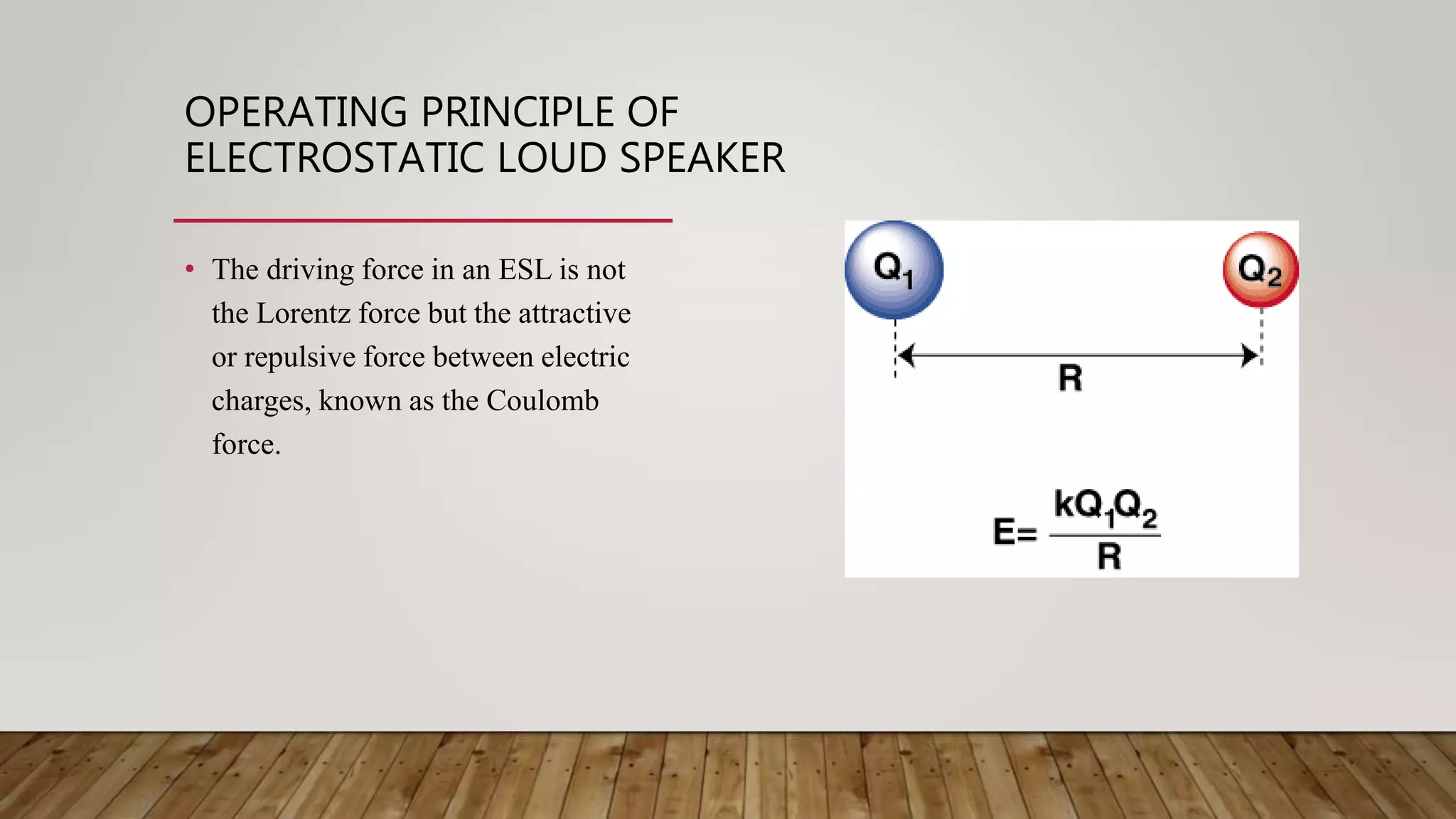

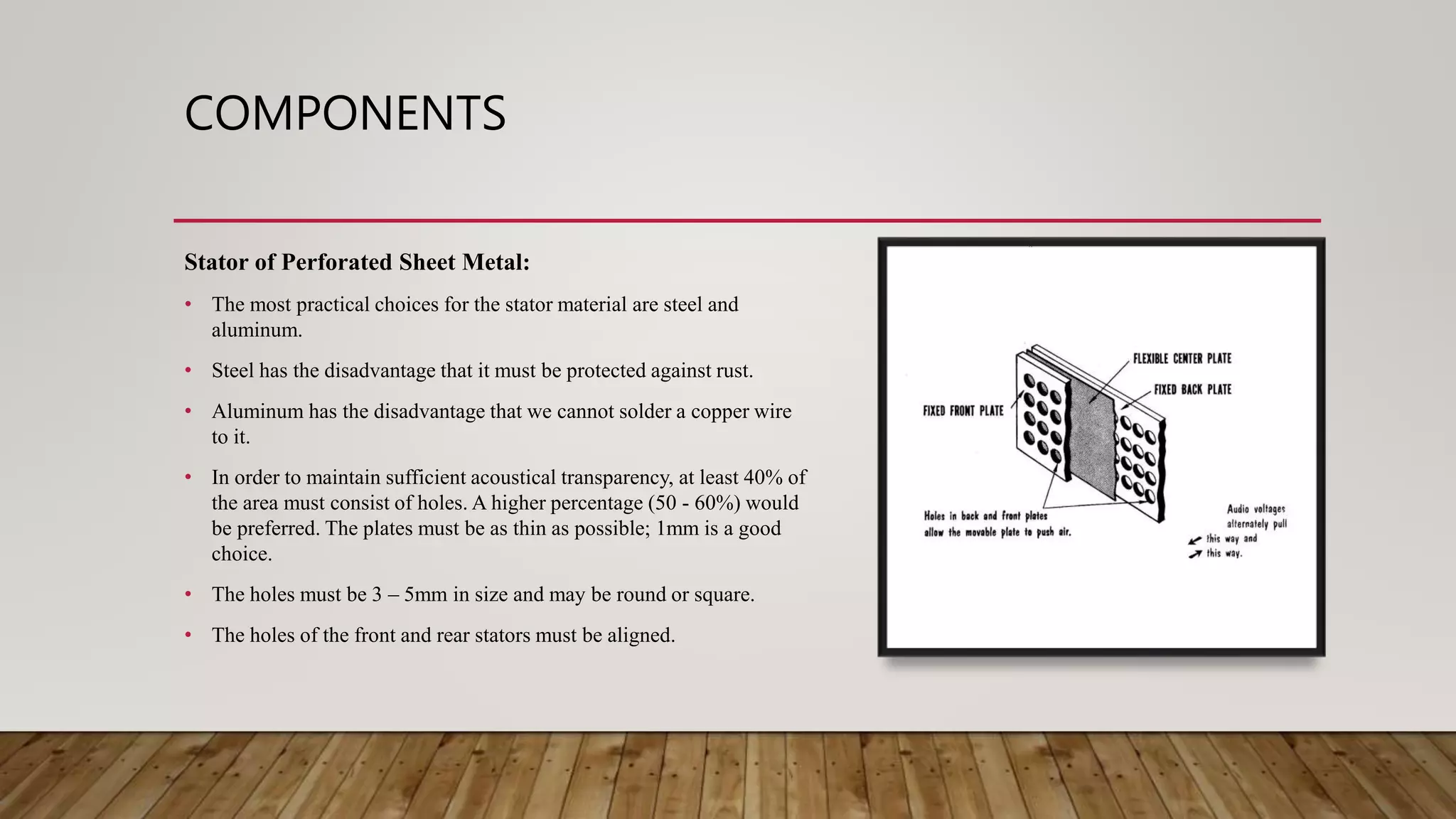

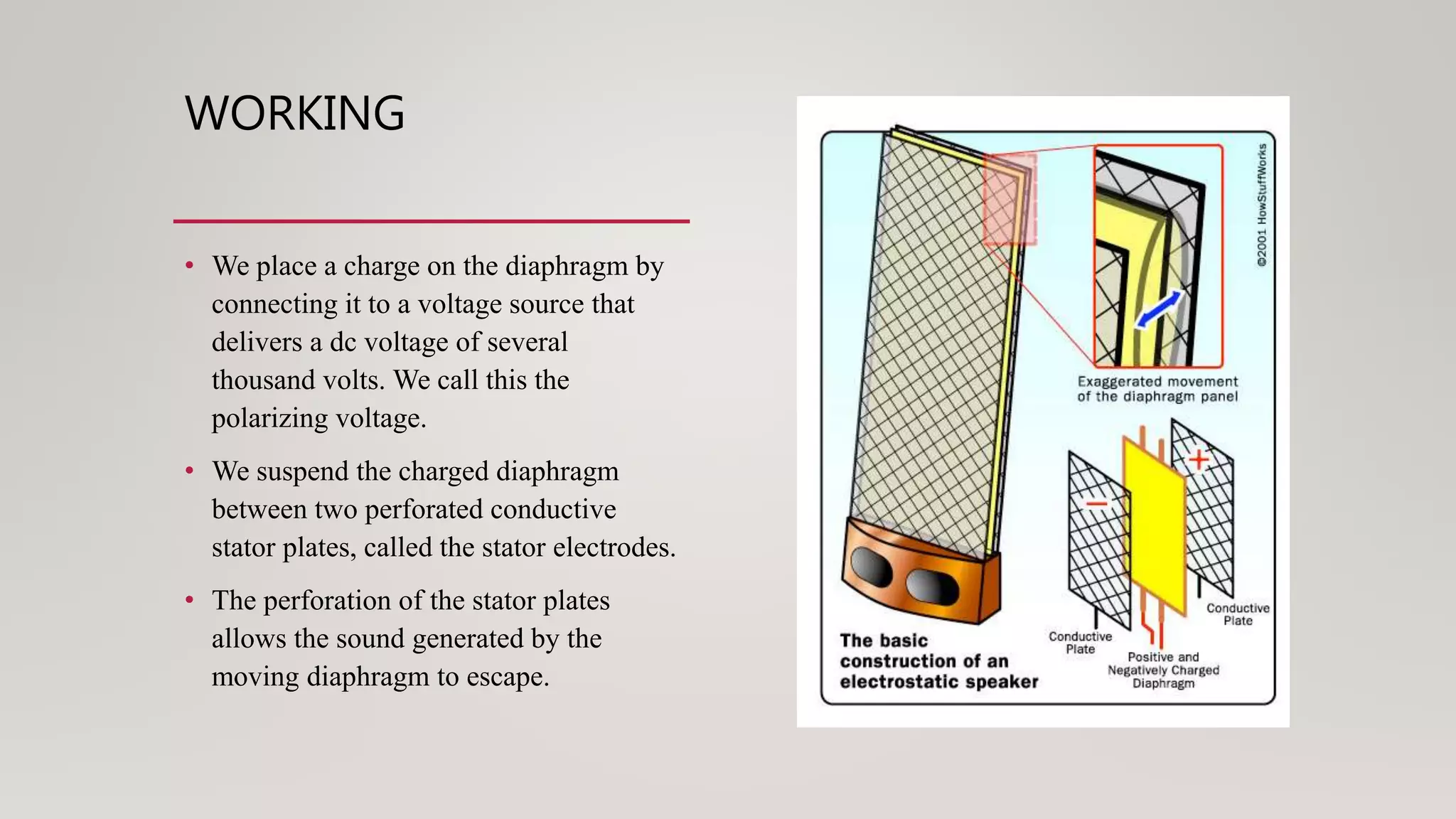

The document provides an overview of electrostatic loud speakers, detailing their construction, operation, and components such as the diaphragm, stator plates, and audio transformer. The operation relies on electrostatic forces rather than the Lorentz force, utilizing a charged diaphragm and perforated conductive stator plates to generate sound. It highlights the advantages, such as superior sound quality and low distortion, alongside drawbacks like high cost and sensitivity to humidity.