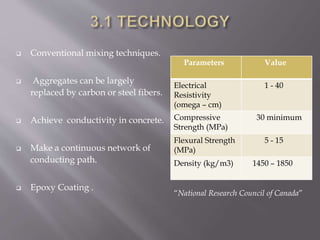

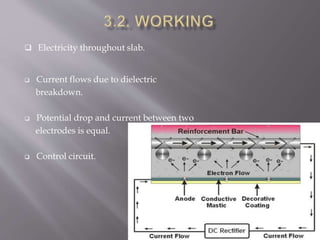

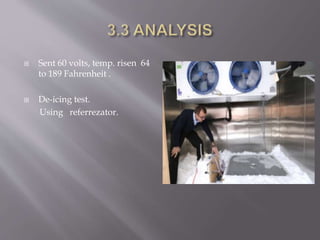

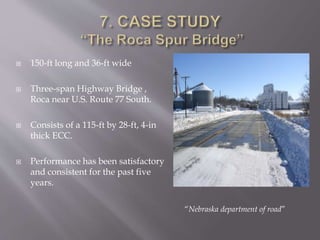

This document discusses electrically conductive concrete. It provides an introduction and literature review on the technology. Electrically conductive concrete is produced by adding conductive components like carbon or steel fibers to create a continuous conducting path. This gives the concrete both electrical conductivity and mechanical strength properties. The document analyzes the characteristics of electrically conductive concrete such as resistivity and compressive strength. It explores applications for de-icing of structures, electrical grounding, and preventing corrosion. A case study is presented on a bridge in Nebraska that has used electrically conductive concrete successfully for five years. The conclusion is that this concrete has benefits like reducing environmental pollution and preventing electric shock hazards while remaining economical.