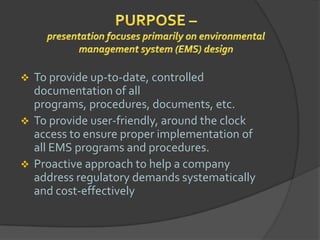

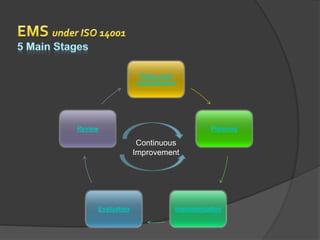

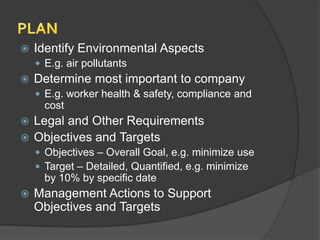

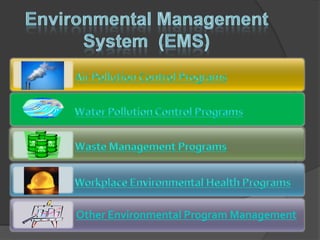

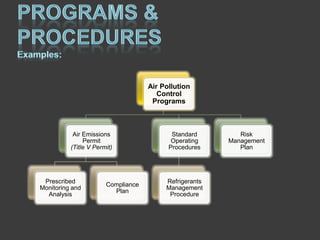

The document outlines an environmental management system (EMS) for a company. It discusses establishing an EMS policy, identifying environmental aspects and legal requirements, setting objectives and targets, implementing programs and procedures, monitoring performance, conducting management reviews, and continually improving the system. The goal is to systematically address regulatory compliance and environmental impacts in a cost-effective manner.

![WASTE MANAGEMENT

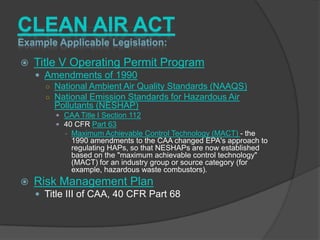

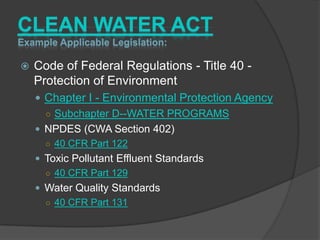

Example Applicable Legislation:

Resource Conservation and Recovery Act

(RCRA)

Non-hazardous waste/Solid waste 40 CFR Part

239-259

Hazardous waste 40 CFR Part 260 [-279]

○ Details – Part 261

Ignitable Waste (I) Corrosive Waste (C) Reactive Waste (R)

Toxicity Characteristic Waste (E) Acute Hazardous Waste (H) Toxic

Waste (T) = Characteristic waste

Specific wastes such as, slop oil emulsion solids from the

petroleum refining industry [K049] = Listed waste

Pollution Prevention Act

Toxic Substances Control Act](https://image.slidesharecdn.com/ems-13269877903421-phpapp02-120119094611-phpapp02/85/Environmental-Management-System-Development-14-320.jpg)

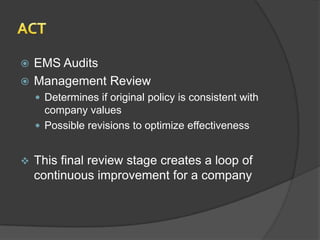

![Other Environmental

Program Management

Corporate Citizenship

EHS Management EMS Manual

Program

Tier II Reports

[Inventory of

Programs, Procedures Environmental Calendar

Substances for Compliance Reviews Policy

and work instructions and Training Schedule

Emergency

Responders]

Descriptions of Roles,

Toxic Release Inventory Responsibilities, Lists of Objectives and

Reports Authorities and Lines of Targets

Communications

Community Relations Equipment Calibration Environmental Aspects

and Communications Procedure and Impacts Inventory](https://image.slidesharecdn.com/ems-13269877903421-phpapp02-120119094611-phpapp02/85/Environmental-Management-System-Development-17-320.jpg)

![OTHER ENVIRONMENTAL

PROGRAM MANAGEMENT

Example Applicable Legislation:

Comprehensive Environmental

Response, Compensation, and Liability Act

(CERCLA) Hazardous Substances

[Superfund]

Superfund Amendments and

Reauthorization Act (SARA)

Emergency Planning and Community Right-to-

Know Act (EPCRA) [also known as SARA Title III]

○ Tier II Report [SARA 311/312] – Inventory of

Substances for Emergency Responders, 40 CFR

Part 370

○ Toxic Release Inventory Report – [SARA 313] Tier

III Report](https://image.slidesharecdn.com/ems-13269877903421-phpapp02-120119094611-phpapp02/85/Environmental-Management-System-Development-18-320.jpg)