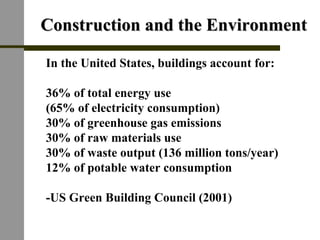

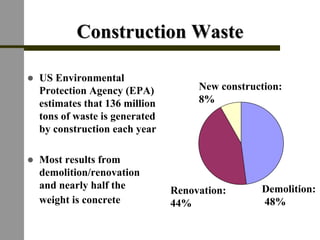

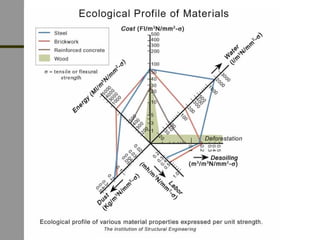

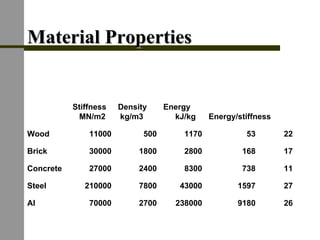

This document provides an overview of concrete structures and design methods for reinforced concrete. It discusses sustainable construction topics like whether concrete is a green material. The key points are:

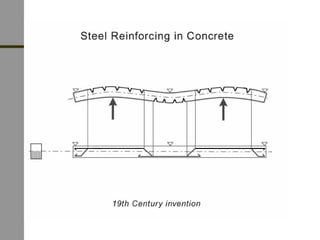

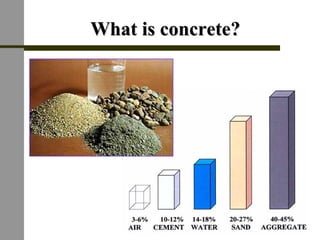

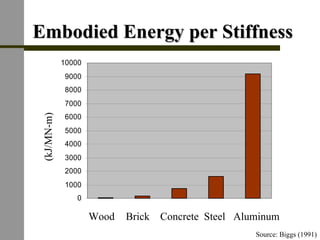

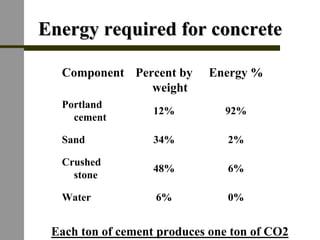

1) Concrete is made from abundant local resources like water, aggregate and cement and can incorporate waste materials, making it environmentally friendly.

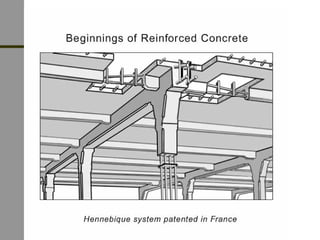

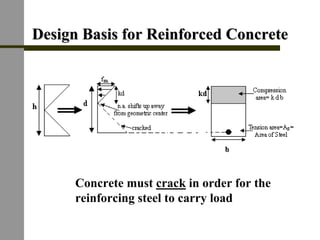

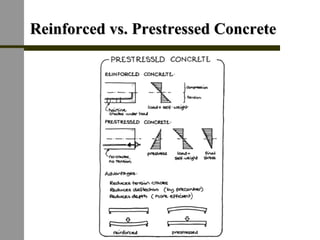

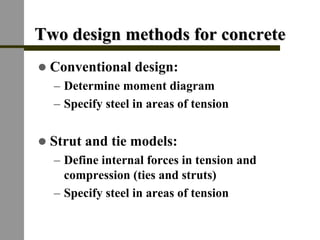

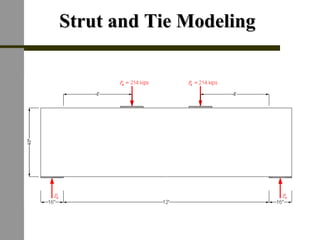

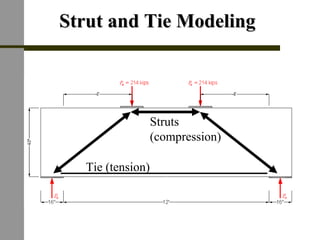

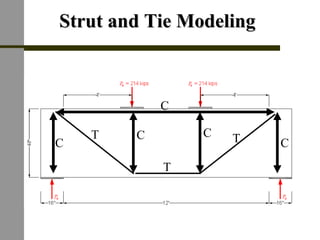

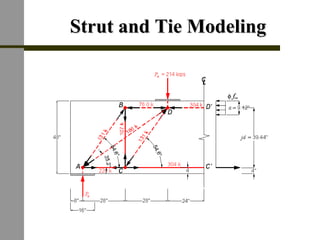

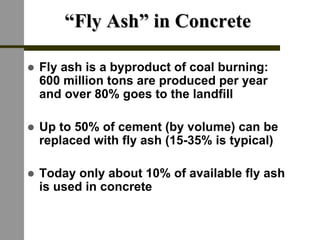

2) There are two main design methods - using moment diagrams or strut and tie models - and incorporating fly ash and minimizing corrosion can improve sustainability.

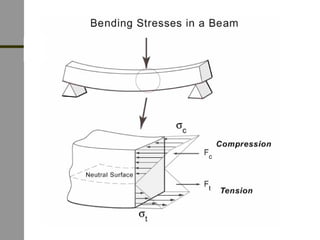

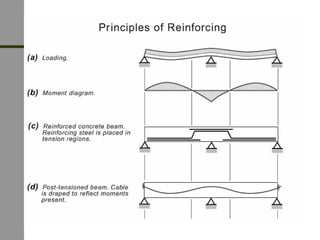

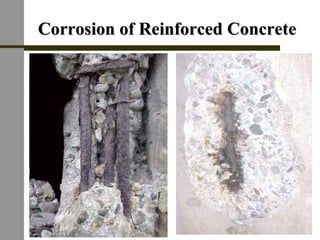

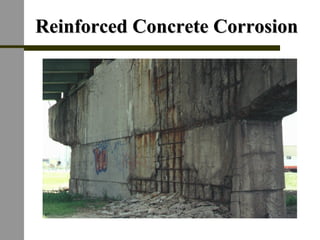

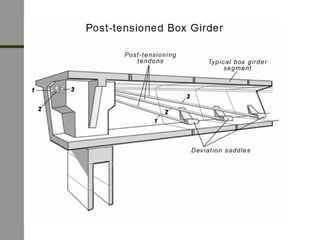

3) While concrete has benefits, reinforced concrete must crack to work and rebar corrosion is a durability issue, whereas prestressed concrete prevents cracking.