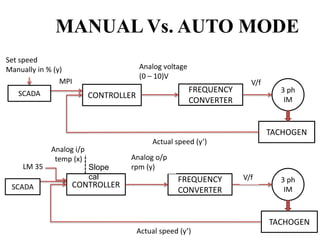

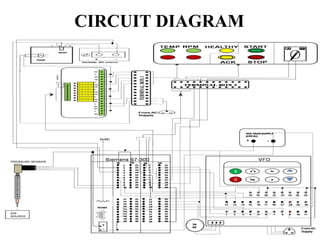

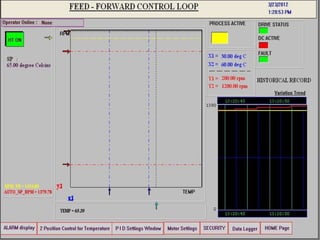

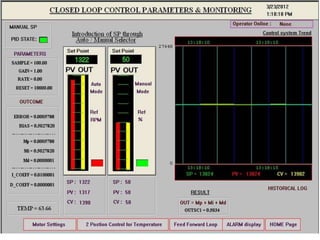

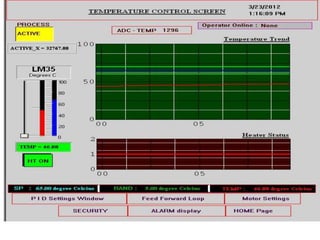

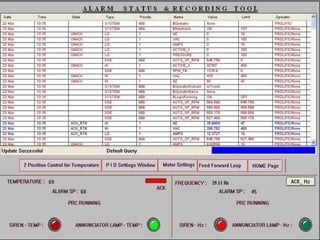

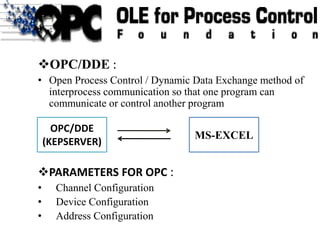

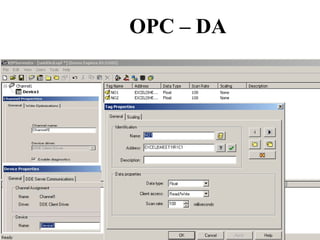

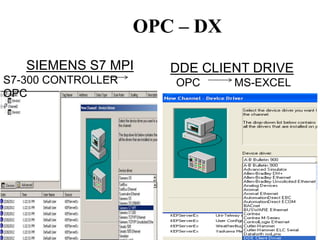

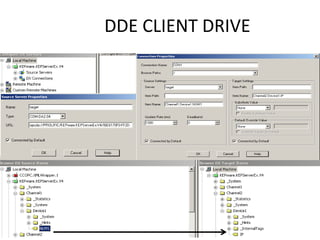

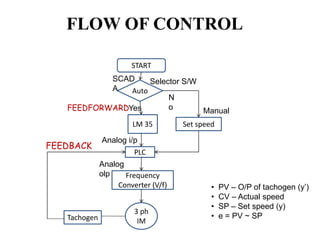

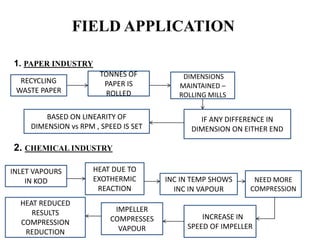

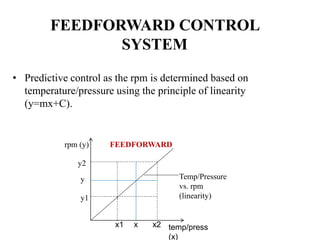

This document describes the development of a dynamic control system for industrial applications using a Siemens S7-300 PLC and various sensors. The system uses two-position control, feedforward control based on linear relationships between process variables, and feedback control using a PID algorithm. It allows both manual and automatic control modes. Data is exchanged between the PLC and SCADA software using OPC/DDE communication.

![• Variable speed is achieved using VFD that

generates variable frequency supply with constant

voltage to frequency ratio.[Performance range :

0.12 – 250KW]

MICROMASTER 440](https://image.slidesharecdn.com/4b232ed2-94a2-4608-9a3b-f212adccaeb2-161111051931/85/BATCH15-8-320.jpg)