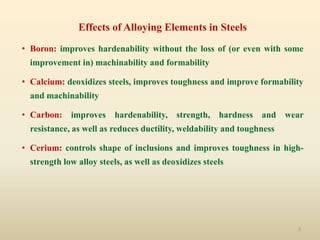

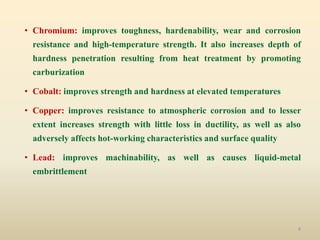

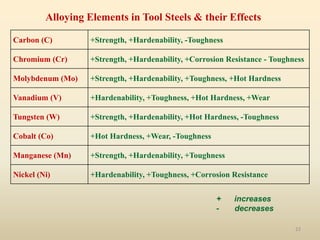

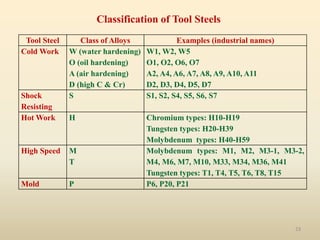

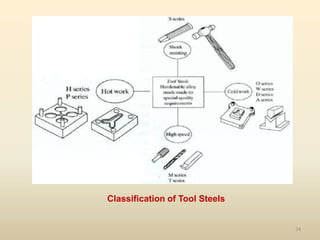

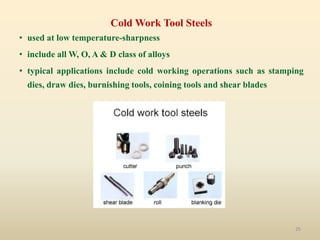

This document discusses different types of alloy and special steels. It begins by outlining general categories including carbon and alloy steels, stainless steels, tool and die steels, and cast steels. It then describes the effects of various alloying elements on steel properties. The remainder of the document provides more detailed information about specific steel types, including their compositions, properties, and applications.