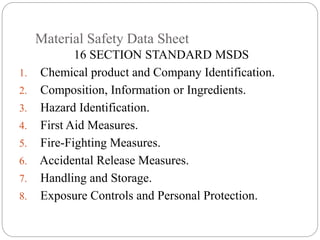

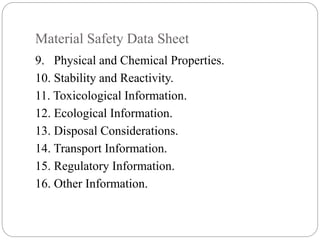

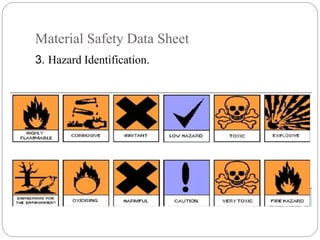

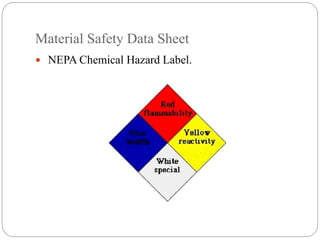

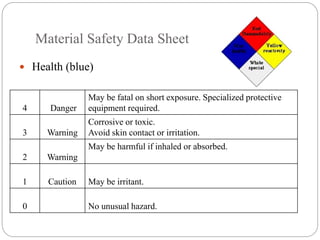

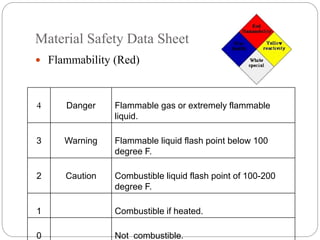

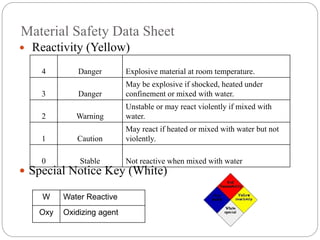

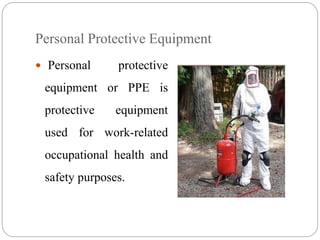

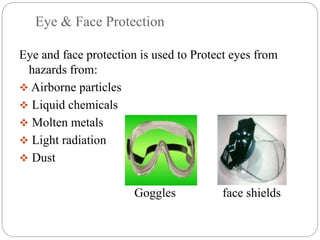

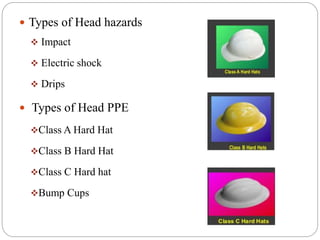

This document discusses industrial safety and personal protective equipment (PPE). It defines industrial safety as activities to reduce, control, and eliminate hazards from industries. The objectives are to prevent accidents, eliminate work stoppages, and promote employee morale. Material safety data sheets (MSDS) provide chemical identification and hazard information. PPE like eye protection, head protection, hand protection, foot protection, and respiratory protection are important to protect workers from hazards and injuries on the job.