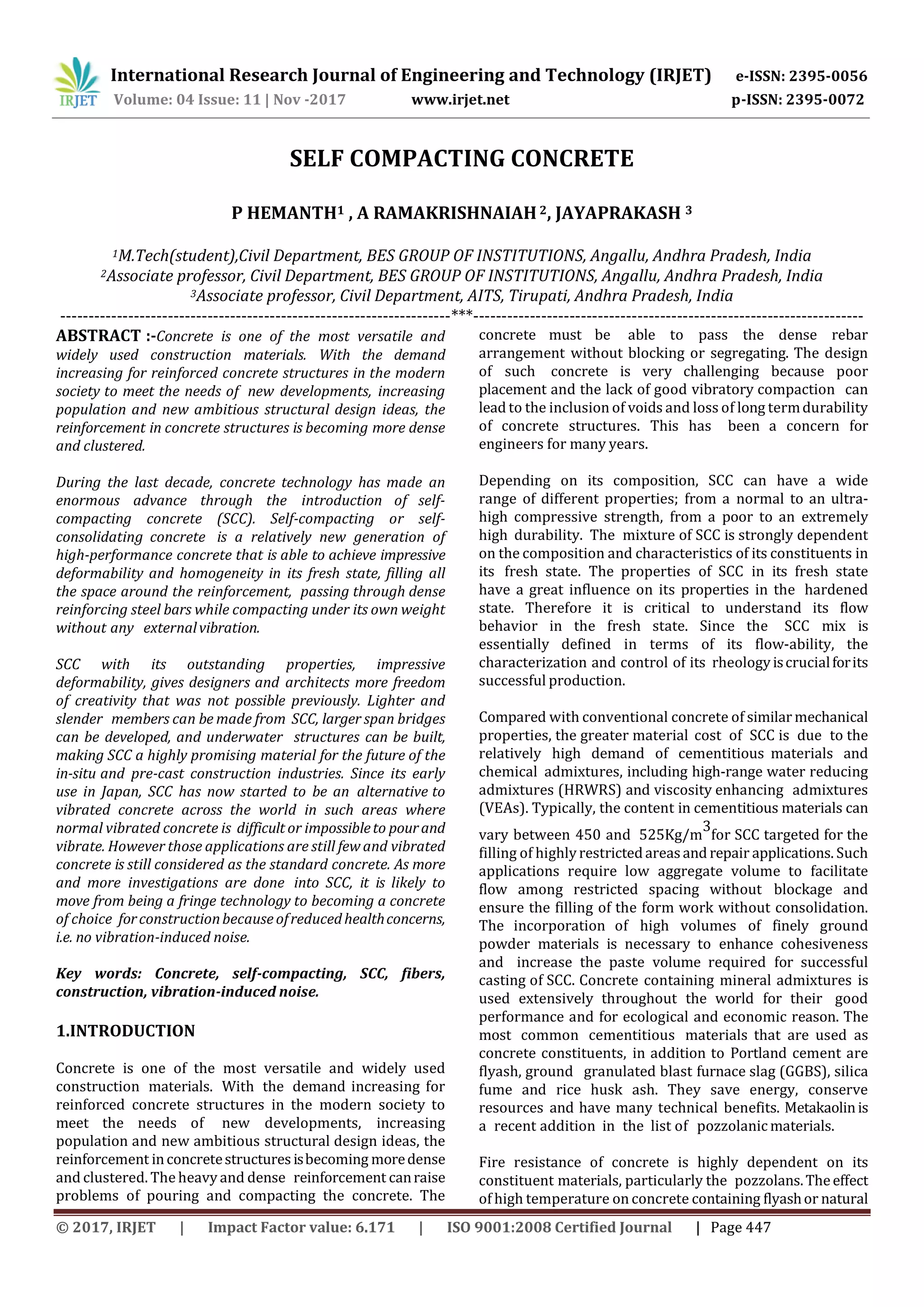

This document discusses self-compacting concrete (SCC), which is a type of concrete that can flow and consolidate under its own weight without any external vibration. SCC has advantages over traditional vibrated concrete such as easier placement in complex forms, reduced noise pollution, and improved surface finish. The key properties of SCC include high flowability, passing ability, and segregation resistance. These properties are achieved through optimizing the mix design, including using a high range of superplasticizer, limiting coarse aggregate content, increasing fine particles and viscosity modifying agents. SCC has applications in structures with dense reinforcement like the Burj Khalifa where it simplified construction. The document also discusses experimental investigations into the compressive strength of SCC exposed to

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 04 Issue: 11 | Nov -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 6.171 | ISO 9001:2008 Certified Journal | Page 453

Scope for further work

Based on the present study, the following aspects

have been suggested for further study.

The present study was conducted by using Fly ash

and Micro silica as mineral admixtures. Further

study can be extended for HSSCC with, Rice husk

ash, Metakolin and Micro silica as mineral

admixtures.

Further the study can be extended by designing the

concrete with different types of aggregates as the

retention in mass of concrete at elevated

temperatures is highly influenced by the type of

aggregate.

Further the studycan beextended onstudyofmicro

structure by using SEM and X-ray analysis.

REFERENCES

1. Okamura, H. and Ouchi, M. [1]“Self-compacting concrete”.

Journal of advanced concrete technology, 2003, Vol.1, No.1,

pp 5-15.

2. Nan Su, Kung –Chung Hsub and His-Wen Chai.[2] “A

simple mix design method for self-compacting concrete”.

Cement and Concrete Research, 2001,Vol.31,pp1799-1807.

3. Subramanian, S. and Chattopadhyay D .[5] “Experiments

for mix proportioning of Self – compacting concrete”, The

Indian Concrete Journal, 2002, pp.13-20

4. V. Mallikarjuna Reddy, Dr. M.V Seshagiri Rao, [10]

“Performance of High Strength Self Compacted Concrete

Exposed to elevated temperatures”.

BIOGRAPHY:

PALLI HEMANTH

CIVIL ENGINEERING

GVIC,BES INSTITUTIONS

ANGALLU,MADANAPALLI,

CHITTOOR DIST,

ANDHRA PRADESH-517325](https://image.slidesharecdn.com/irjet-v4i1175-171208091726/75/Self-Compacting-Concrete-7-2048.jpg)