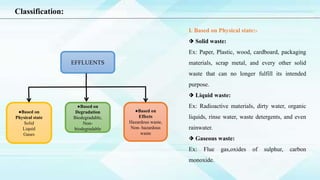

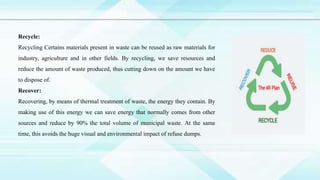

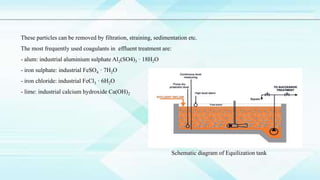

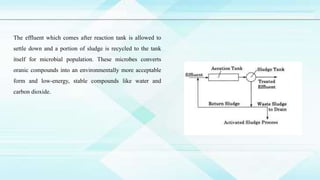

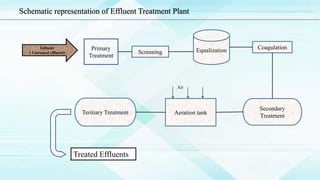

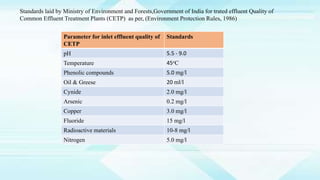

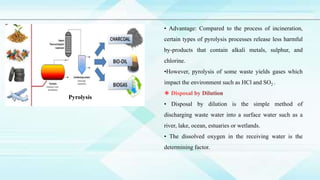

This document discusses effluents, which are materials discarded from industrial processes into the environment. It classifies effluents based on physical state (solid, liquid, gas) and degradability (biodegradable, non-biodegradable). Sources of effluents include various industries. Effluents can have harmful effects and require management systems. Effluent treatment plants use various physical, chemical, and biological processes to treat effluents before disposal or reuse. Laws exist in different countries to regulate effluent management.