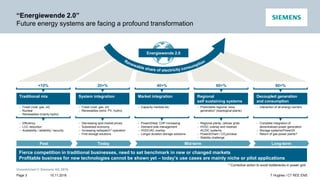

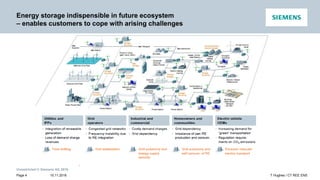

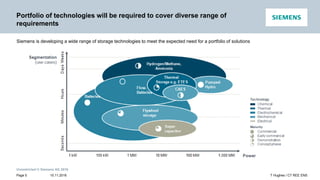

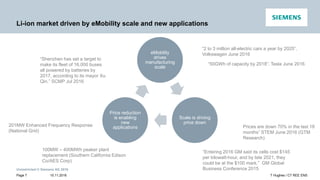

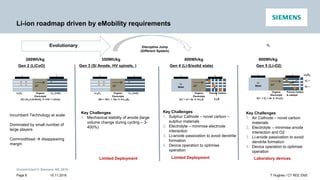

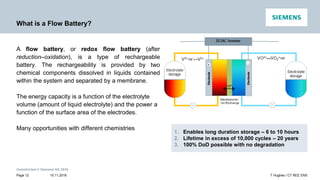

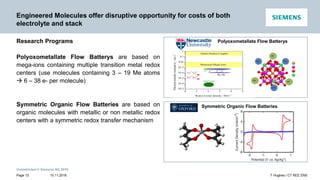

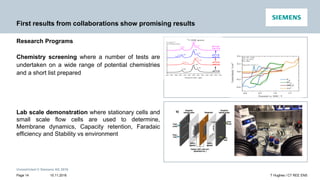

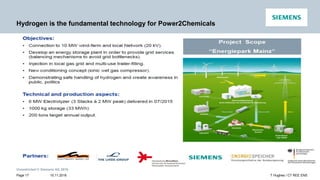

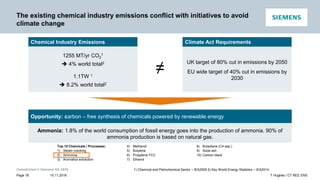

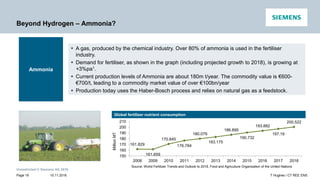

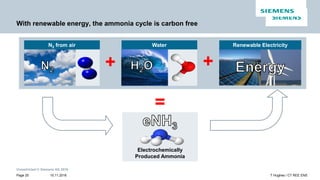

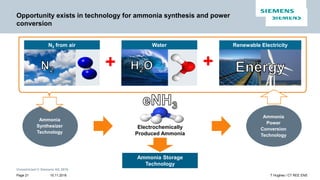

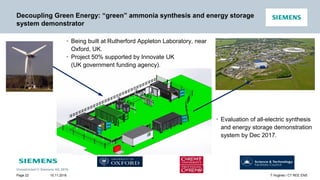

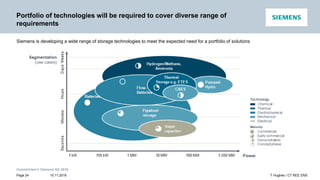

The document discusses the transformation of energy systems and the critical role of energy storage technologies beyond lithium-ion batteries. It highlights advancements in various areas, including flow batteries and the electrification of the chemical industry, particularly focusing on ammonia production as a carbon-free method. Siemens is developing a comprehensive portfolio of storage technologies to meet future energy needs.