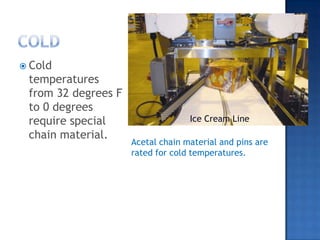

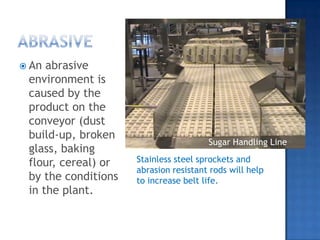

The document discusses the evaluation of chain materials for various packaging applications in environments that vary in temperature and exposure to chemicals. It highlights the properties of different chain materials, such as polypropylene, acetal, nylon, and stainless steel, and their suitability for specific conditions like cold, warm, and abrasive environments. Nercon has been a leader in manufacturing conveyor systems for the consumer goods industry for 35 years, primarily serving North American manufacturers.