1) The document discusses the basics of electrical drives and control, including the history of drives from the first DC motor in 1838 to widespread use of AC motors in industries in the 1890s.

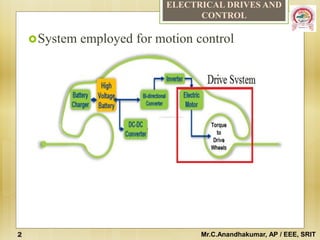

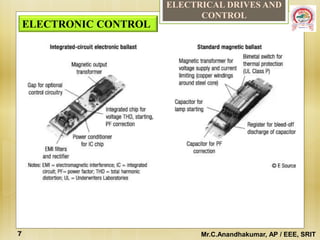

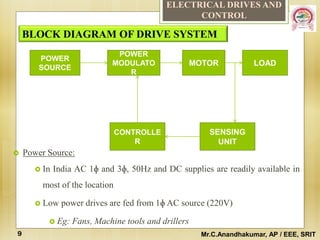

2) It describes the components of a typical drive system including the power source, power modulator, controller, and motor load. Power modulators convert and modulate power using devices like rectifiers, inverters, and choppers.

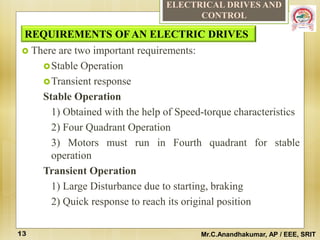

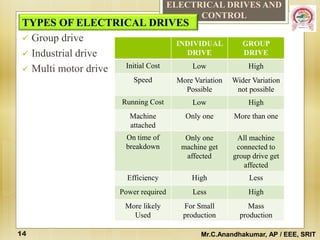

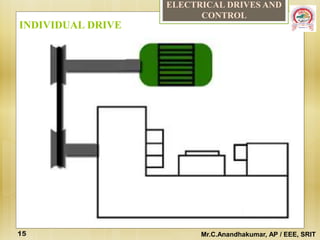

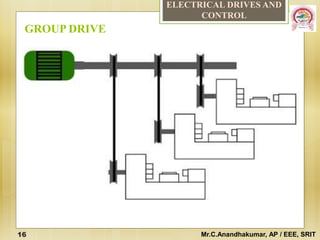

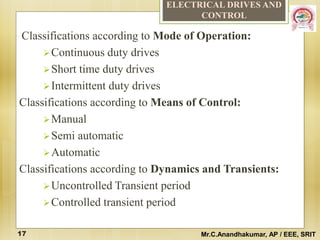

3) Electrical drives are classified based on their mode of operation, means of control, and dynamics. Individual drives power a single machine while group drives power multiple machines from a common source.