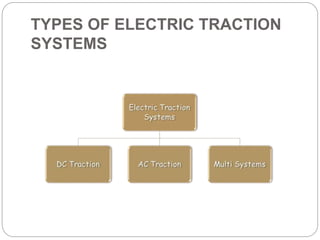

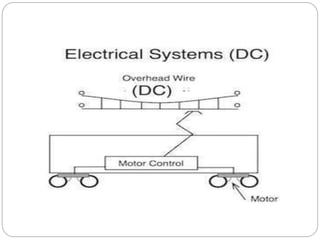

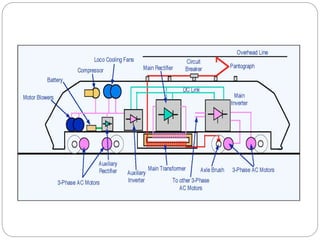

This document provides an overview of electric traction systems used in railways. It discusses the main types including DC traction which uses direct current from overhead lines or third rails, and AC traction which uses alternating current from overhead lines. The major components of electric traction systems are also outlined, such as traction substations, overhead lines, current collectors, traction transformers, power electronics, traction motors, and tracks. Multi-system trains that can operate under different voltages are also described.