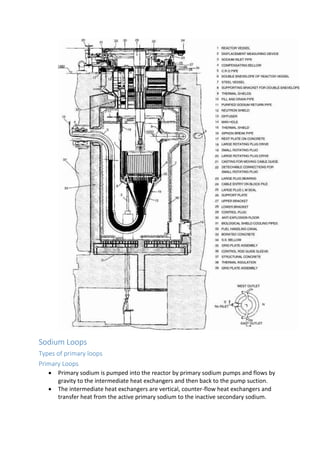

The report presents an overview of the Fast Breeder Test Reactor (FBTR), a sodium-cooled fast reactor conceptualized as part of India's three-stage nuclear power program. It details the reactor's core design, assembly, and the mechanisms for sodium and water leak detection, safety control, and power generation. Additionally, the report discusses the auxiliary systems, fuel handling, and electrical supply methods for ensuring the reactor's operational safety and efficiency.