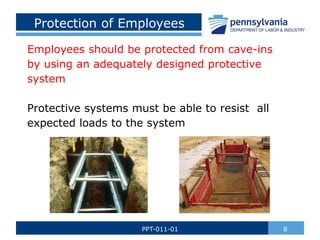

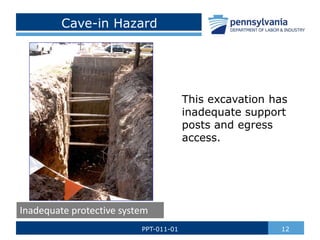

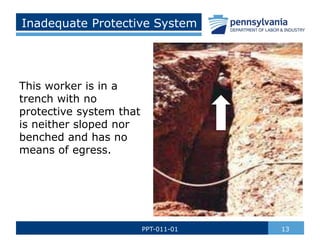

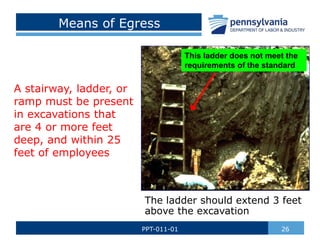

The document discusses excavation and trenching hazards. The greatest risk is cave-ins, which can be prevented by sloping, shielding, or shoring the sides of the excavation. A competent person must inspect excavation sites daily for hazards like cave-ins, hazardous atmospheres, or equipment issues. Other excavation dangers include water accumulation, toxic gas exposure, falls, and mobile equipment strikes. Proper protective systems, training, and planning are needed to safely perform excavation and trenching work.