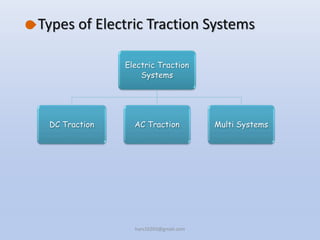

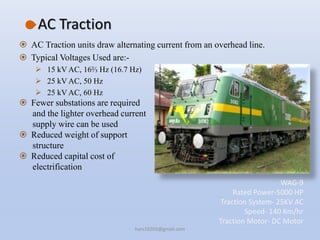

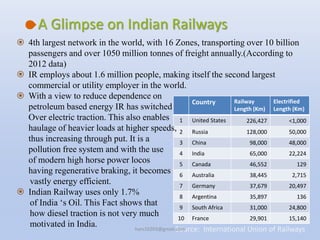

Siddiqui Arshad hussain presented on electric traction. Electric traction involves using electric motors and power for traction systems like railways and trams. Early electric traction systems used direct current from overhead wires or rails, while most modern systems use alternating current. India's rail network uses both 1.5kV DC and 25kV AC systems. Electric traction provides advantages over steam and diesel systems like higher acceleration, power, and speeds as well as lower emissions and maintenance costs.