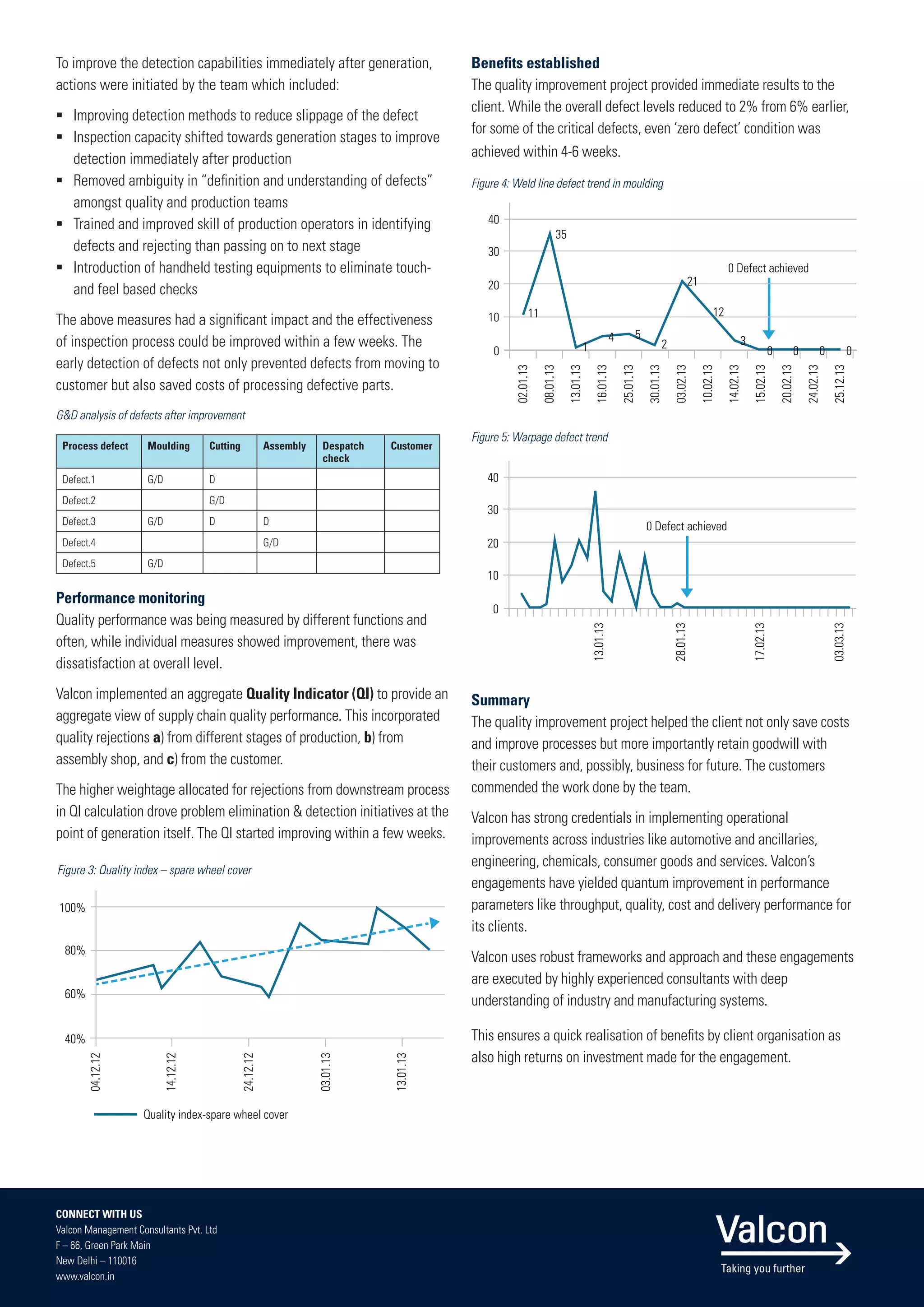

Valcon helped a plastic component manufacturer address quality defects that were impacting profitability and customer satisfaction. Valcon conducted a study of the manufacturing processes and quality systems, identifying issues with defect generation, inspection, and performance monitoring. They implemented process validation trials to optimize parameters, improved inspection methods, and created a quality index to track aggregate performance. These changes helped reduce defects from 6% to 2% within weeks, achieving zero defects for some critical issues, and improved relationships with customers.