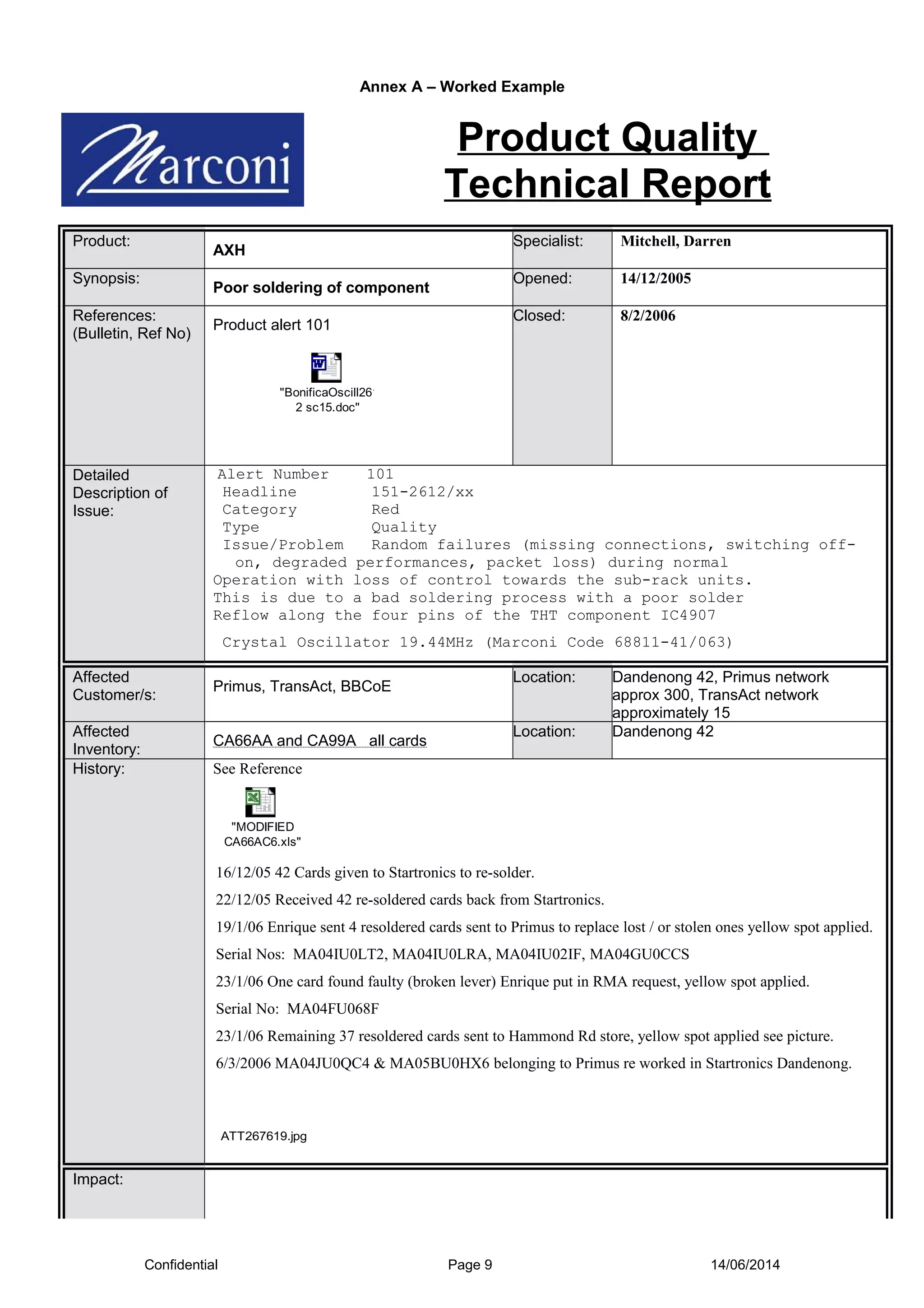

Smith, John

e:

AXH-123

Details:

During final test of AXH-123, poor soldering was noted on the following components:

- Resistors R1, R2, R3

- Capacitors C1, C2

The solder joints were dry and cracked. This is likely caused by insufficient solder being applied during wave soldering.

Corrective Action:

The wave soldering process was reviewed and the following changes implemented:

- Solder pot temperature increased by 5 degrees C to improve wetting

- Dwell time over the wave increased by 1 second to allow better filling of joints

- Solder paste application checked to