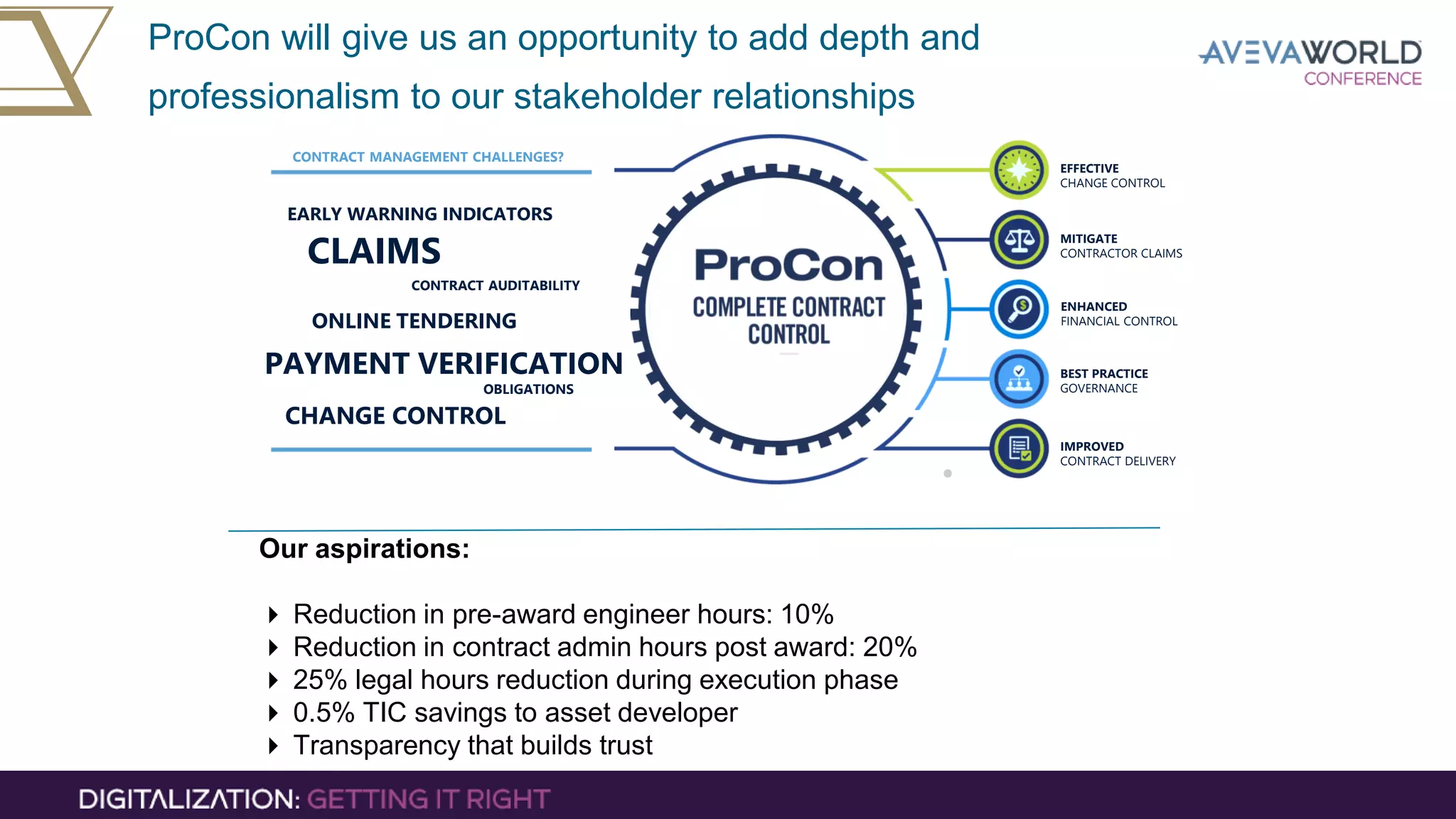

The presentation discusses how WorleyParsons aims to optimize asset management by utilizing operational data environments and emerging technologies amidst challenges in the hydrocarbons sector. It outlines key objectives for 2018, focusing on reducing delivery costs and improving efficiency through better data management and contractor relationships. Additionally, the document emphasizes the importance of digital transformation in improving project outcomes and delivering value to stakeholders.