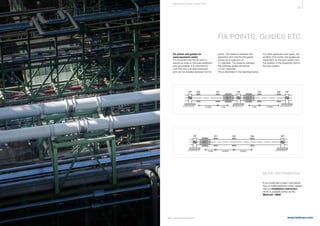

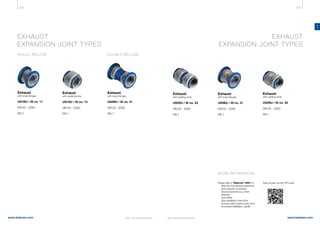

The Belman expansion joints catalogue provides comprehensive information on various types of metallic expansion joints, including their applications across industries, technical specifications, and design guidelines. The catalogue emphasizes the advantages of using expansion joints over alternatives such as pipe loops, highlighting cost-effectiveness, space savings, and reduced maintenance needs. Additionally, it offers access to customized solutions and technical support through the company's website.

![53

www.belman.comB022016-1 – Subject to alterations and eventual misprints

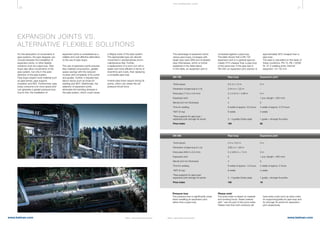

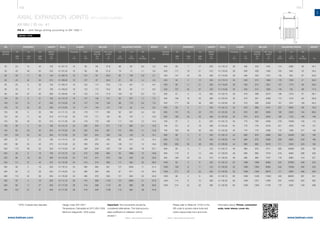

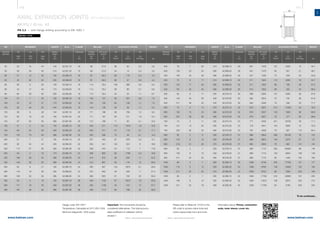

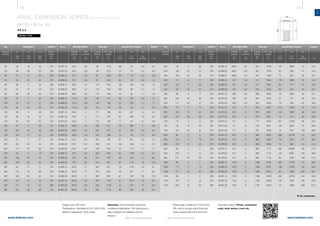

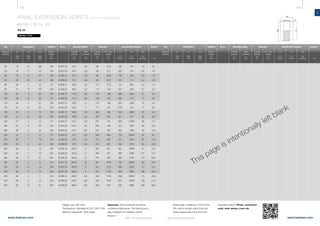

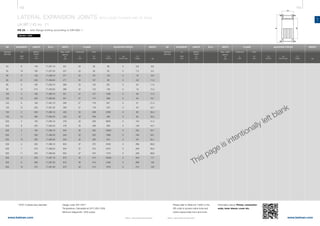

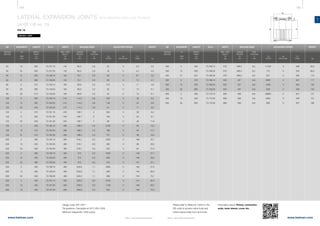

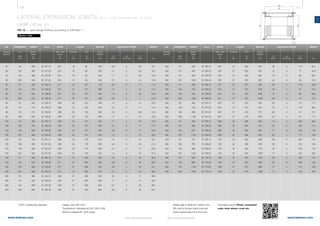

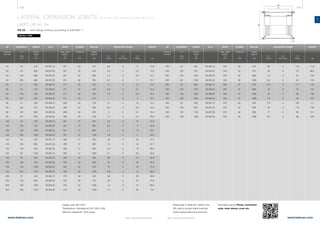

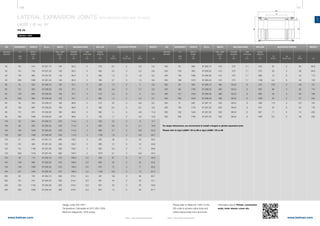

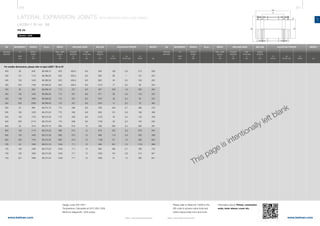

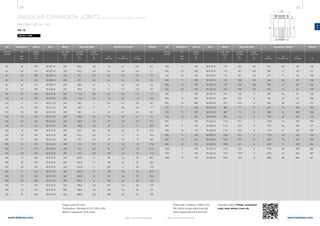

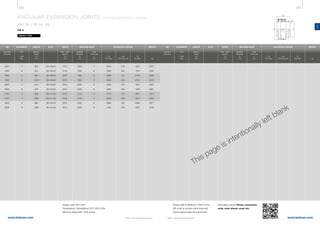

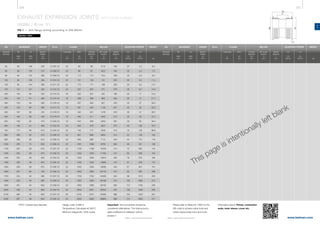

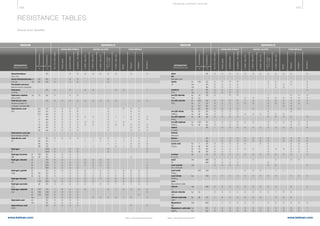

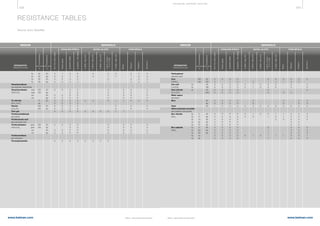

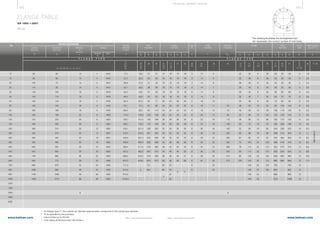

MATERIAL

Source: EN 14917:2009

TYPE

Number Steel name

TEMPERATURE °C

MaximumMinimum

DOCUMENT

a = Minimum temperature according to EN 13445-2/Annex B or EN 13480-2/Annex B.

b = Minimum temperature according to CERN [7].

c = Minimum temperature for cold-rolled strip up to 6 mm and hot rolled sheet up to 12 mm thickness [2].

d = Special care should be exercised due to the risk of embrittlement when using the materials at elevated temperatures above 550°C.

e = Minimum temperature is possible when the specified minimum impact energy (normally 27 J) can be proved.

MATE R I A LS

TEMPERATURE LIMITS

FOR BELLOW MATERIALS

1.4301 X5CrNi18-10 -196a

550

1.4306 X2CrNi19-11 -270a

550

1.4401 X5CrNiMo17-12-2 -196a

550

1.4404 X2CrNiMo17-12-2 -270b

550

1.4435 X2CrNiMo18-14-3 -270a

550

1.4539 X1CrNiMoCuN25-20-5 -196a

550

1.4541 X6CrNiTi18-10 -270c

550

1.4550 X6CrNiNb18-10 -196a

550

1.4571 X6CrNiMoTi17-12-2 -270c

550

1.4828 X15CrNiSi20-12 -196 900d

Annex B, Position 1

X10NiCrAITi32-21 -196 600 Annex B, Position 2.1

X10NiCrAITi32-21 (H) 900d

Annex B, Position 2.2

2.4610 NiMo16Cr16Ti -196 400 EAM-0526-28

EAM-0526-43-1,

2.4819 NiMo16Cr15W -196 400 EAM-0526-18

-196 450 EAM-0526-40

(-270) (900)d

([11], [12])

2.4360 NiCu30Fe -196 425 Annex B, Position 3

2.4858 NiCr21Mo -270 540 Annex B, Position 4

1.0345 P235GH -20 400

1.0425 P265GH -20 400

1.5415 16Mo3 -20e

500

1.7335 13CrMo4-5 -20e

500

1.0565 P355NH -20 400

1.8935 P460NH -20 400

Stainless

austenitic

steels

Heat

resistant

austenitic

steels

EN 10028-7:2007

Ferritic

steels

EN 10028-2:2009

EN 10028-3:2009

Nickel

alloys

1.4876

2.4816

2.4856 NiCr22Mo9Nb

NiCr15Fe

-10 450

(-270) (900)d

([9]. [10])

EAM-0526-43-2](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-29-320.jpg)

![96 97

www.belman.comwww.belman.com

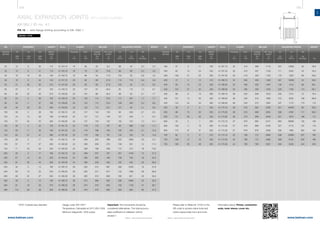

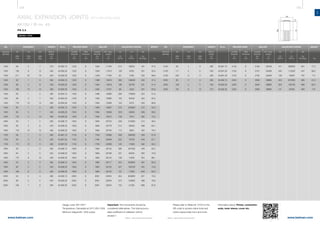

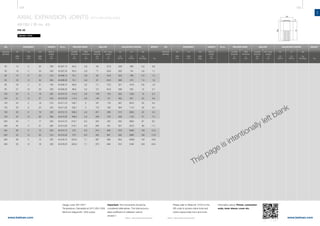

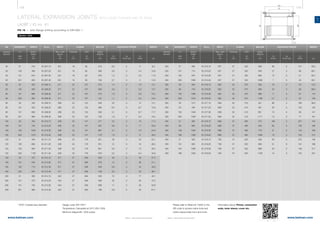

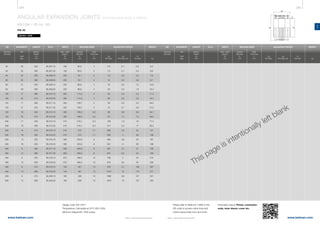

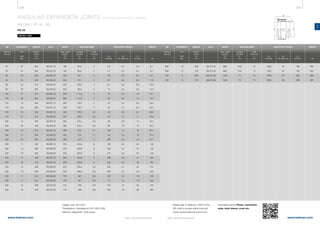

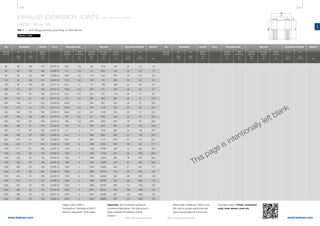

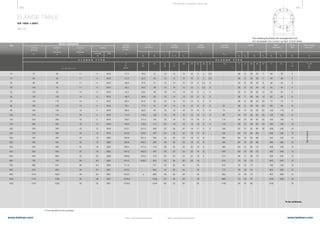

AX

B022016-1 – Subject to alterations and eventual misprintsB022016-1 – Subject to alterations and eventual misprints

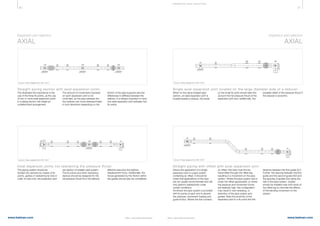

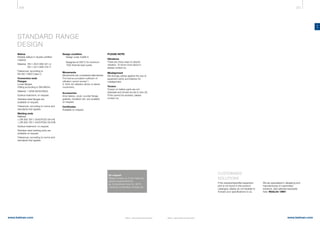

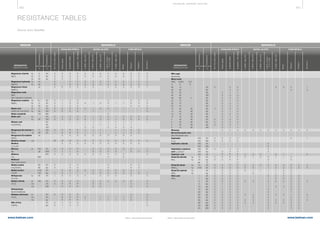

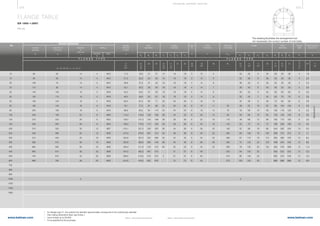

Design condition

l Design code: EN 14917

l Designed at 20°C for minimum

1000 thermal load cycles

l Arranged according nominal

pressure [PN]

l PN corresponds to the allowable

operating pressure at room

temperature [Rpt]

l Operating temperature from

-10°C to +400°C based on the

reduction factor (Kpa) from the

table on the next page

l All expansion joints are designed

to be tested at a pressure 1,43 x

the design pressure.

Where a higher test pressure is

required a unit with a higher

nominal pressure (PN) should be

selected to achieve this

Movements

Movements are considered alternatives.

The total accumulated coefficient of

utilisation cannot exceed 1.

A 100% AX utilisation allows no lateral

movements.

Bellow

Multiply bellow in double certified

material.

Material: EN 1.4541/AISI 321 or

EN 1.4571/AISI 316 Ti

Tolerances: according to

EN ISO 13920 Class C.

Connection ends

Flanges

Loose flanges, welded flanges.

Drilling according to EN 1092.

Material: 1.0460 (C 22.8) or

1.0425 P265 GH (HII)

Surface treatment: primer coated.

Stainless steel flanges are

available on request.

Tolerances: according to norms and

standards that applies.

Welding ends

Material:

≤ DN 500: EN 1.0345/P235 GH (HI)

> DN 500: EN 1.0425/P265 GH (HII)

Surface treatment: primer coated.

Stainless steel welding ends are

available on request.

Tolerances: according to norms and

standards that applies.

STANDARD RANGE

DESIGN

We are specialised in designing and

manufacturing of customised

solutions. See selected examples

here: WebLink 13601

If the required/specified expansion

joint is not found in this product

catalogue, please do not hesitate to

forward your specifications to us.

CUSTOMISED

SOLUTIONS

Accessories

Inner sleeve, cover, counter flange,

gaskets, insulation etc. are available

on request.

Certificates

Material certificate 3.1 according to

EN 10204 and/or ASME.

PLEASE NOTE!

Vibrations

There are many ways to absorb

vibration. To know more about it,

please contact us.

Misalignment

We strongly advise against the use of

expansion joints and bellows for

misalignment.

Torsion

Torsion on bellow parts are not

desirable and should be set to zero (0).

If this cannot be avoided, please

contact us.

TEMPERATURE

°C

REDUCTION FACTOR

Kpa

20 1,00

100 0,83

150 0,78

200 0,74

250 0,71

300 0,67

350 0,64

400 0,62

Pressure reduction factor

The factor used for reduction of

pressure [Kpa], is based on the bellow

material yield strength at design

temperature [Rp], and the yield

strength at room temperature [Rpt].

Definiton: Kpa = Rp / Rpt

The reduction factor is applied to

modify the design pressure [PS] where

temperatures exceed 20°C, it com-

pensates for the decay in material

mechanical properties at elevated

temperatures. The modified pressure

must always be lower than the nominal

pressure of the standard item.

Calculation: PS / Kpa ≤ PN

Where the applied design pressure

is lower than the nominal pressure

for the standard unit an increase in

fatigue life expectancy and / or

increased movements can be

achieved.

Please refer to Belmaker Light®

to get an optimised solution.

On request

Please contact us, if you have any

special requirements for

eg. temperature down to -60°C,

a special combination of ends etc.](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-51-320.jpg)

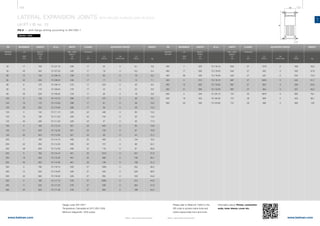

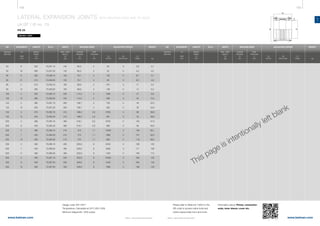

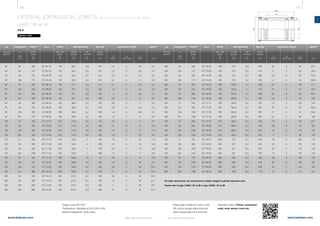

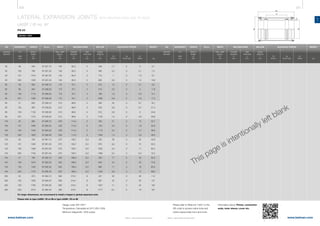

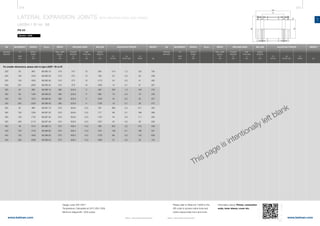

![144 145

www.belman.comwww.belman.com

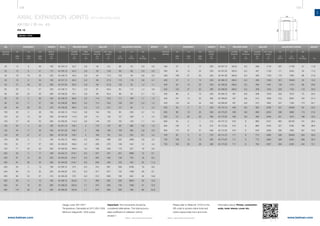

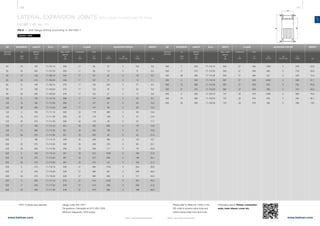

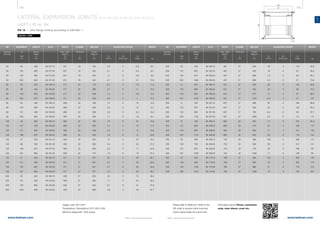

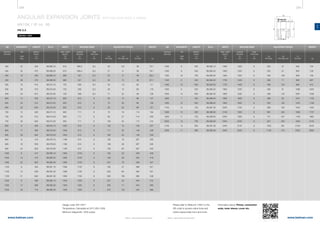

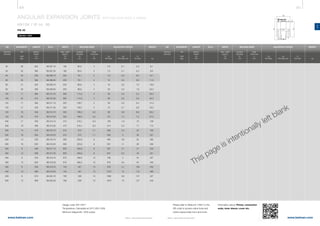

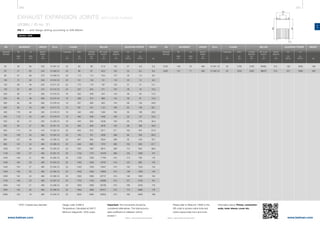

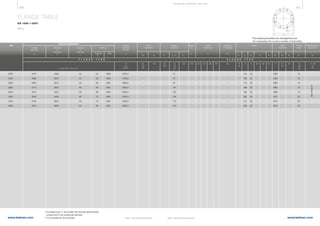

LA

B022016-1 – Subject to alterations and eventual misprintsB022016-1 – Subject to alterations and eventual misprints

On request

Please contact us, if you have any

special requirements for

eg. temperature down to -60°C,

a special combination of ends etc.

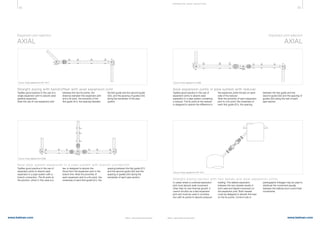

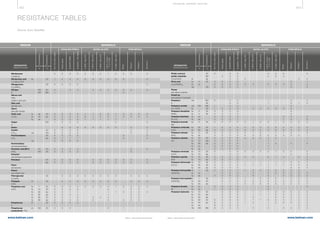

Design condition

l Design code: EN 14917

l Designed at 20°C for minimum

1000 thermal load cycles

l Arranged according nominal

pressure [PN]

l PN corresponds to the allowable

operating pressure at room

temperature [Rpt]

l Operating temperature from

-10°C to +400°C based on the

reduction factor (Kpa) from the

table on the next page

l All expansion joints are designed

to be tested at a pressure 1,43 x

the design pressure.

Where a higher test pressure is

required a unit with a higher

nominal pressure (PN) should be

selected to achieve this

Accessories

Inner sleeve, cover, counter flange,

gaskets, insulation etc. are available

on request.

Certificates

Material certificate 3.1 according to

EN 10204 and/or ASME.

Bellow

Multiply bellow in double certified

material.

Material: EN 1.4541/AISI 321 or

EN 1.4571/AISI 316 Ti

Tolerances: according to

EN ISO 13920 Class C.

Connection ends

Flanges

Loose flanges, welded flanges.

Drilling according to EN 1092.

Material: 1.0460 (C 22.8) or

1.0425 P265 GH (HII)

Surface treatment: primer coated.

Stainless steel flanges are

available on request.

Tolerances: according to norms and

standards that applies.

Welding ends

Material:

≤ DN 500: EN 1.0345/P235 GH (HI)

> DN 500: EN 1.0425/P265 GH (HII)

Surface treatment: primer coated.

Stainless steel welding ends are

available on request.

Tolerances: according to norms and

standards that applies.

Tie rods

Material: 1.7225 (42CrMo4)

The design of the tie rods and the

number of them are determined by

diameter and pressure.

Attachment plates and lugs

Material: EN 1.0425/P265 GH (HII)

STANDARD RANGE

DESIGN

We are specialised in designing and

manufacturing of customised

solutions. See selected examples

here: WebLink 13601

If the required/specified expansion

joint is not found in this product

catalogue, please do not hesitate to

forward your specifications to us.

CUSTOMISED

SOLUTIONS

PLEASE NOTE!

Vibrations

There are many ways to absorb

vibration. To know more about it,

please contact us.

Misalignment

We strongly advise against the use of

expansion joints and bellows for

misalignment.

Torsion

Torsion on bellow parts are not

desirable and should be set to zero (0).

If this cannot be avoided, please

contact us.

TEMPERATURE

°C

REDUCTION FACTOR

Kpa

20 1,00

100 0,83

150 0,78

200 0,74

250 0,71

300 0,67

350 0,64

400 0,62

Pressure reduction factor

The factor used for reduction of

pressure [Kpa], is based on the bellow

material yield strength at design

temperature [Rp], and the yield

strength at room temperature [Rpt].

Definiton: Kpa = Rp / Rpt

The reduction factor is applied to

modify the design pressure [PS] where

temperatures exceed 20°C, it com-

pensates for the decay in material

mechanical properties at elevated

temperatures.The modified pressure

must always be lower than the

nominal pressure of the standard item.

Calculation: PS / Kpa ≤ PN

Where the applied design pressure

is lower than the nominal pressure

for the standard unit an increase in

fatigue life expectancy and / or

increased movements can be

achieved.

Please refer to Belmaker Light®

to get an optimised solution.](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-75-320.jpg)

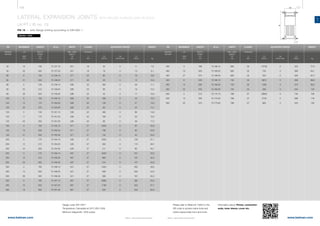

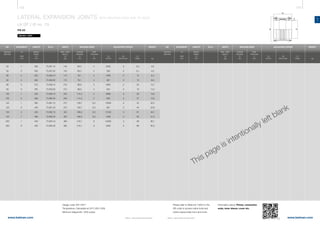

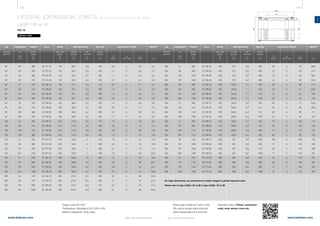

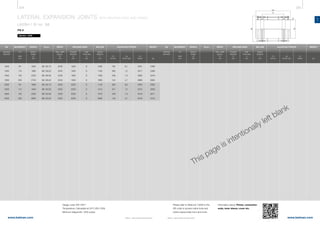

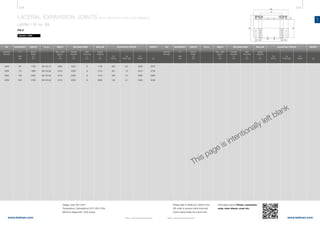

![238 239

www.belman.comwww.belman.com

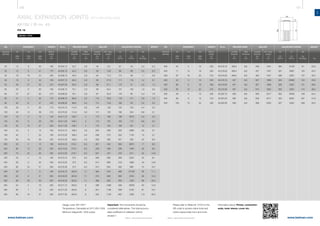

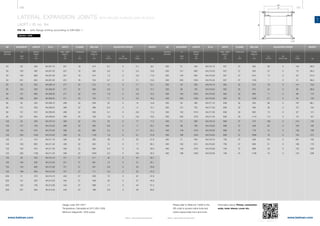

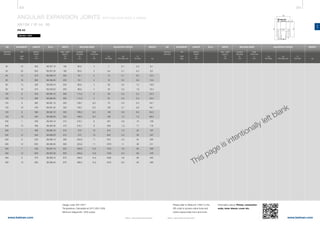

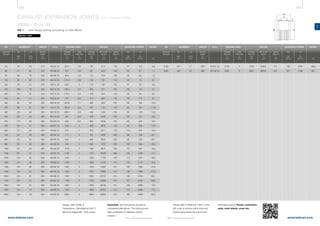

AN

B022016-1 – Subject to alterations and eventual misprintsB022016-1 – Subject to alterations and eventual misprints

On request

Please contact us, if you have any

special requirements for

eg. temperature down to -60°C,

a special combination of ends etc.

Design condition

l Design code: EN 14917

l Designed at 20°C for minimum

1000 thermal load cycles

l Arranged according nominal

pressure [PN]

l PN corresponds to the allowable

operating pressure at room

temperature [Rpt]

l Operating temperature from

-10°C to +400°C based on the

reduction factor (Kpa) from the

table on the next page

l All expansion joints are designed

to be tested at a pressure 1,43 x

the design pressure.

Where a higher test pressure is

required a unit with a higher

nominal pressure (PN) should be

selected to achieve this

Accessories

Inner sleeve, cover, counter flange,

gaskets, insulation etc. are available

on request.

Certificates

Material certificate 3.1 according to

EN 10204 and/or ASME.

Bellow

Multiply bellow in double certified

material.

Material: EN 1.4541/AISI 321 or

EN 1.4571/AISI 316 Ti

Tolerances: according to

EN ISO 13920 Class C.

Connection ends

Flanges

Loose flanges, welded flanges.

Drilling according to EN 1092.

Material: 1.0460 (C 22.8) or

1.0425 P265 GH (HII)

Surface treatment: primer coated.

Stainless steel flanges are

available on request.

Tolerances: according to norms and

standards that applies.

Welding ends

Material:

≤ DN 500: EN 1.0345/P235 GH (HI)

> DN 500: EN 1.0425/P265 GH (HII)

Surface treatment: primer coated.

Stainless steel welding ends are

available on request.

Tolerances: according to norms and

standards that applies.

Attachment plates/hinges/gimbals

Material: EN 1.0425/P265 GH (HII)

STANDARD RANGE

DESIGN

We are specialised in designing and

manufacturing of customised

solutions. See selected examples

here: WebLink 13601

If the required/specified expansion

joint is not found in this product

catalogue, please do not hesitate to

forward your specifications to us.

CUSTOMISED

SOLUTIONS

PLEASE NOTE!

Vibrations

There are many ways to absorb

vibration. To know more about it,

please contact us.

Misalignment

We strongly advise against the use of

expansion joints and bellows for

misalignment.

Torsion

Torsion on bellow parts are not

desirable and should be set to zero (0).

If this cannot be avoided, please

contact us.

TEMPERATURE

°C

REDUCTION FACTOR

Kpa

20 1,00

100 0,83

150 0,78

200 0,74

250 0,71

300 0,67

350 0,64

400 0,62

Pressure reduction factor

The factor used for reduction of

pressure [Kpa], is based on the bellow

material yield strength at design

temperature [Rp], and the yield

strength at room temperature [Rpt].

Definiton: Kpa = Rp / Rpt

The reduction factor is applied to

modify the design pressure [PS] where

temperatures exceed 20°C, it com-

pensates for the decay in material

mechanical properties at elevated

temperatures. The modified pressure

must always be lower than the nominal

pressure of the standard item.

Calculation: PS / Kpa ≤ PN

Where the applied design pressure

is lower than the nominal pressure

for the standard unit an increase in

fatigue life expectancy and / or

increased movements can be

achieved.

Please refer to Belmaker Light®

to get an optimised solution.](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-122-320.jpg)

![310 311

www.belman.comwww.belman.com

UN

B022016-1 – Subject to alterations and eventual misprintsB022016-1 – Subject to alterations and eventual misprints

On request

Please contact us, if you have any

special requirements for

eg. temperature down to -60°C,

a special combination of ends etc.

Design condition

l Design code: EN 14917

l Designed at 20°C for minimum

1000 thermal load cycles

l Arranged according nominal

pressure [PN]

l PN corresponds to the allowable

operating pressure at room

temperature [Rpt]

l Operating temperature from

-10°C to +400°C based on the

reduction factor (Kpa) from the

table on the next page

l All expansion joints are designed

to be tested at a pressure 1,43 x

the design pressure.

Where a higher test pressure is

required a unit with a higher

nominal pressure (PN) should be

selected to achieve this

Movements

Movements are considered alternatives.

The total accumulated coefficient of

utilisation cannot exceed 1.

A 100% AX utilisation allows no lateral

movements.

Bellow

Multiply bellow in double certified

material.

Material: EN 1.4541/AISI 321 or

EN 1.4571/AISI 316 Ti

Tolerances: according to

EN ISO 13920 Class C.

Connection ends

Flanges

Loose flanges, welded flanges.

Drilling according to EN 1092.

Material: 1.0460 (C 22.8) or

1.0425 P265 GH (HII)

Surface treatment: primer coated.

Stainless steel flanges are

available on request.

Tolerances: according to norms and

standards that applies.

Welding ends

Material:

≤ DN 500: EN 1.0345/P235 GH (HI)

> DN 500: EN 1.0425/P265 GH (HII)

Surface treatment: primer coated.

Stainless steel welding ends are

available on request.

Tolerances: according to norms and

standards that applies.

STANDARD RANGE

DESIGN

We are specialised in designing and

manufacturing of customised

solutions. See selected examples

here: WebLink 13601

If the required/specified expansion

joint is not found in this product

catalogue, please do not hesitate to

forward your specifications to us.

CUSTOMISED

SOLUTIONS

Accessories

Inner sleeve, cover, counter flange,

gaskets, insulation etc. are available

on request.

Certificates

Material certificate 3.1 according to

EN 10204 and/or ASME.

PLEASE NOTE!

Vibrations

There are many ways to absorb

vibration. To know more about it,

please contact us.

Misalignment

We strongly advise against the use of

expansion joints and bellows for

misalignment.

Torsion

Torsion on bellow parts are not

desirable and should be set to zero (0).

If this cannot be avoided, please

contact us.

TEMPERATURE

°C

REDUCTION FACTOR

Kpa

20 1,00

100 0,83

150 0,78

200 0,74

250 0,71

300 0,67

350 0,64

400 0,62

Pressure reduction factor

The factor used for reduction of

pressure [Kpa], is based on the bellow

material yield strength at design

temperature [Rp], and the yield

strength at room temperature [Rpt].

Definiton: Kpa = Rp / Rpt

The reduction factor is applied to

modify the design pressure [PS] where

temperatures exceed 20°C, it com-

pensates for the decay in material

mechanical properties at elevated

temperatures. The modified pressure

must always be lower than the nominal

pressure of the standard item.

Calculation: PS / Kpa ≤ PN

Where the applied design pressure

is lower than the nominal pressure

for the standard unit an increase in

fatigue life expectancy and / or

increased movements can be

achieved.

Please refer to Belmaker Light®

to get an optimised solution.](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-158-320.jpg)

![350 351

www.belman.comwww.belman.com

VA

B022016-1 – Subject to alterations and eventual misprintsB022016-1 – Subject to alterations and eventual misprints

On request

Please contact us, if you have any

special requirements for

eg. temperature down to -60°C,

a special combination of ends etc.

Design condition

l Design code: EN 14917

l Designed at 20°C for minimum

1000 thermal load cycles (2λN) and

vibrations (+/- 0,5 mm in all

planes).

l Arranged according nominal

pressure [PN]

l PN corresponds to the allowable

operating pressure at room

temperature [Rpt]

l Operating temperature from

-10°C to +400°C based on the

reduction factor (Kpa) from the

table on the next page

l All expansion joints are designed

to be tested at a pressure 1,43 x

the design pressure.

Where a higher test pressure is

required a unit with a higher

nominal pressure (PN) should be

selected to achieve this

Bellow

Multiply bellow in double certified

material.

Material: EN 1.4541/AISI 321 or

EN 1.4571/AISI 316 Ti

Tolerances: according to

EN ISO 13920 Class C.

Connection ends

Flanges

Welded flanges.

Drilling according to EN 1092.

Material: 1.0460 (C 22.8) or

1.0425 P265 GH (HII)

Surface treatment: primer coated.

Stainless steel flanges are

available on request.

Tolerances: according to norms and

standards that applies.

Tie rods

Material: 1.7225 (42CrMo4)

The design of the tie rods and the

number of them are determined by

diameter and pressure.

Rubber bushes: NBR (to max. 120ºC,

at higher temperatures metallic

springs are used).

STANDARD RANGE

DESIGN

We are specialised in designing and

manufacturing of customised

solutions. See selected examples

here: WebLink 13601

If the required/specified expansion

joint is not found in this product

catalogue, please do not hesitate to

forward your specifications to us.

CUSTOMISED

SOLUTIONS

Accessories

Inner sleeve, cover, counter flange,

gaskets, insulation etc. are available

on request.

Certificates

Material certificate 3.1 according to

EN 10204 and/or ASME.

PLEASE NOTE!

Natural frequencies

To avoid resonant response, following

relation between the bellows natural

frequency (fn) and system frequency

(fs) must be fulfilled:

fn < 2/3 x fs

or

fn > 2 x fs

Misalignment

We strongly advise against the use of

expansion joints and bellows for

misalignment.

Torsion

Torsion on bellow parts are not

desirable and should be set to zero (0).

If this cannot be avoided, please

contact us.

TEMPERATURE

°C

REDUCTION FACTOR

Kpa

20 1,00

100 0,83

150 0,78

200 0,74

250 0,71

300 0,67

350 0,64

400 0,62

Pressure reduction factor

The factor used for reduction of

pressure [Kpa], is based on the bellow

material yield strength at design

temperature [Rp], and the yield

strength at room temperature [Rpt].

Definiton: Kpa = Rp / Rpt

The reduction factor is applied to

modify the design pressure [PS] where

temperatures exceed 20°C, it com-

pensates for the decay in material

mechanical properties at elevated

temperatures. The modified pressure

must always be lower than the nominal

pressure of the standard item.

Calculation: PS / Kpa ≤ PN

Where the applied design pressure

is lower than the nominal pressure

for the standard unit an increase in

fatigue life expectancy and / or

increased movements can be

achieved.

Please refer to Belmaker Light®

to get an optimised solution.](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-178-320.jpg)

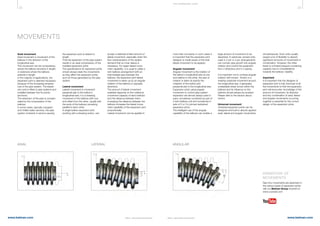

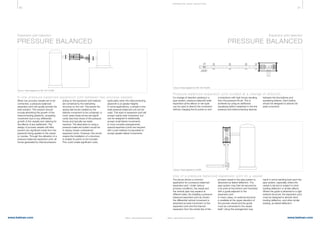

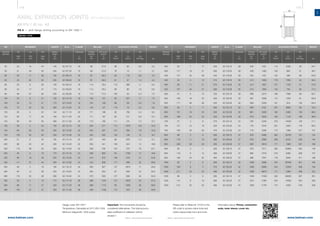

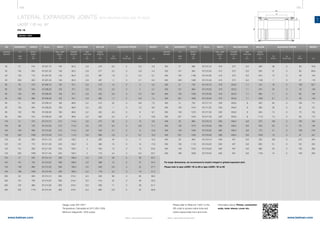

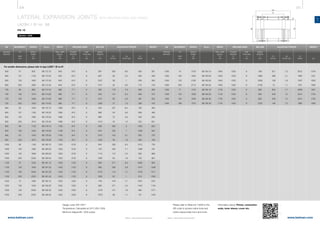

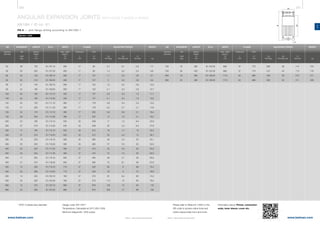

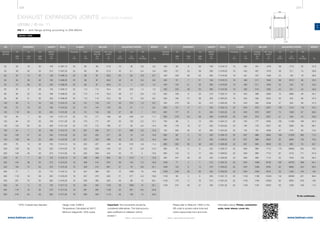

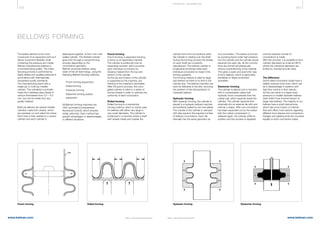

![414 415

www.belman.comwww.belman.com B022016-1 – Subject to alterations and eventual misprintsB022016-1 – Subject to alterations and eventual misprints

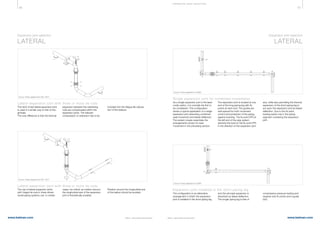

TE CHNI CA L I NFOR MATI ON

PRESSURE THRUST

Force in a perpendicular direction or

applied normally on an area is called

thrust. Pressure thrust force is the

most essential force encountered in

pressurised pipe systems and if

ignored or incorrectly calculated, it

can have a major impact on the pipe

system or the surrounding hardware.

Expansion joints are intended to

absorb pipe expansion and to

withstand pressure forces and

movements. However unrestrained

expansion joints also transfer forces,

where the most important factors are

the bellows spring rate and pressure

thrust. Pressure thrust force acts

Fp = P x A

Where:

Fp = Pressure thrust force [N]

P = Pressure [bar]

A = Bellows mean diameter

area [mm2

]

Unrestrained

With unrestrained expansion joints,

both spring rates and pressure thrust

forces occur, and the pressure thrust

is often greater than the spring rates.

This type of expansion joint always

requires fix points or a foundation,

which is rigid enough to carry the

differently depending on whether the

pipe system is anchored and guided

or floating. If unrestrained axial

expansion joints are used, pressure

thrust force must be obtained at both

ends of the pipe system by fix points.

Single bellows subjected to an axial

movement could be simplified as an

hydraulic cylinder with a spring inside.

The spring represents the axial spring

rate of the bellows, and the hydraulic

piston represents the effect of the

pressure thrust which the expansion

joint can exert on the piping fix points

or pressure thrust restraints.

The area of the hydraulic cylinder

loads. This often results in a high

financial cost.

Restrained

Alternatively, the reaction force from

the bellows can be eliminated by

using restrained expansion joints.

Restrained expansion joints are

restrained by using tie-rods, hinge- or

gimbal systems over the flexible part.

This hardware obtains all pressure

thrust forces and makes the

expansion joint behave like a straight

pipe, the only load to consider is the

spring rate.

Restrained expansion joints can be a

very cost effective solution in many

would be effective area of the bellows.

Expansion joints normally have a

cross-sectional area, which is slightly

larger than the pipe diameter due to the

height of the convolutions. This is a

critical detail to take into consideration

when designing pipe systems and fix

points. The effective cross section can

be illustrated by the sketch below.

Pressure thrust force is calculated by

the product of the bellows mean

diameter multiplied by the maximum

line pressure as follows:

(always base the calculation on the

maximum pressure that occurs, usually

the test pressure)

situations, where costly fix points and

foundation work is required.

Pressure balanced

Where large diameters, high pressure,

or fix points are impractical due to

economic or structural reasons, a

pressure balanced expansion joint

can be a powerful solution to a

challenging design problem.

This type of expansion joint is

basically the same as a restrained

unit, but in which the pressure thrust

is compensated by larger balancing

bellows or a balancing chamber.

Bellowsmeandiameter

P

Bellows effective area

P P

Fp Fp

Bellows spring rate

Hydraulic pistonCompensator pipe end

Compensator pipe end

Hydraulic cylinder

Bellows

Bellowsmeandiameter

Bellows pressure thrustBellows pressure thrust](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-210-320.jpg)

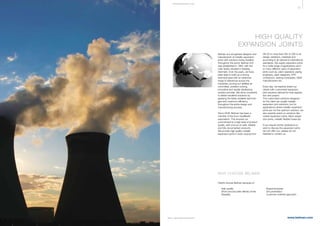

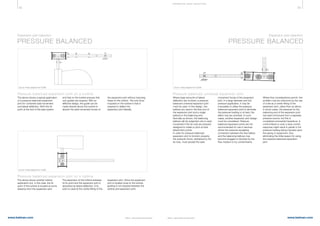

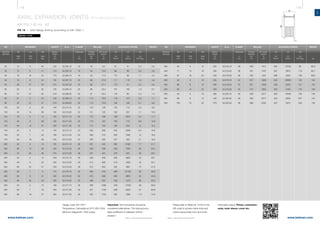

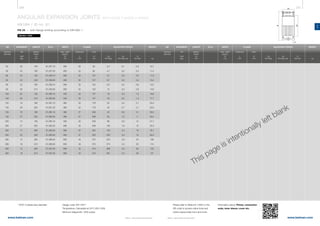

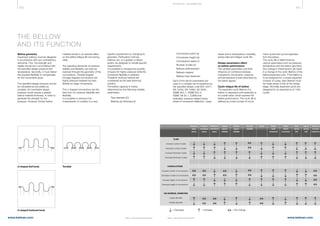

![416 417

www.belman.comwww.belman.com

Δx

X

F

K

B022016-1 – Subject to alterations and eventual misprintsB022016-1 – Subject to alterations and eventual misprints

SPRING RATES

Flexible bellows can be compared to

a steel spring in its flexible motion.

The spring rate is an expression of the

force required to compress or extend

the bellows, or alternately its

resistance to deflect, which is another

factor to take into account when

calculating loads on fix points.

The bellows spring rate depends

particularly on the bellows geometry

and especially the bellows ply

thickness, the number of plies,

convolution geometry and materials.

Secondly, the actual working

temperature of the bellows also

influences the spring rate, as the steel

loses its rigidity at elevated tempera-

tures. Therefore, the specified design

temperature should be as close to the

maximum as possible, without being

overstated.

The magnitude of the spring force is

determined by the expansion joint

spring constant and the amount of

movement of the expansion joint,

which is calculated as follows:

F = K x X

Where:

F = Force [N]

K = Spring rate [N/mm]

X = Movement [mm]

The bellows will have a spring back

effect when the movement range is

within the elastic range of the

material. But an excessive movement

range will result in a permanent

deformation of the bellows, especially

when the movement range is entering

into the plastic range of the bellows

material.

Belman specifies spring rates

calculated in full in accordance with

the specified code. The majority of

tests have verified actual spring rates

to have been around 30% less than

calculated. When a particular

application requires a more precise

specification of the bellows working

spring rate, the customer should

specify this to Belman. In special

projects, Belman will determine if a

prototype testing is necessary to

specify the precise load vs. deflection

characteristics of a particular bellows

design.

STABILITY

Expansion joints have to be flexible to

absorb movements but at the same

time they require the strength and

stability to transfer any specified fluid

at a given pressure and temperature.

In case an expansion joint is exposed

to an excessive internal pressure, the

bellows will show instability. Instability

can occur in two modes, column

instability or in-plane deformation

(squirm) of the convolution side wall.

Column instability applies only to

bellows with internal pressure.

Column instability (or squirm) is the

phenomena whereby the centerline of

a straight bellows develops a side-

ways or lateral bow. Column instability

affects the bellows as a whole, while

in-plane or squirm deformation affects

only one or more convolutions

individually. In-plane instability, called

also local instability or squirm, occurs

in bellows with relative small ratio of

length and diameter, and is defined as

slipping or twisting the plane of one or

several convolutions against each

parallel convolution.

The critical pressure at which this

instability occurs is a direct function of

the diameter and spring rate, and an

inverse function of the length.

A simple way to imagine this, is to

remember that the bellow is a cylinder

of given volume. Internal pressure

tries to increase a vessel’s volume.

Since a bellow is flexible in the axial

direction, it can increase its volume by

increasing the length of its centerline.

With the ends fixed, it tries so by

simulating the appearance of a

buckling column.

Column instability In-plane instability

TE CHNI CA L I NFOR MATI ON](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-211-320.jpg)

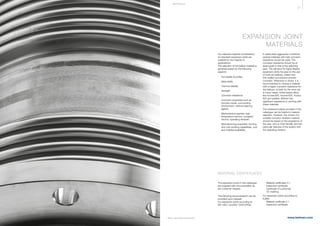

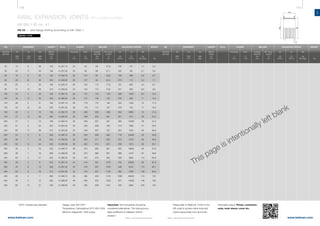

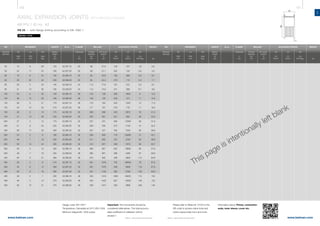

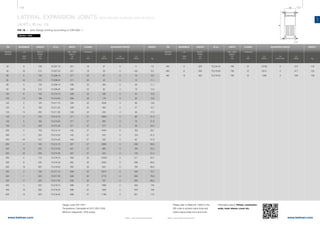

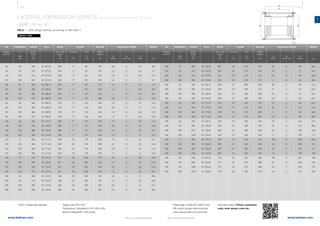

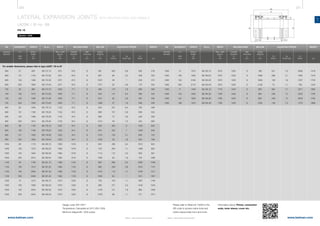

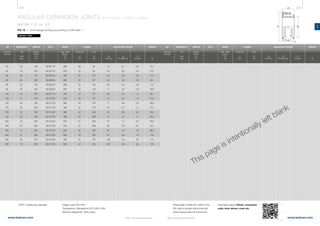

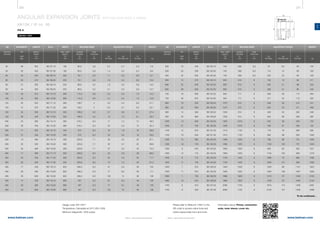

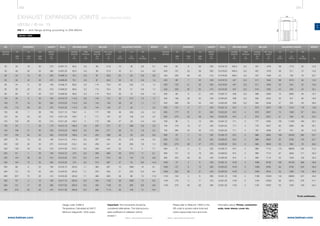

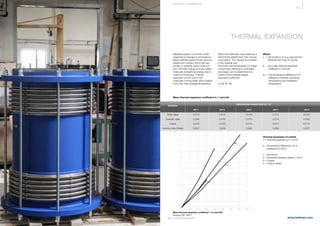

![480 481

www.belman.comwww.belman.com B022016-1 – Subject to alterations and eventual misprintsB022016-1 – Subject to alterations and eventual misprints

10 mm

thickness,

transverse min.

KV in J

min. KV

J

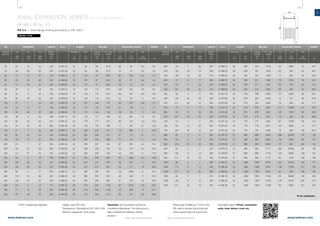

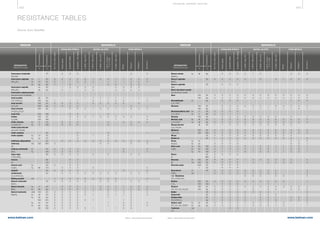

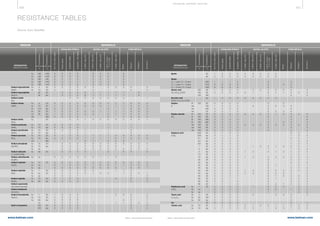

NON-ALLOYED

COMMON

STRUCTURAL STEEL

HEAT RESISTANT

NON-ALLOYED

HEAT RESISTANT

STEEL

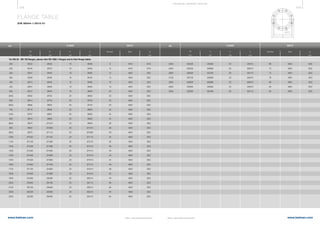

MATERIALS

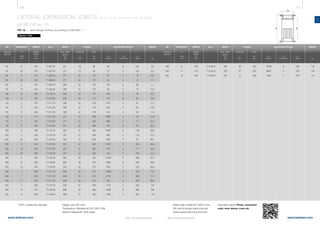

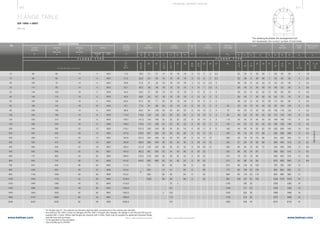

DESIGNATIONS, TEMPERATURES, STRENGTH VALUES

AT ROOM TEMPERATURE (R PT) , ETC.

Source: Is given in the table.

MATERIAL GROUP MATERIAL DESIGNATION TYPE DOCUMENTATION

Material no.

according to

DIN EN 10027

Common known

short name

Short name

according to

DIN EN 10027

min. Av

, (KV4)

)

J

TEMPERATURE

Upper limit

o

C

Yield point min.

Tensile strength

Rm

N/mm2

STRENGTH VALUES

A5

%

A80

%

1.0254

1.0255

1.0427

1.0038

1.0050

1.0570

1.0460

1.0345

1.0425

1.0481

1.5415

1.7335

1.7380

1.0305

P235TR1

P235TR2

C22G1

S235JRG2

E295

S355J2G3

C22G2

P235GH

P265GH

P295GH

16Mo3

13CrMo4-5

10CrMo9-10

P235G1TH

St. 37.0

St. 37.4

C 22.3

RSt 37-2

St 50-2

St 52-3

C 22.8

HI

HII

17 Mn 4

15 Mo 3

13 CrMo 4 4

10 CrMo 9 10

St. 35.8

DIN EN 10217-1

DIN EN 10216-1

DIN EN 10217-1

DIN EN 10216-1

VdTÜV-W 364

DIN EN 10025

ADW1

VdTÜVW 350

DIN EN 10028

DIN EN 10216

DIN EN 10028

DIN EN 10028

DIN 17175

DIN EN 10028

DIN 17175

DIN EN 10028

DIN 17175

DIN EN 10028

DIN 17175

DIN 17175

300

350

300

450

480

450

480

500

530

570

600

480

235

235

240

235

295

355

240

235

235

265

295

270

275

270

300

290

310

280

235

360-500

360-500

410-540

340-470

470-610

490-630

410-540

360-480

360-500

410-530

460-580

440-590

440-600

480-630

360-480

23

23

20 (transverse)

21-26 1)

16-20 1)

18-22 1)

20

25

23

23

22

24

20

18

23

17-21 3)

12-16 3)

14-18 )

at 0°C: 27

at RPT: 31

at RPT: 27

at -20°C: 27

at RPT:31

at 0°C: 27

at 0°C: 27

at 0°C: 27

at 0°C: 27

at RPT:31

at RPT:31

at RPT:31

at RPT:34

Welded pipe

Seamless pipe

Welded pipe

Seamless pipe

Flanges

Steel bar, flat products,

wire rod

profiles

Flanges

Sheet

Seamless pipe

Sheet

Sheet

Seamless pipe

Sheet

Seamless pipe

Sheet

Seamless pipe

Sheet

Seamless pipe

Seamless pipe

Elongation after fraction min.

ReH

N/mm2

Rp0,2

N/mm2

Rp1,0

N/mm2

Notched bar impact strength

1) Cold resistant limit

2) Smallest value of longitudinal or

transverse test

3) Dependent on product thickness

4) New designation to DIN EN 10045;

average of 3 specimens in DIN EN standards

5) Temperature limit with risk of

intercrystalline corrosion

6) Smallest value of longitudinal or trans-

verse test, q= tensile test, transverse,

I = Tensile test, longitudinal

7) Chemical composition

s ≤ 16

s ≤ 16

s ≤ 70

3 ≤ s ≤100 (Rm

)

10 ≤ s ≤150 (KV)

s ≤ 16 (ReH

)

s ≤ 670

s ≤ 16

s ≤ 16

s ≤ 16

s ≤ 16

s ≤ 16

s ≤ 16

s ≤ 16

s ≤ 16

PLEASE NOTE

8) Value ak

in J/cm2

9) A50 for thickness ≤ 5 mm

10) Measured length (Lo) = 25 mm

STEEL

STEEL

TE CHNI CA L S U P P ORT S E CTI ON [R pt ]](https://image.slidesharecdn.com/belman-expansionjointcatalogueukreducedsize-160623085016/85/Expansion-Joint-Catalogue-243-320.jpg)