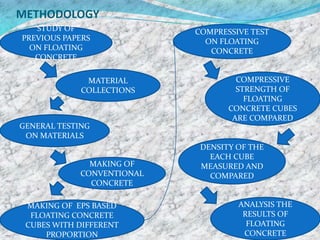

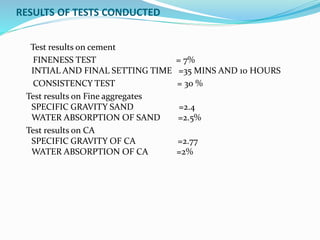

This document describes an experimental study on floating concrete conducted by a group of students. Floating concrete is a type of lightweight concrete with a density lower than 1000 kg/m3 that floats on water. The study aims to identify lightweight materials that can be used to make concrete float while maintaining strength. Extended polystyrene (EPS) beads are used to replace conventional aggregates and reduce the density. The methodology involves preparing EPS-based floating concrete cubes with different proportions and testing their compressive strength and density. Test results of the raw materials are also presented.

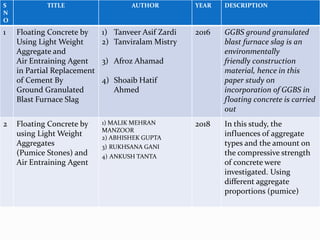

![The utilization of extended polystyrene in development has

parcel of preferences contrast and the utilization of traditional

materials which brings about practical future. The utilization of

EPS Beads likewise decreases the ecological dangers that causes

during its removal. The majority of this sort of waste is late

unnoticed and they will prompt an Earth-wide temperature

boost[2]. The utilization of Lightweight concrete (LWC) has been

a component in the development business for a considerable

length of time, yet like other material the desires for the

exhibition have raised and now we are expecting a steady, solid

material and unsurprising attributes. Lightweight concretes can

either be light weight aggregate concrete, frothed concrete or

autoclaved circulated air through. The development business

wherever faces the issues and difficulties; two-third of the world

surface is secured with water. It is in this manner not amazing

that there has been a lot of action with concrete in the ocean in

late decades](https://image.slidesharecdn.com/floatingconcrete-220802023218-4260f9fa/85/FLOATING-CONCRETE-pptx-4-320.jpg)