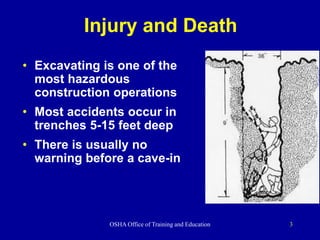

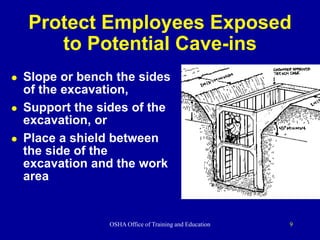

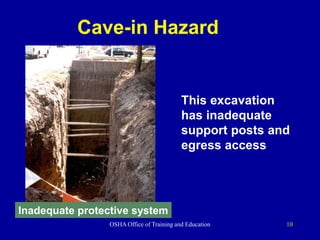

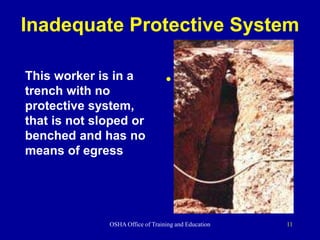

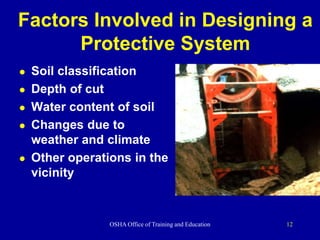

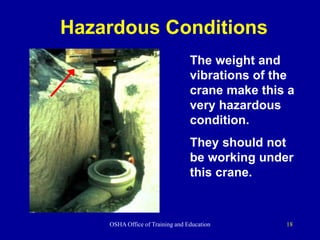

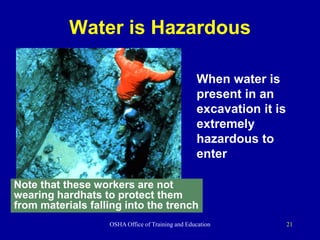

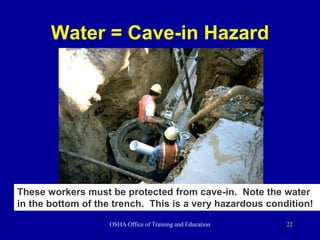

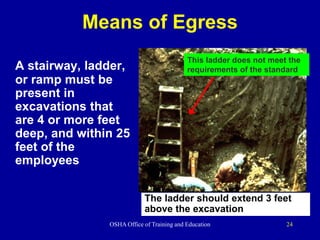

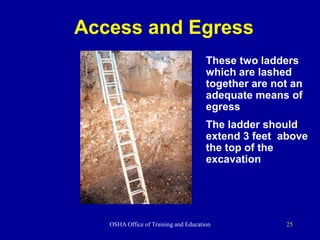

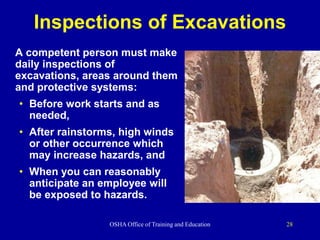

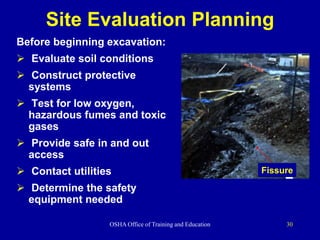

Cave-ins pose the greatest risk in excavations. Other hazards include asphyxiation, toxic fumes, fire, and mobile equipment. Most excavation accidents occur in trenches between 5-15 feet deep, where there is often no warning before a cave-in. Excavations must have adequate protective systems like sloping, shielding, or shoring to prevent cave-ins, and a competent person must inspect the site daily for hazards.