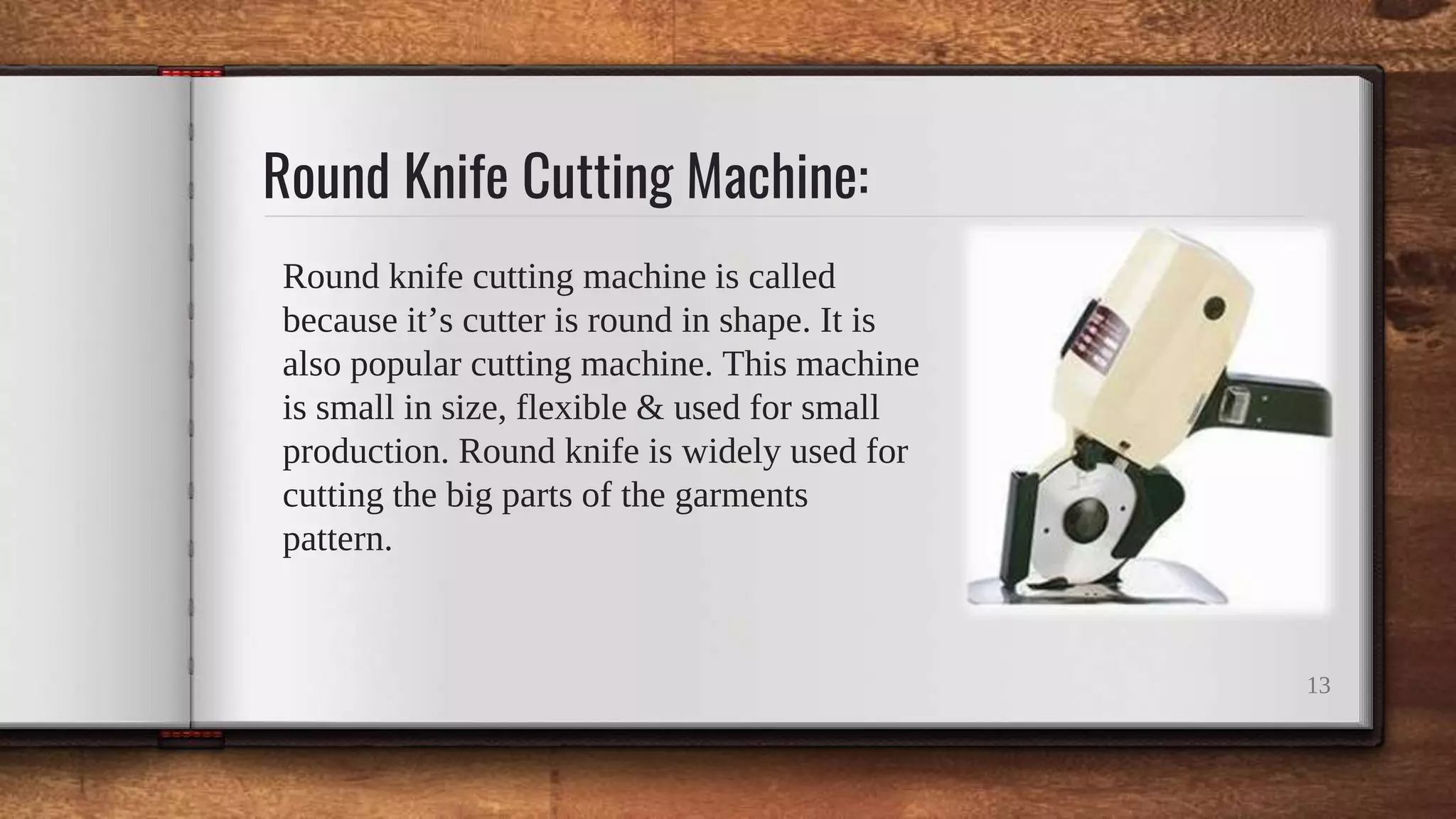

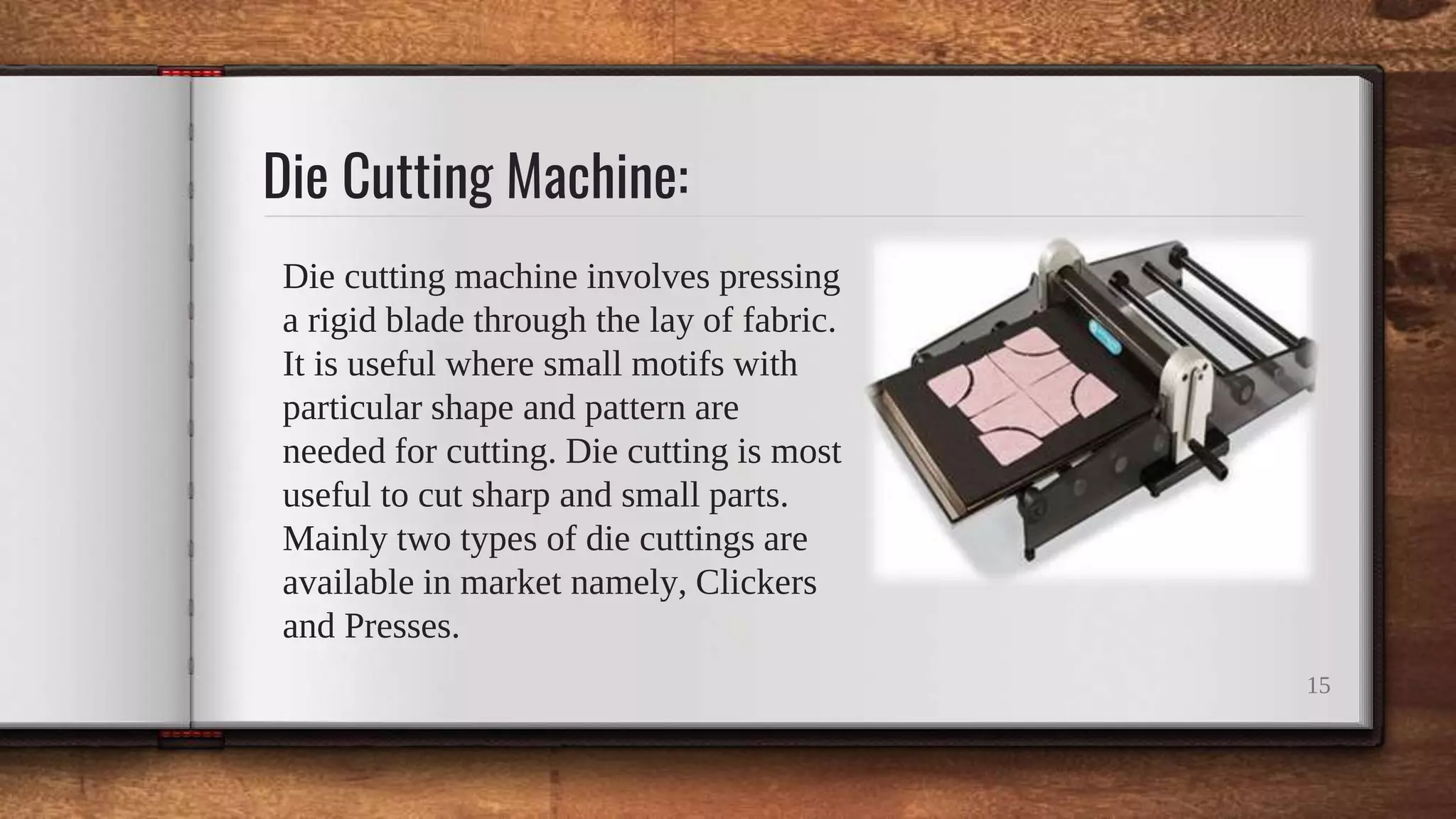

The document discusses fabric cutting methods in the garment manufacturing industry, highlighting manual and computerized techniques. The manual cutting method is affordable but slower and less efficient for large production, whereas the computerized method offers speed and precision but requires skilled labor and higher costs. Various machines used for cutting, like round knife, band knife, and laser cutting machines, are also described, showcasing their specific advantages and applications.