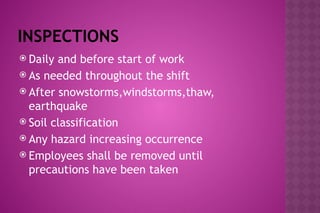

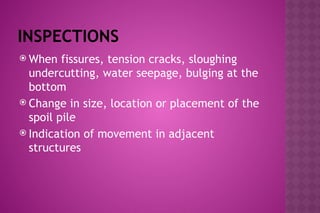

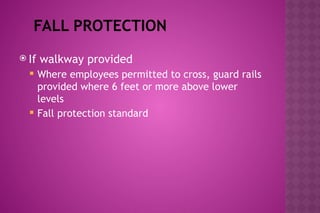

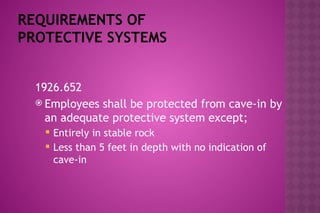

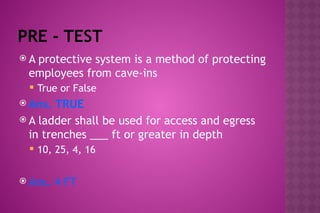

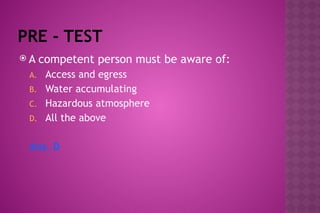

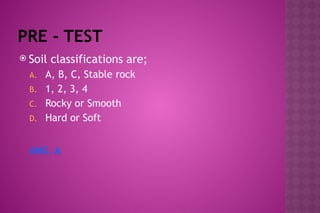

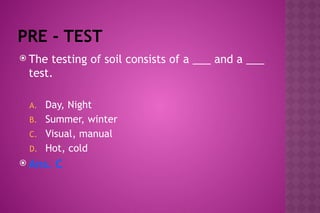

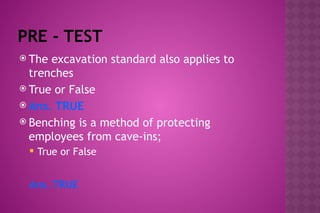

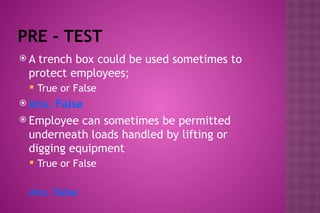

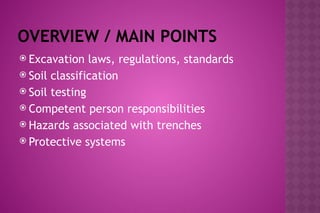

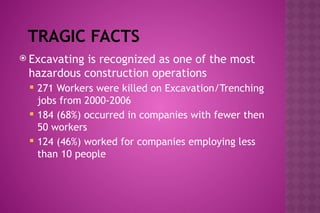

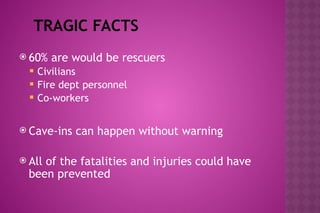

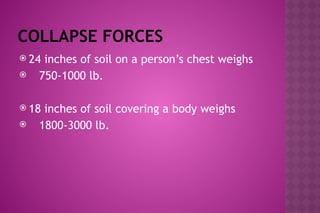

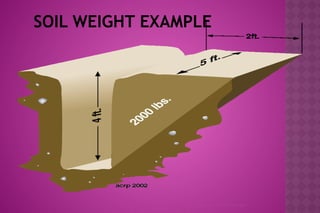

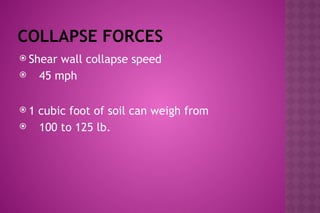

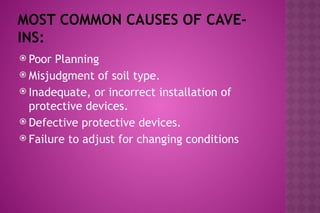

The document provides a study resource for the safety programs topic of hazard communication, hazardous energy control, and trench safety primarily for ASP examination preparation. It includes pre-test questions, outlines knowledge areas, and discusses the legal standards and best practices related to excavation and trenching safety, emphasizing the importance of proper planning and protective systems to prevent cave-ins. Tragic statistics highlight the dangers of excavation work, underscoring the need for competent individuals to oversee safe practices.

![LEGAL ASPECTS

OSHA [29 CFR 1926.650 - 652]

Excavation standard applies to all open

excavations made in the earth’s surfaces

including trenches, all surface encumbrances

that would create a hazard, and protective

systems](https://image.slidesharecdn.com/aspstudygroupsafetyprogramsparttworeviseddec132015-240903115203-0d980a01/85/ASP-Study-Group_Safety-Programs-Part-Two-Revised-dec-13-2015-pptx-28-320.jpg)