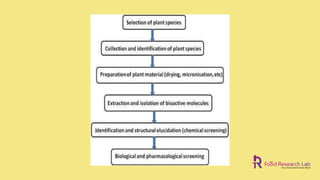

This document summarizes different techniques for extracting bioactive components from plants, including conventional methods like Soxhlet extraction and maceration as well as modern green techniques. Some key modern techniques discussed are microwave assisted extraction, ultrasound assisted extraction, supercritical fluid extraction using carbon dioxide, and deep eutectic solvent extraction. These green techniques have advantages over conventional methods like faster extraction rates, more effective energy use, reduced equipment needs, and preservation of bioactive compounds. The document provides details on how each technique works and its advantages.