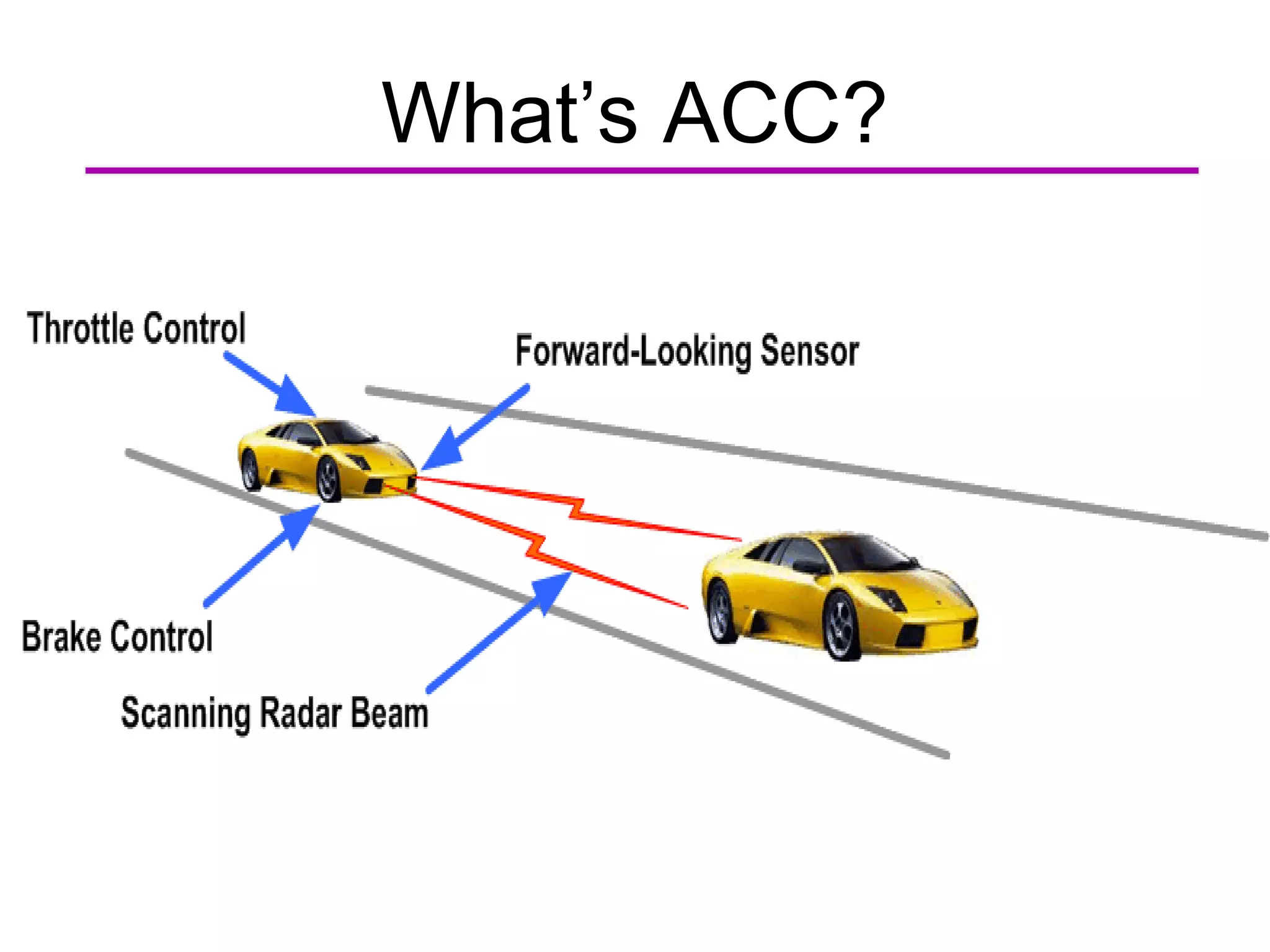

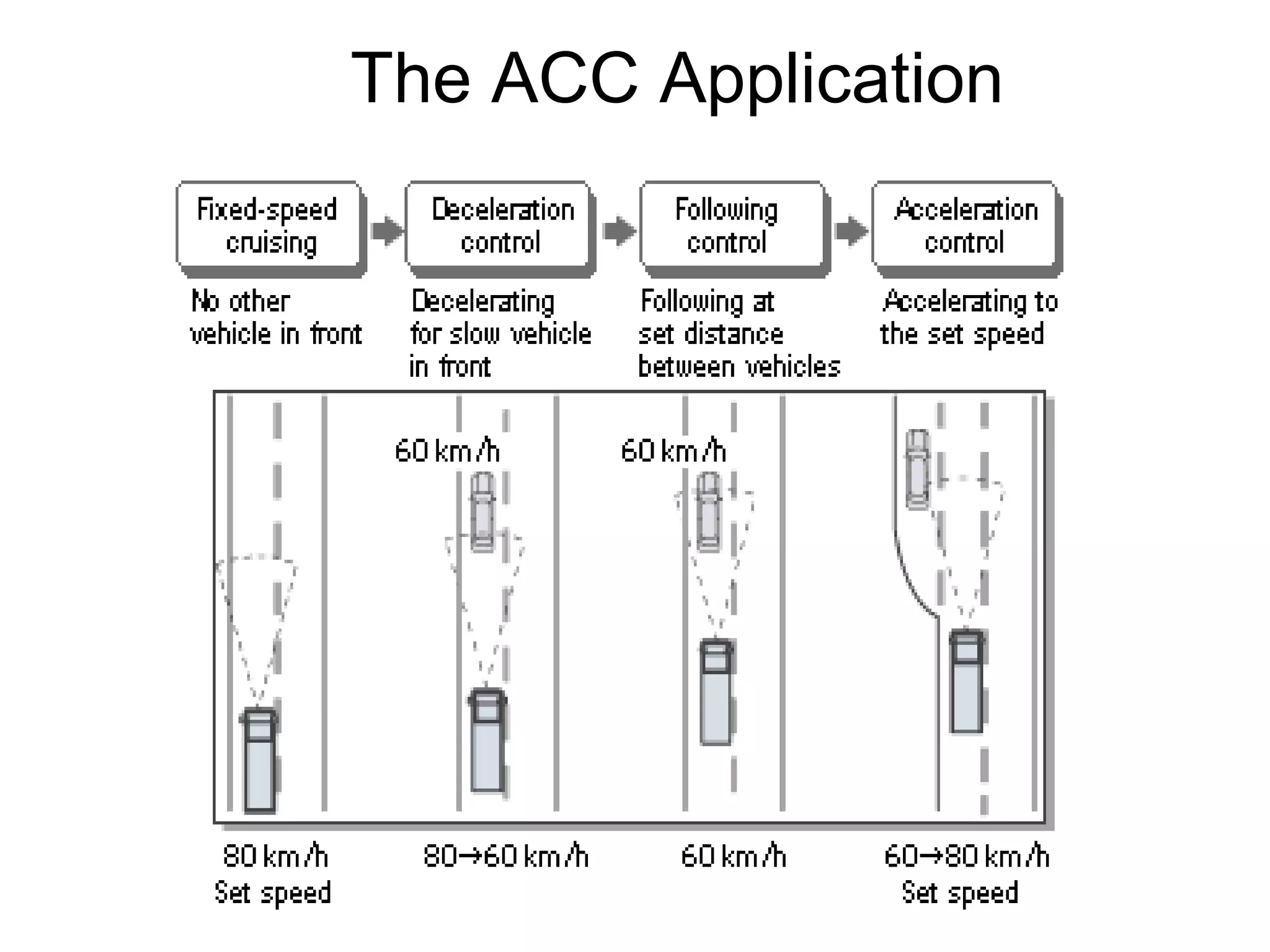

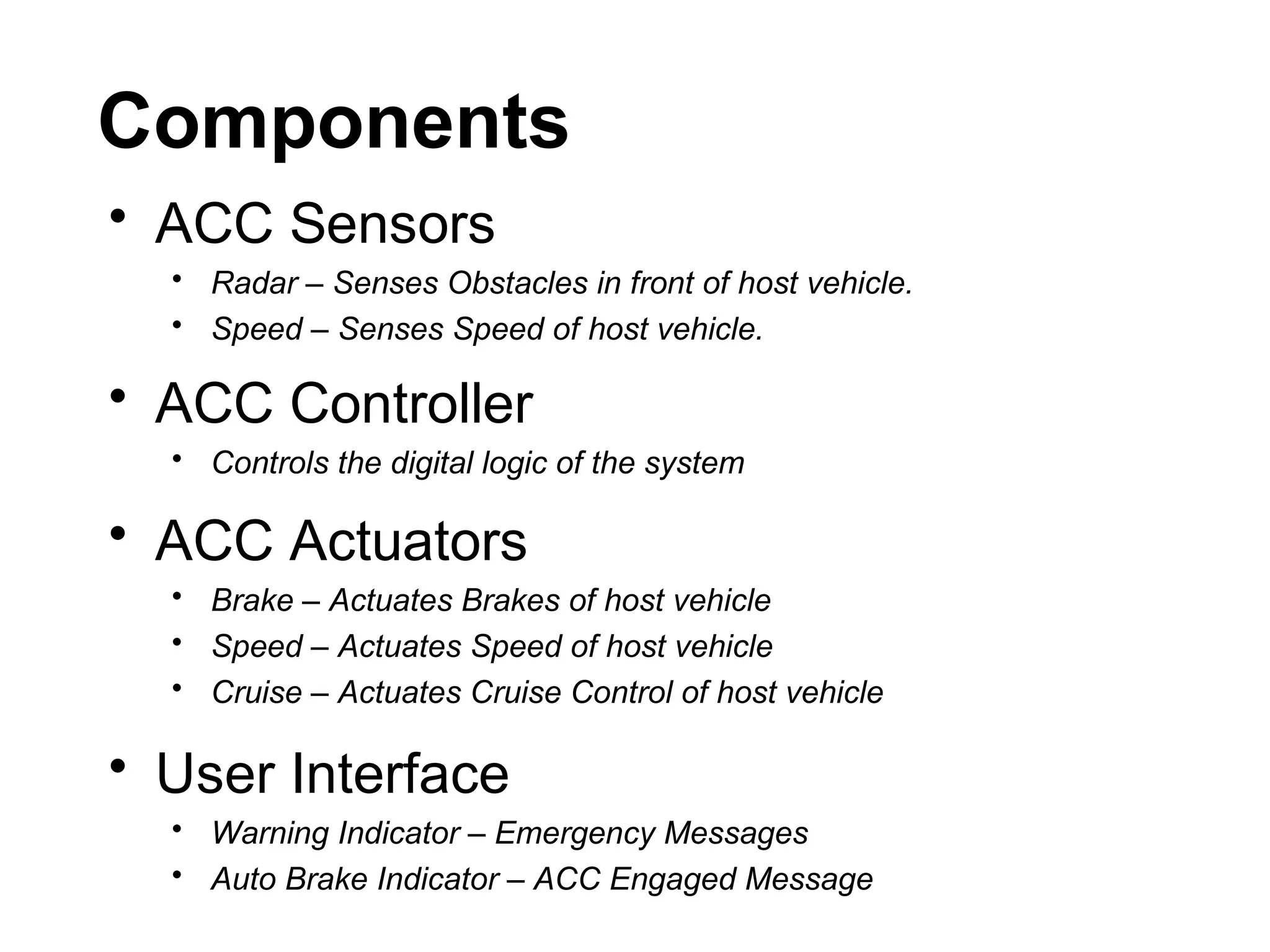

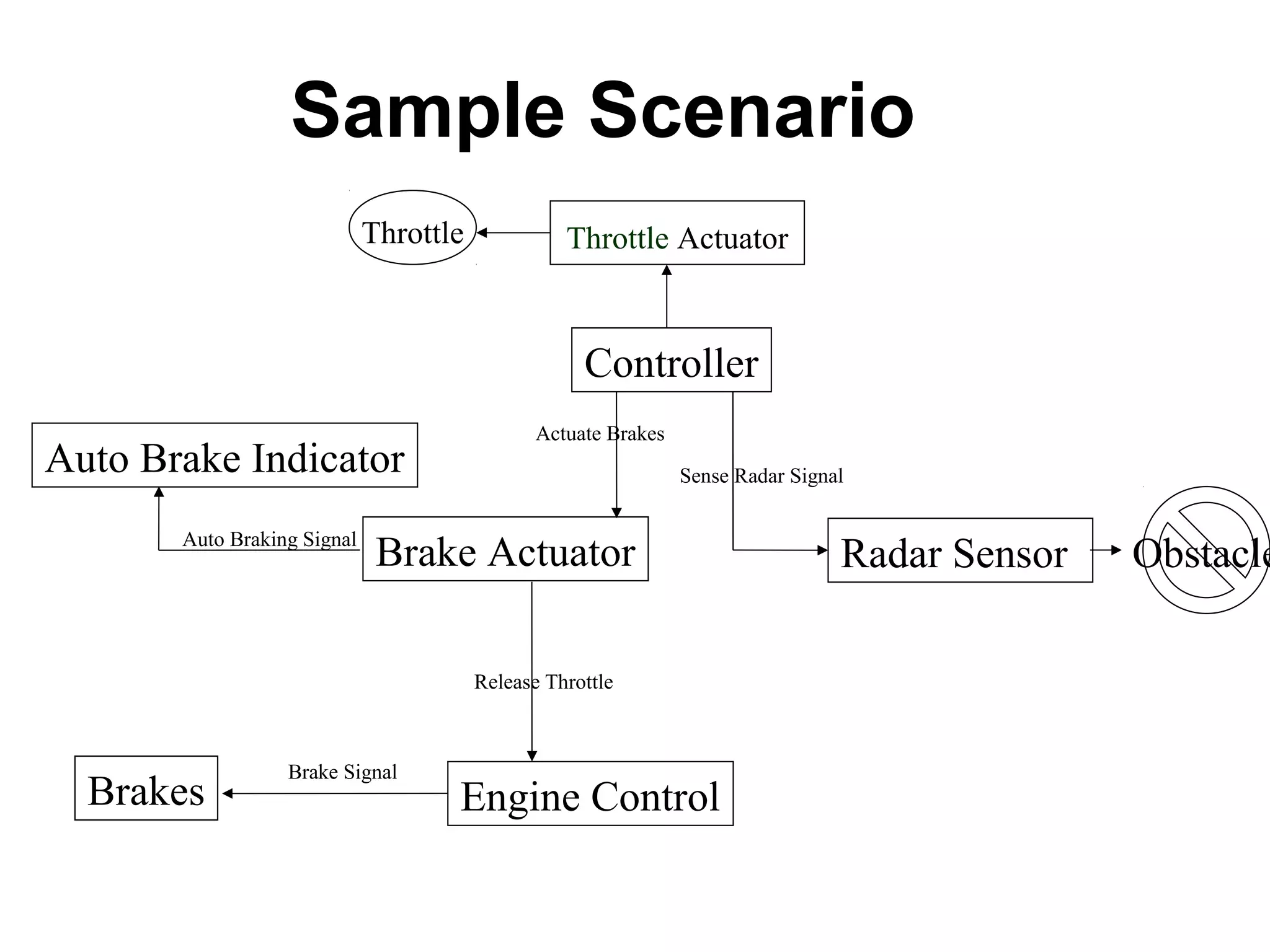

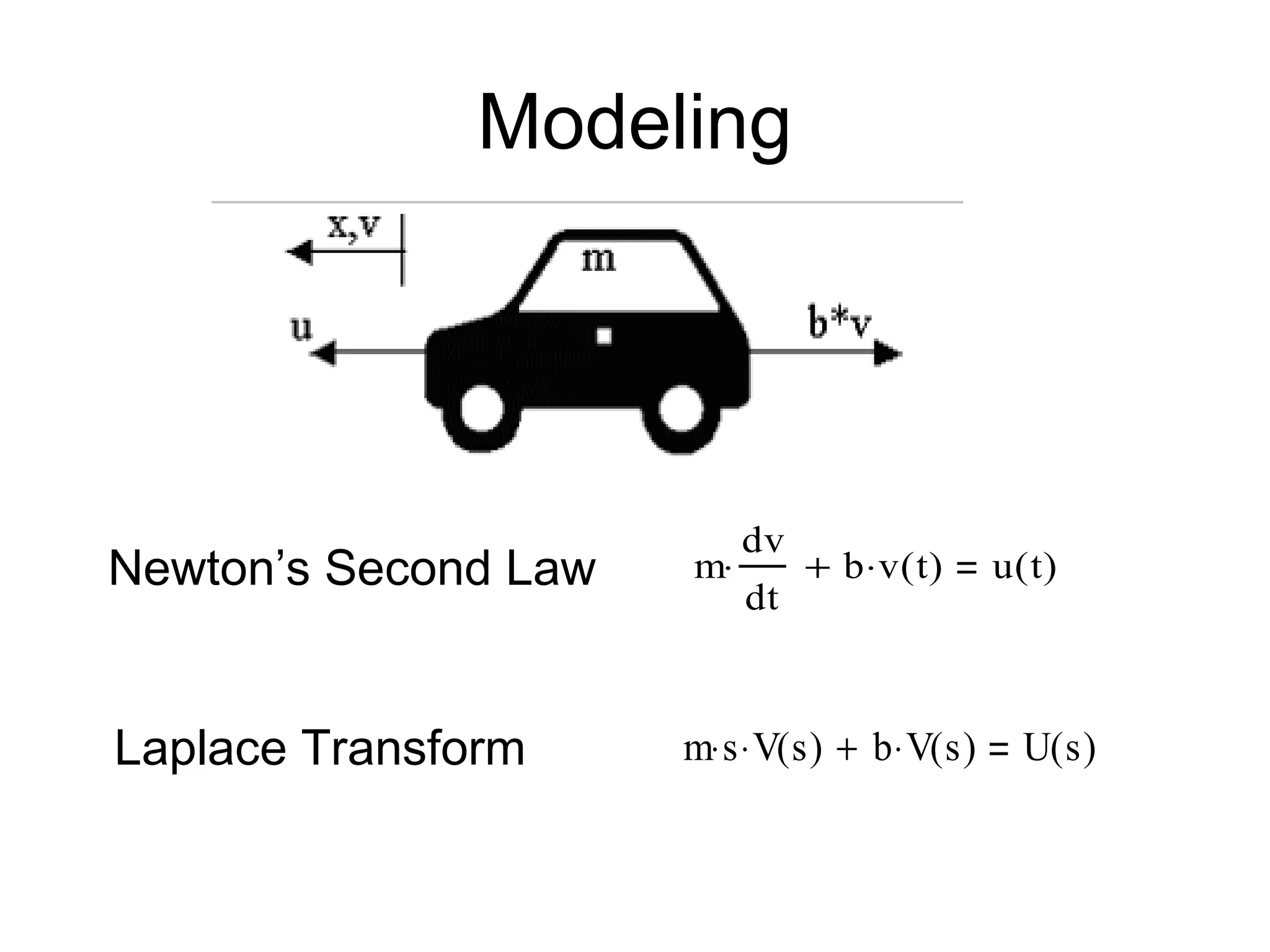

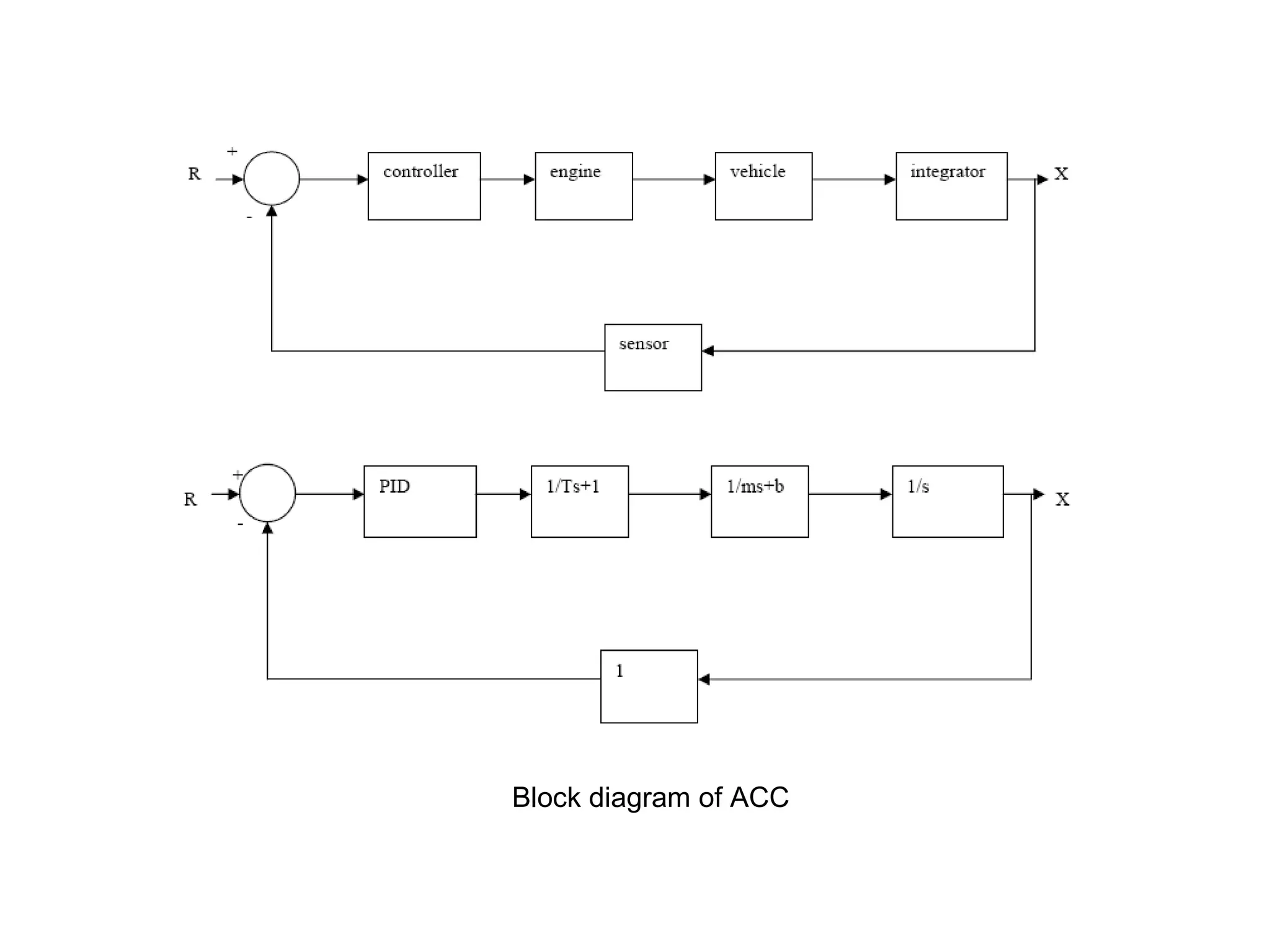

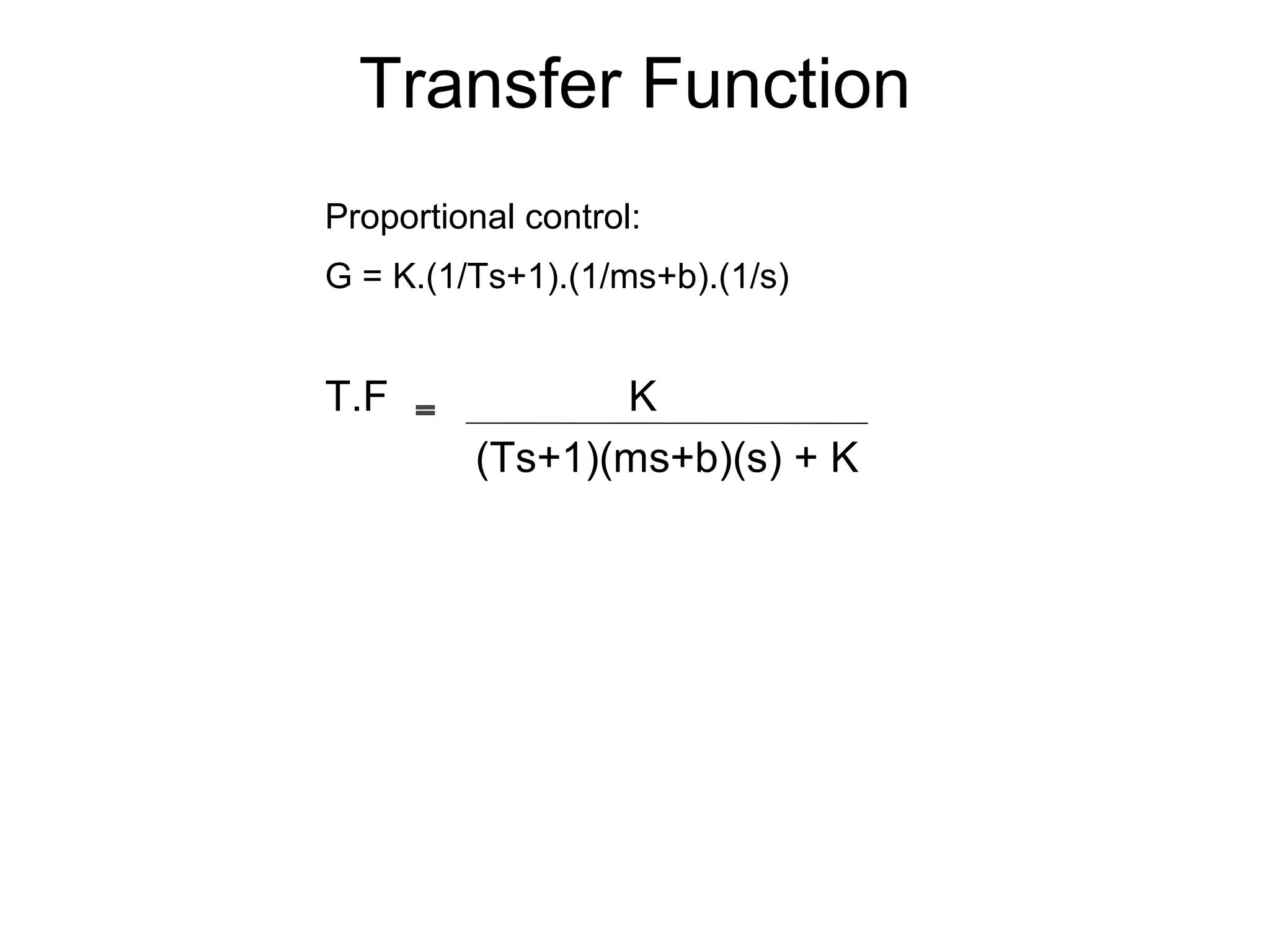

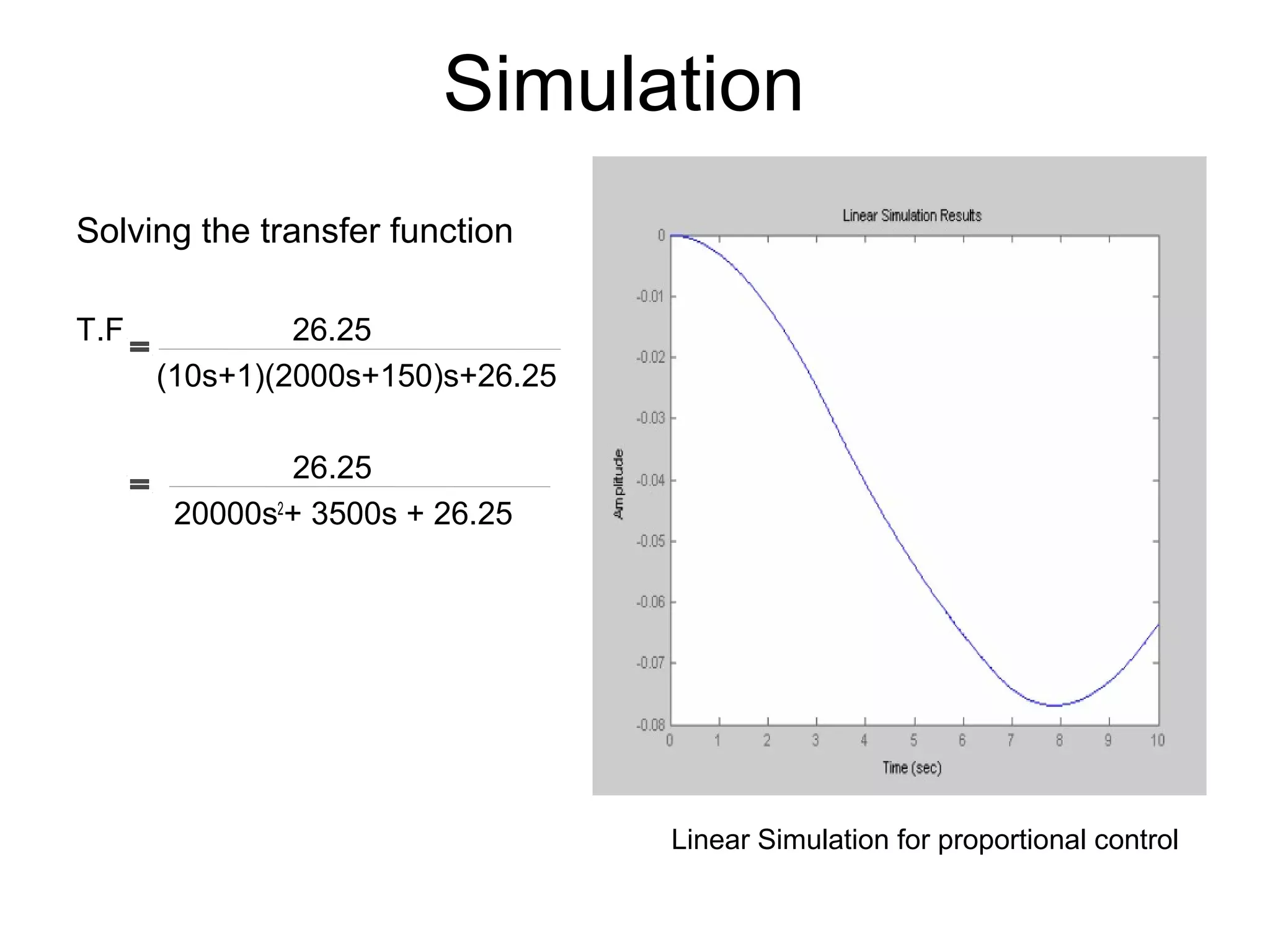

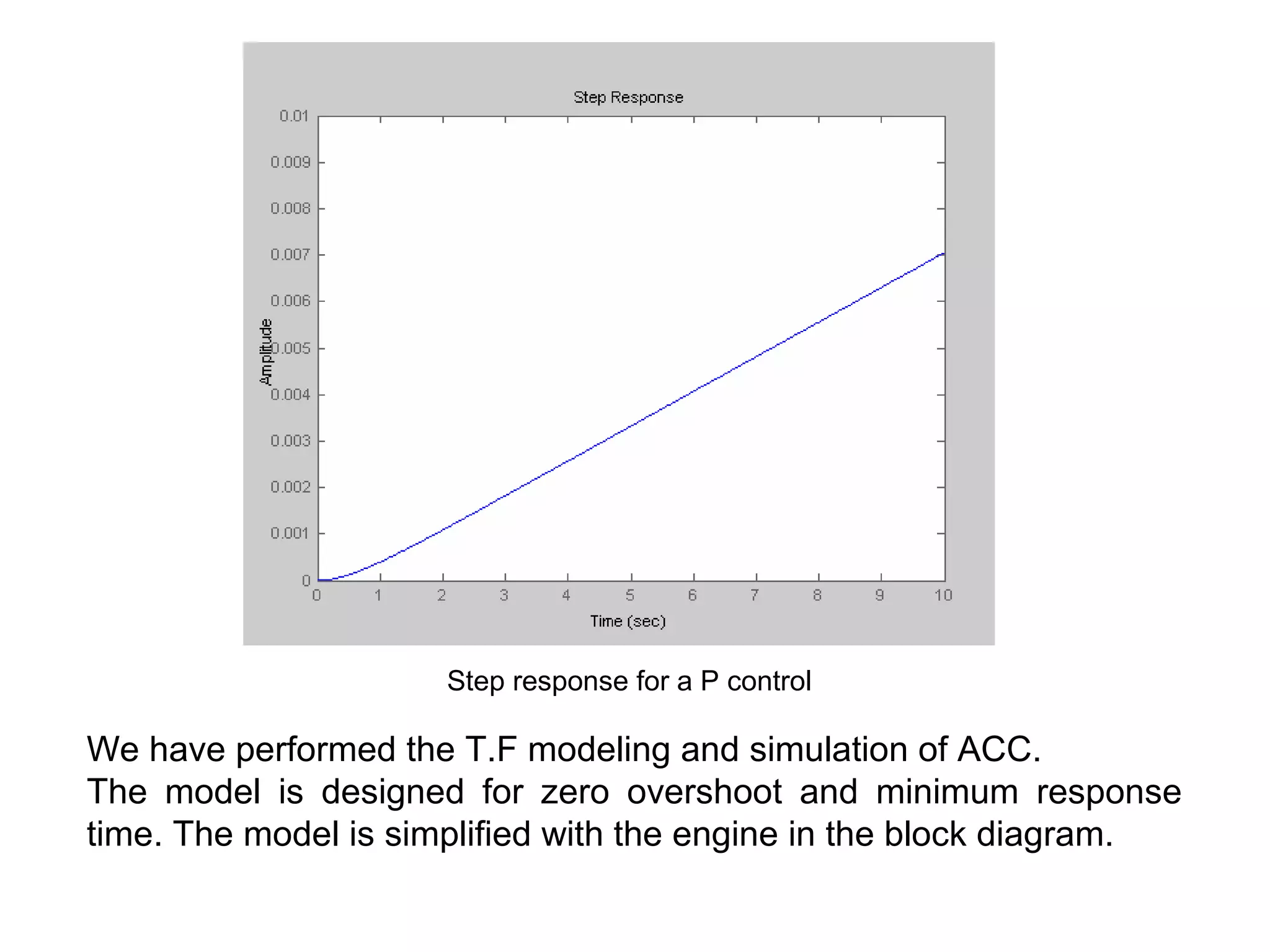

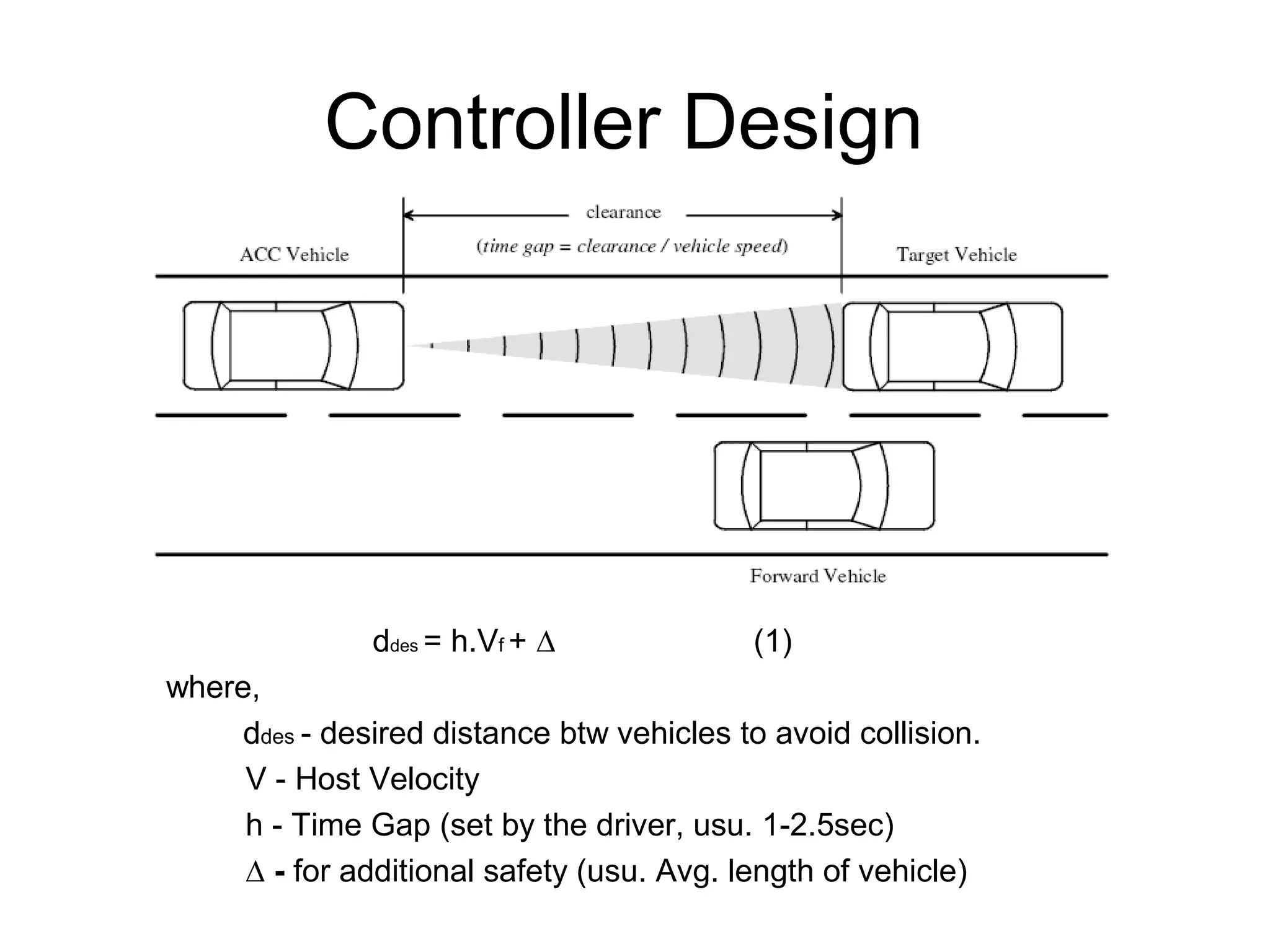

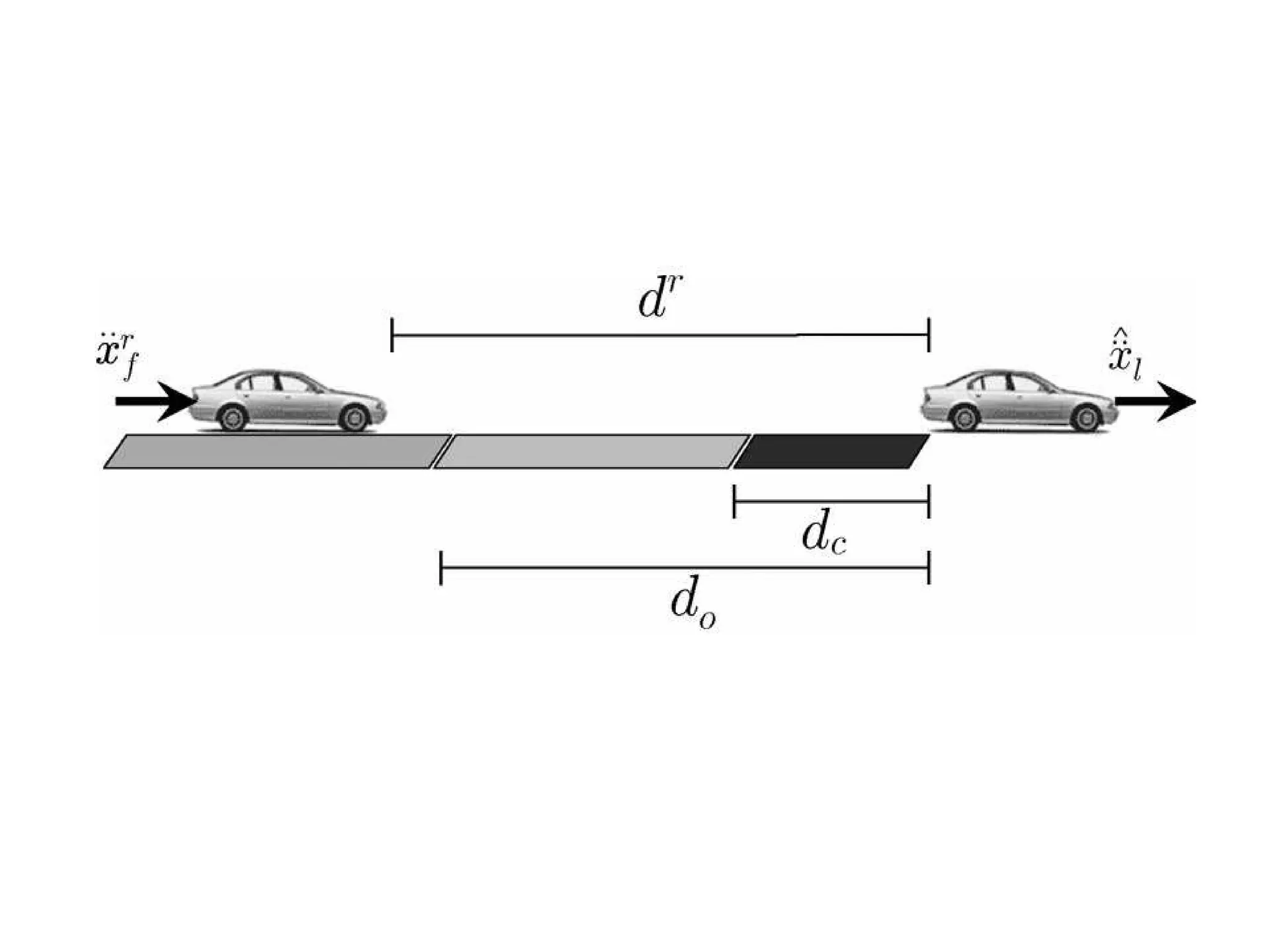

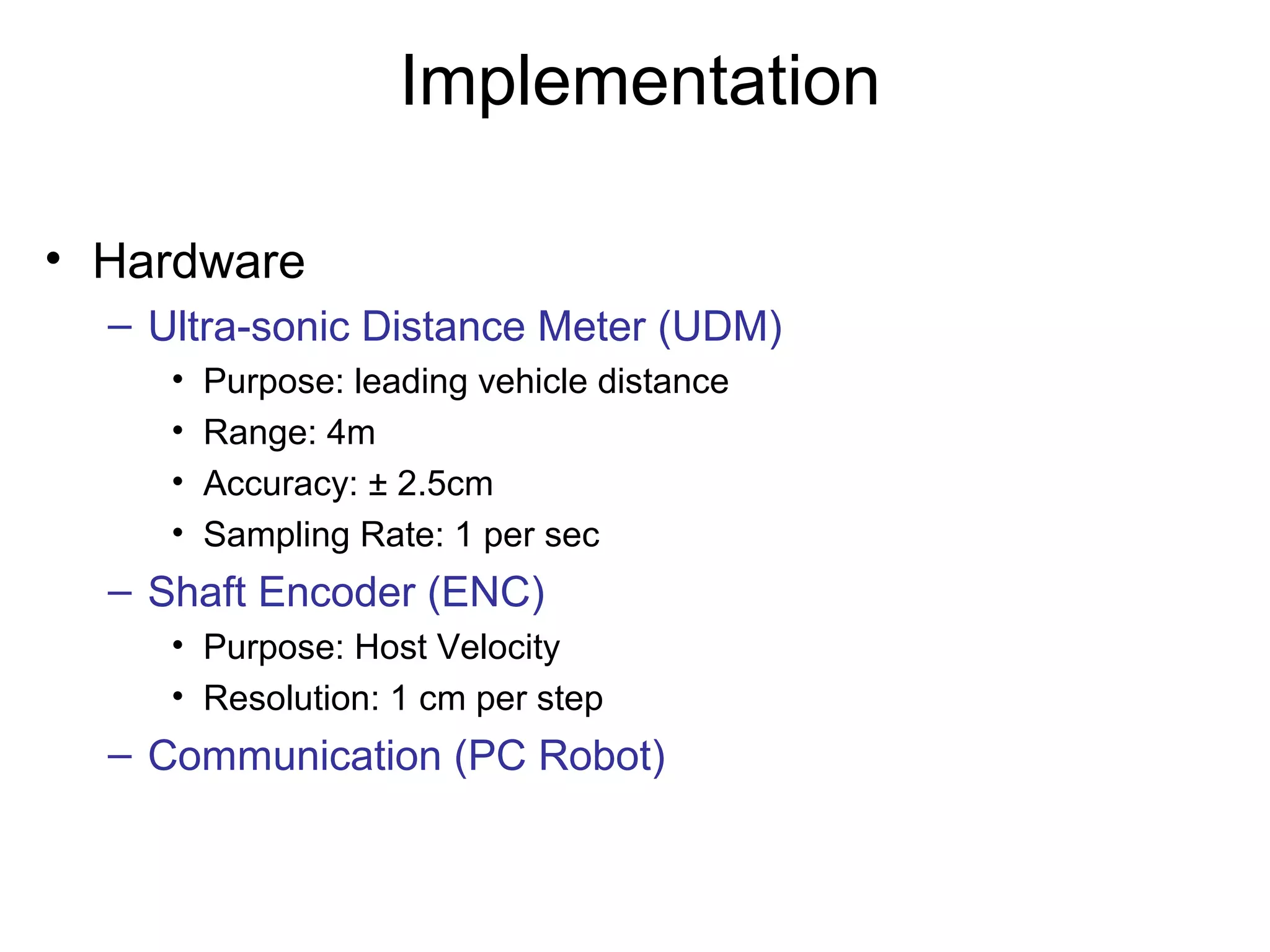

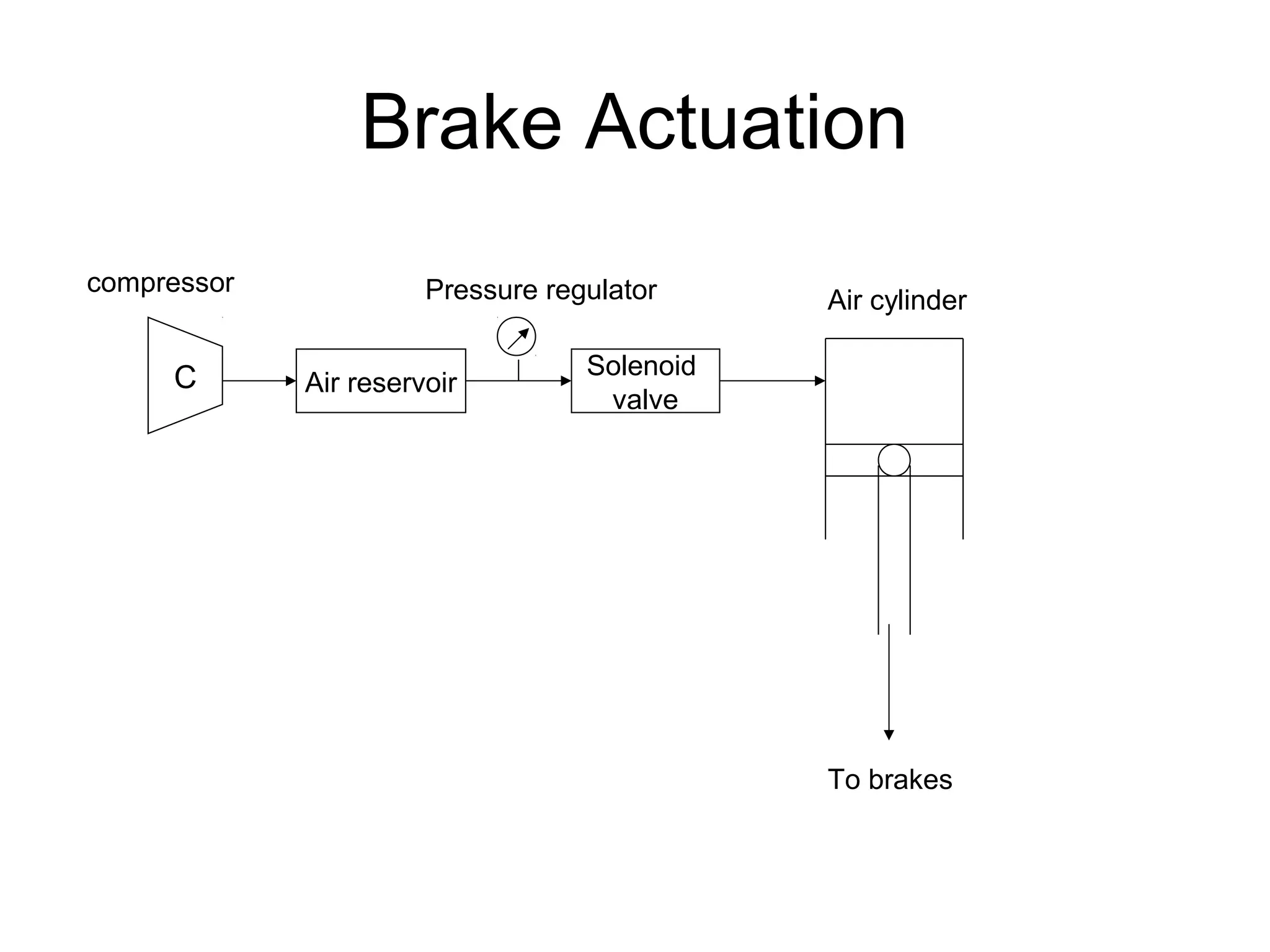

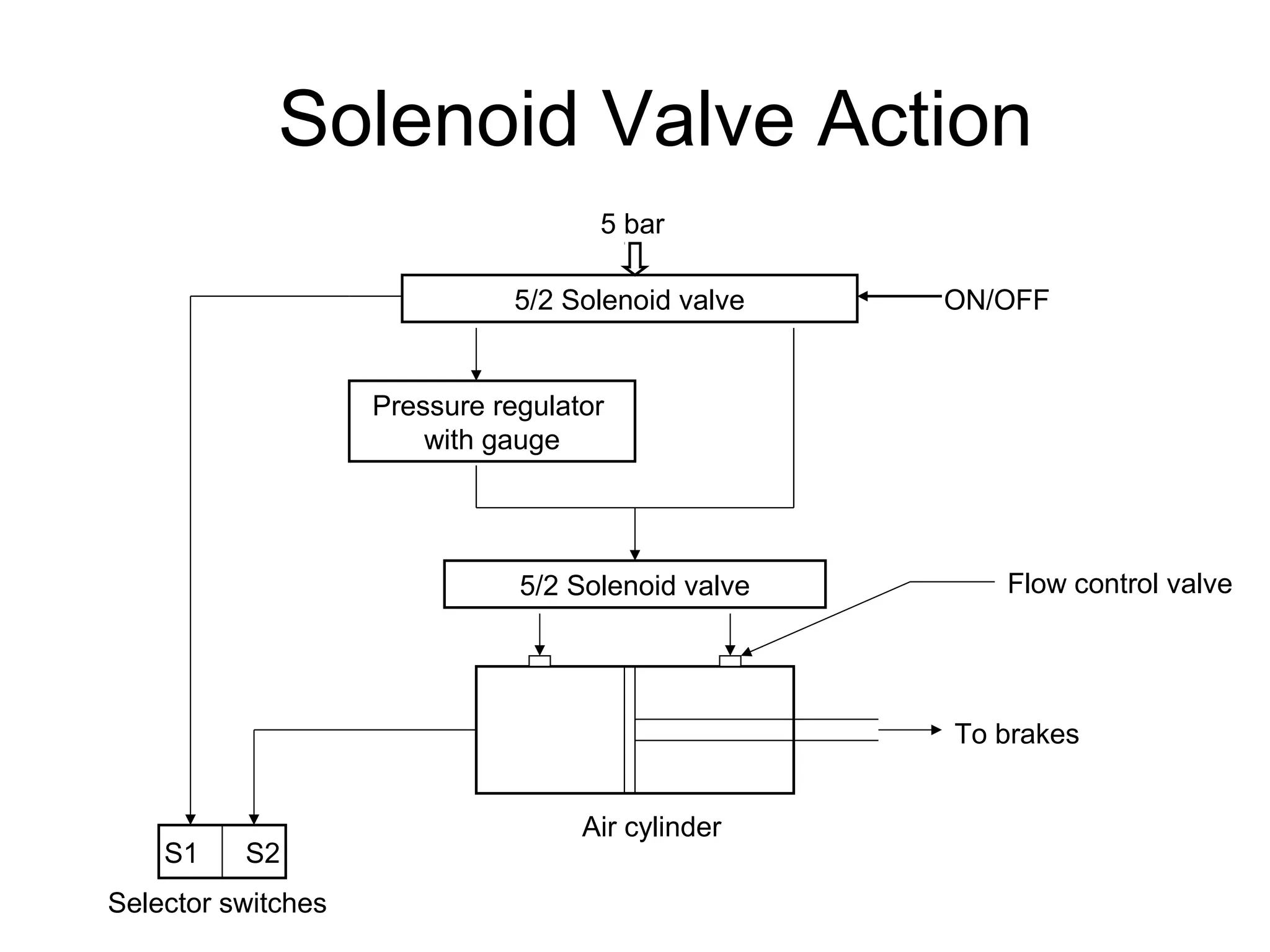

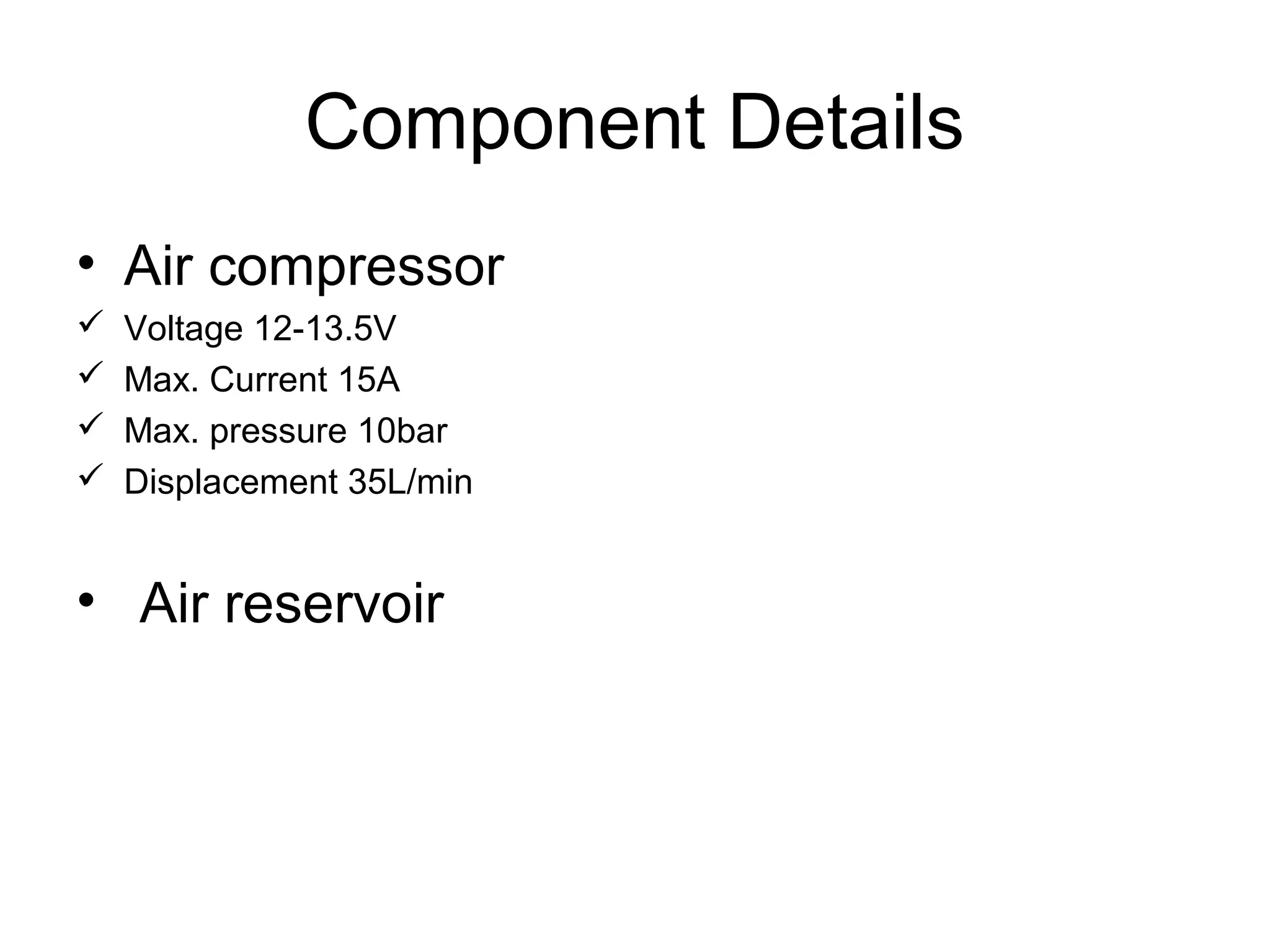

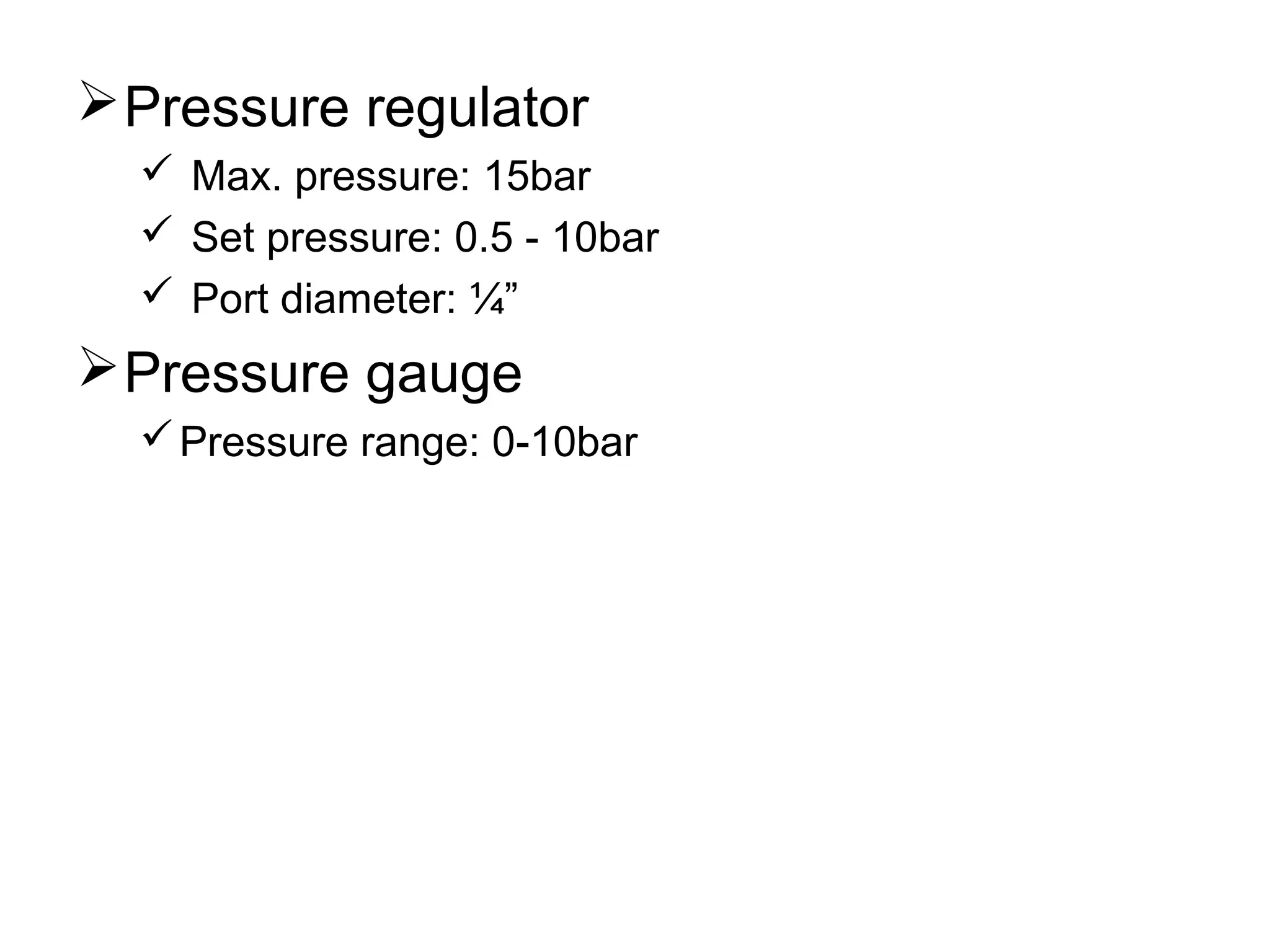

This document describes the modeling and implementation of an adaptive cruise control (ACC) system for vehicles. It discusses the components of ACC including radar sensors, a controller, actuators for braking and throttle control, and a user interface. It also covers modeling the ACC system using equations of motion and Laplace transforms. The document concludes by discussing hardware implementation of the braking system and potential future work such as additional testing and applications to other vehicle types.