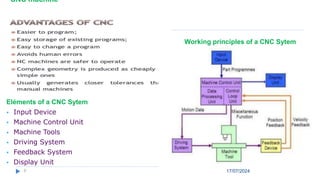

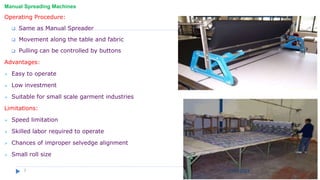

The document discusses how technology is transforming the fashion industry, emphasizing advancements such as automated sewing, AI trend prediction, and VR in retail. It covers various manufacturing processes including Computer Aided Manufacturing (CAM) and types of fabric spreading and cutting machines, highlighting their advantages and limitations. The integration of computerized sewing machines also plays a critical role in enhancing efficiency and accuracy within the industry.