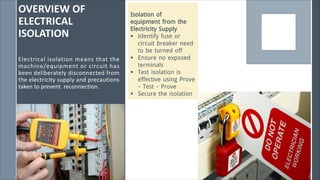

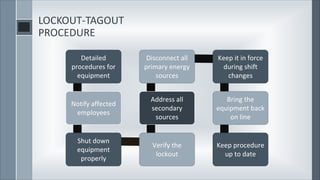

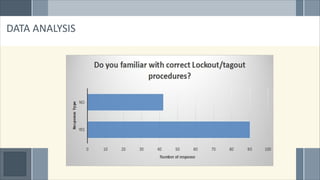

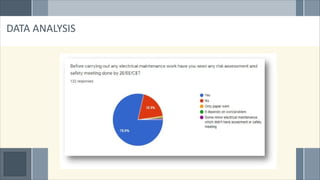

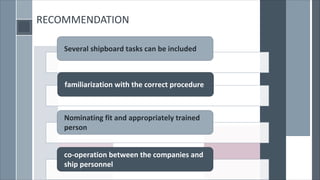

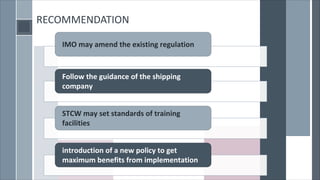

The document discusses the implementation of safe electrical isolation procedures on ships to minimize electrical accidents and enhance the safety of the working environment. It identifies the main causes of incidents, emphasizes the importance of proper training, and provides recommendations for improving compliance with safety regulations. The findings highlight the need for support and awareness among crew members to prevent accidents related to electrical systems onboard.