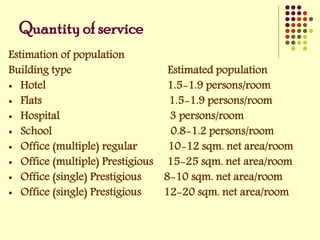

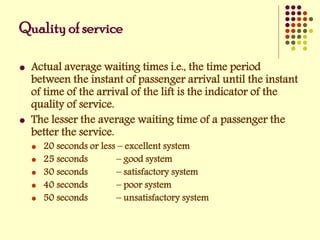

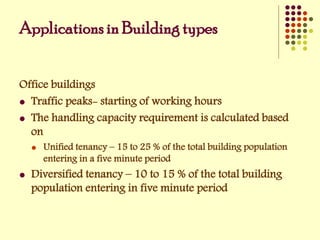

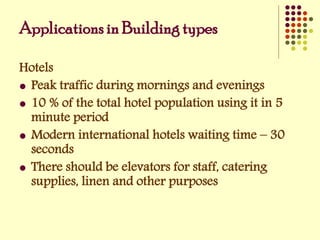

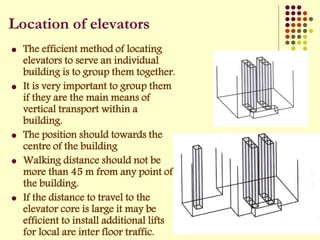

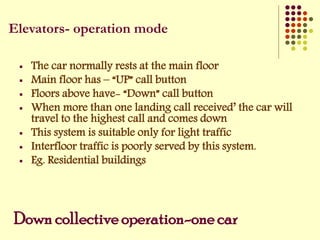

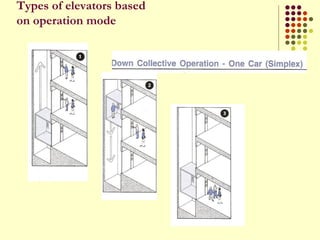

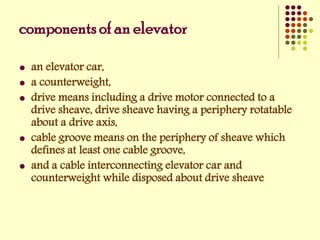

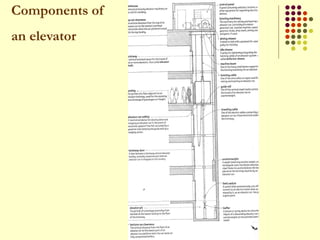

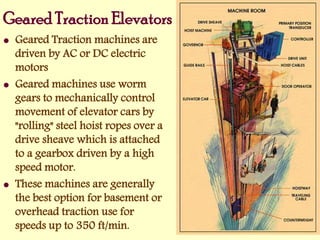

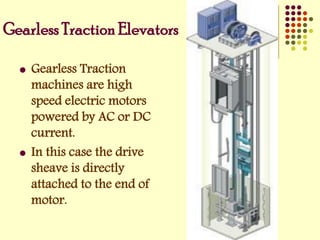

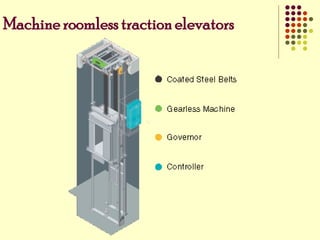

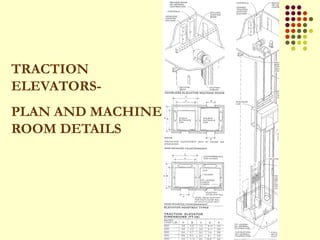

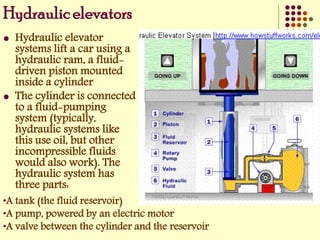

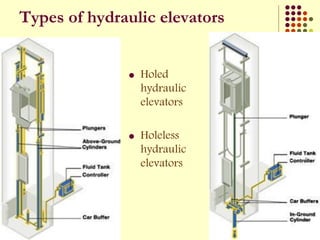

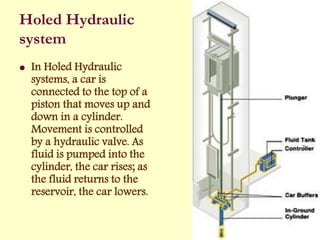

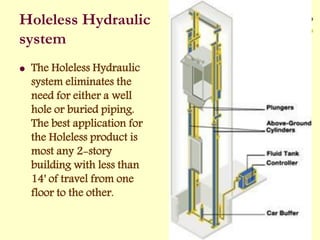

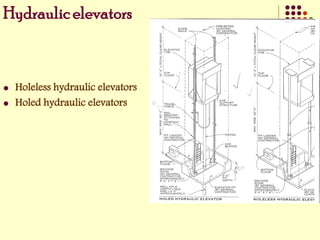

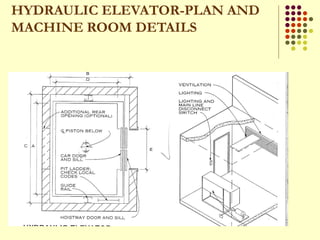

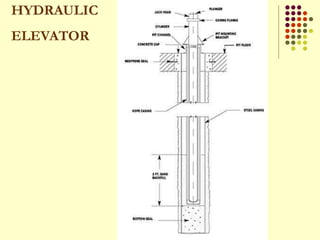

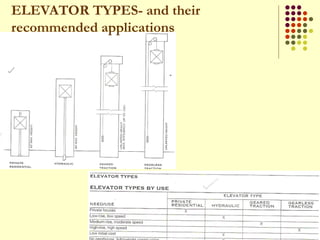

This document discusses different types of elevators, including traction and hydraulic elevators. It covers the history of lifts and how modern lift components remain largely the same. Traction elevators can be geared or gearless, while hydraulic elevators are either holed or holeless. The document examines lift applications for different building types like offices, hotels, hospitals and residential buildings. It also discusses lift operation modes, comfort factors, and components of elevator systems.