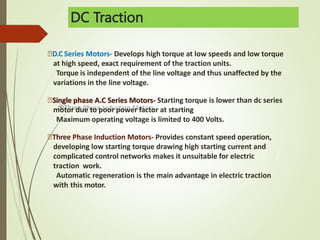

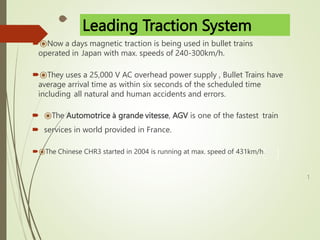

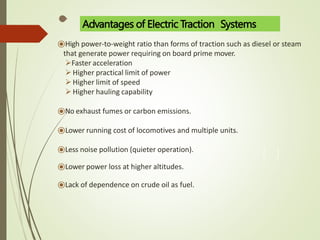

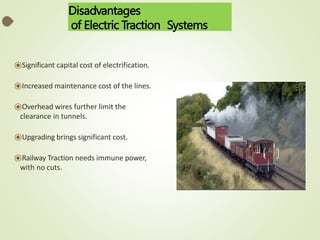

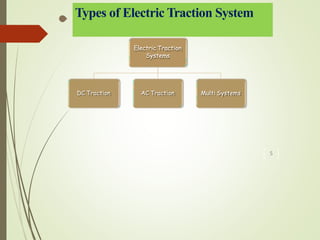

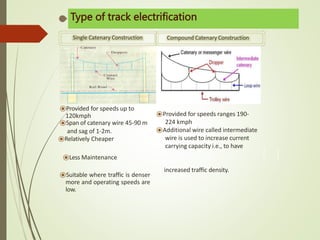

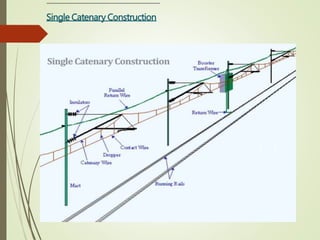

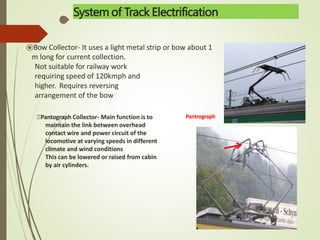

This document summarizes a seminar presentation on electric traction. It defines electric traction as using electric motors powered by electric power for traction systems like railways and trams. It then provides a brief history of electric traction, including its introduction in India in 1925 using 1.5kV DC power. The document discusses the typical voltages used for electric traction in India and the different types of traction systems, including DC, AC, and multi-systems. It also covers topics like types of track electrification, pantograph collectors, traction motors, leading high-speed traction systems, and the advantages and disadvantages of electric traction systems.

![1. [1]Traction transformer

2. [2]Traction converter [3]Traction

control

3. Train Control and Monitoring System

4. Traction motor

5. [6]Diesel engine generator

[7]Auxiliary converter

[8]Battery charger

[9]Energy storage

Overview of Traction Engine](https://image.slidesharecdn.com/electricaltractionsystemsw-230501062953-7ee57c3a/85/ELECTRICAL-TRACTION-SYSTEM-SW-1-pptx-12-320.jpg)