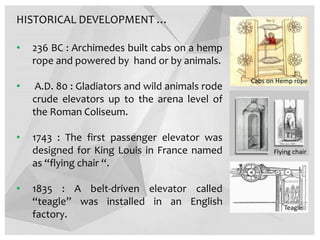

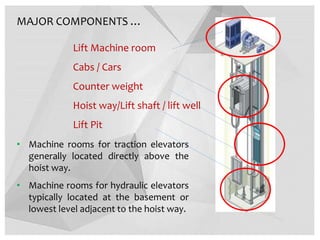

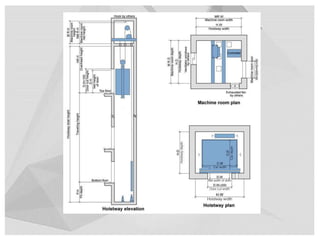

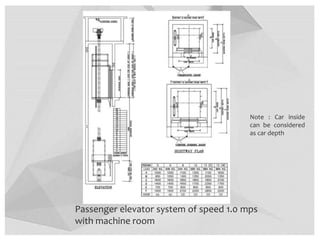

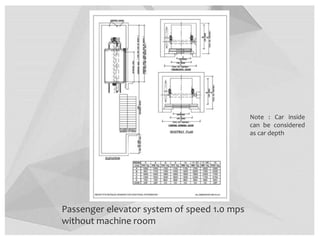

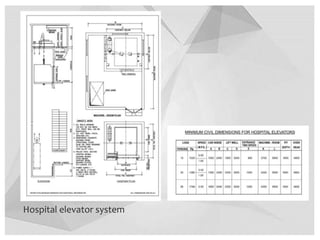

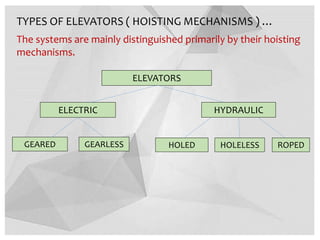

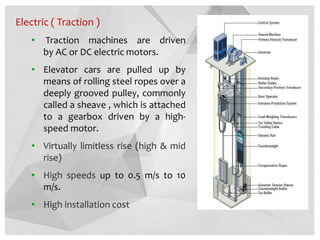

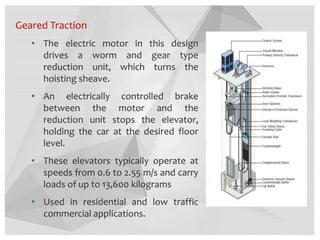

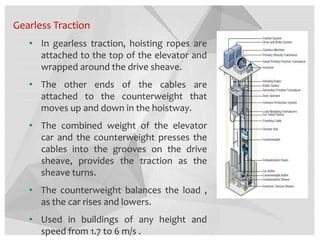

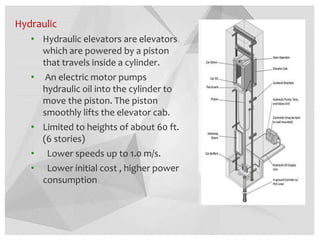

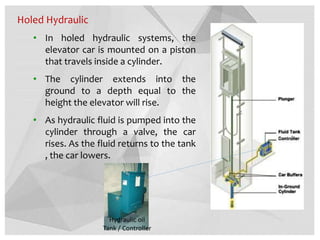

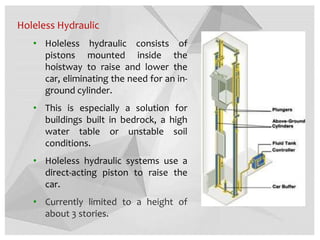

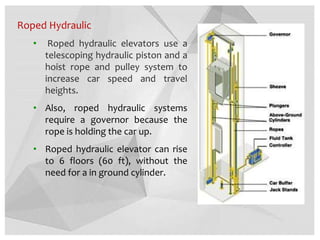

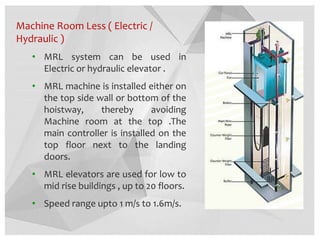

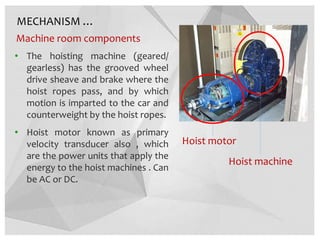

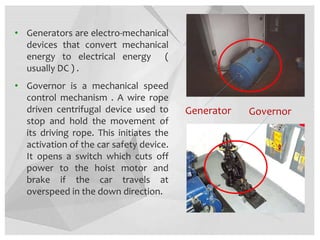

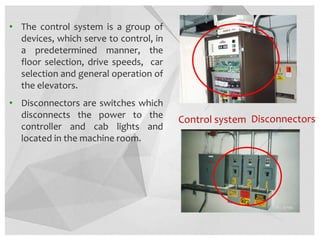

This document provides information about elevators, including their need, historical development, major components, types, mechanisms, controls, and details for accessibility. It discusses how elevators allow for tall buildings and transport goods and people between floors. Key developments include ancient lifting devices, early safety brakes, electric and hydraulic systems, and standards for speed and capacity. Elevator types include passenger, hospital, freight, automobile and more. Components, mechanisms for traction, hydraulic and roped systems, and safety controls are outlined. Accessibility requirements for physically challenged individuals are also reviewed.