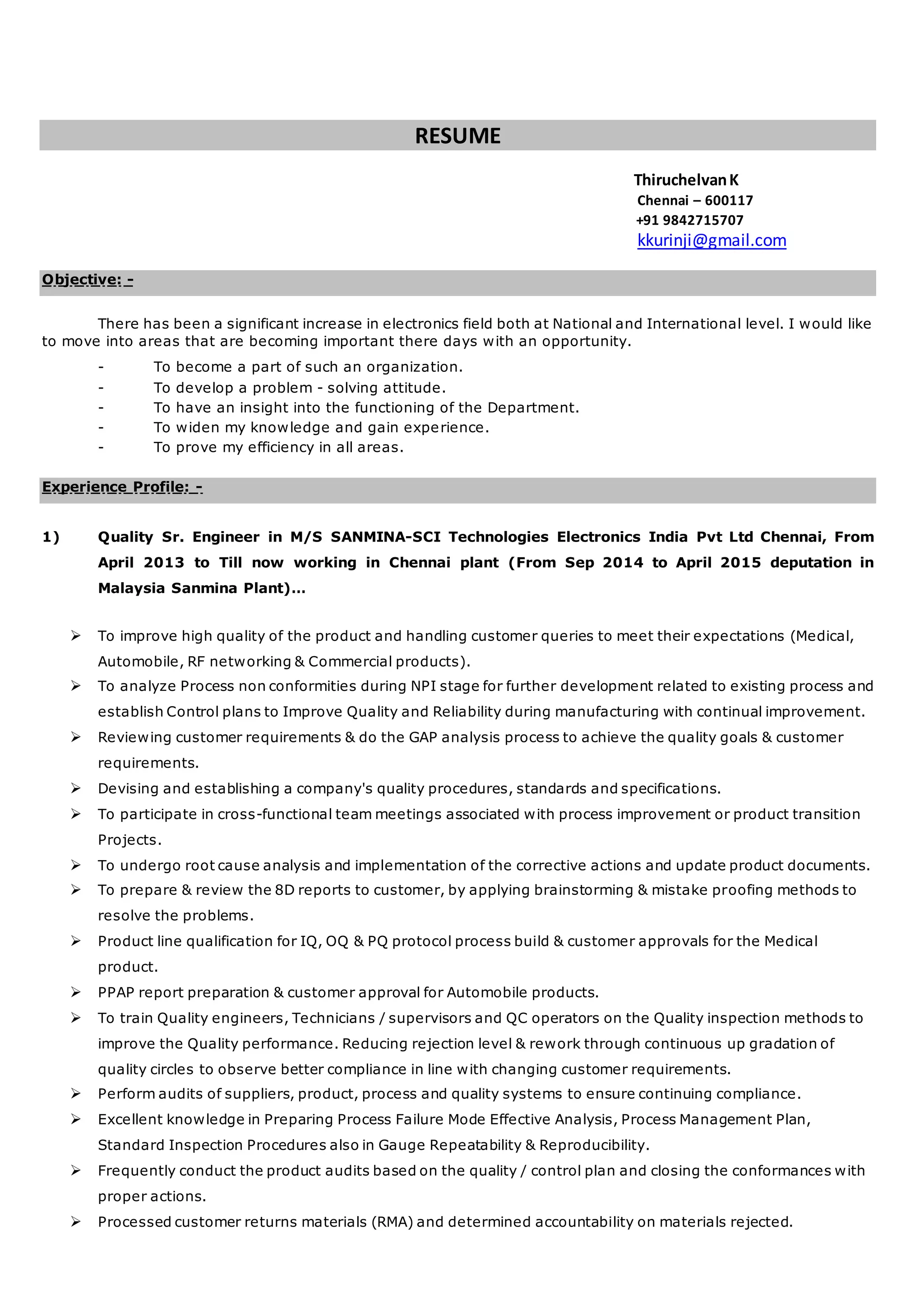

Thiruchelvan K is seeking a position that allows him to utilize his experience in quality assurance and engineering. He has over 15 years of experience in roles of increasing responsibility at electronics manufacturing companies. His experience includes quality control, process improvement, supplier management, auditing, and training. He is proficient in quality methodologies like ISO, APQP, FMEA, SPC, and has certifications in Six Sigma and VDA auditing.