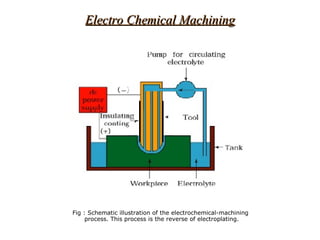

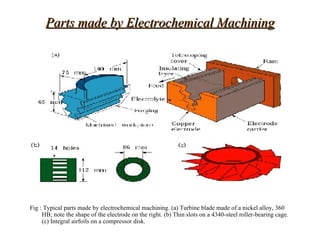

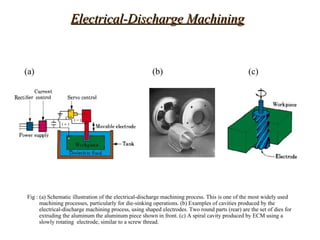

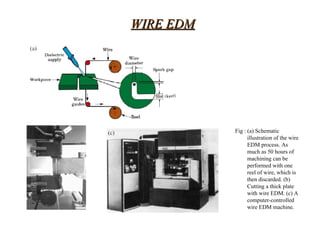

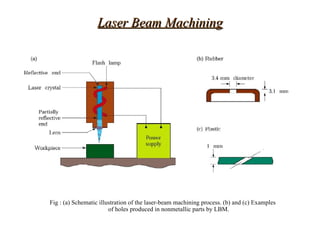

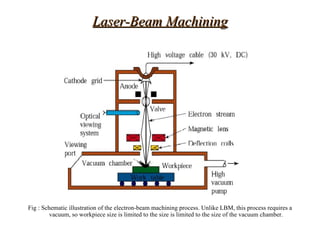

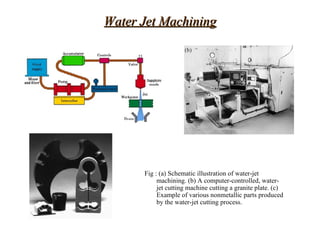

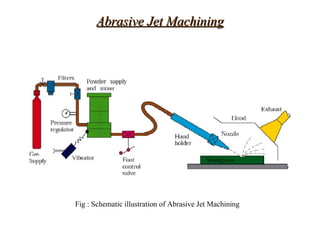

This document provides an overview of advanced machining processes including chemical machining, electrochemical machining, electrical discharge machining, laser beam machining, water jet machining, and abrasive jet machining. It describes the basic mechanisms and capabilities of each process. Examples are given of complex parts that can be manufactured using these processes like biomedical implants, turbine blades, and microscopic gears. Nanofabrication techniques are also discussed for producing extremely small features at the micro and nanoscale.