This document summarizes research on using model predictive control (MPC) for optimizing the operation of large-scale drinking water networks. Key points:

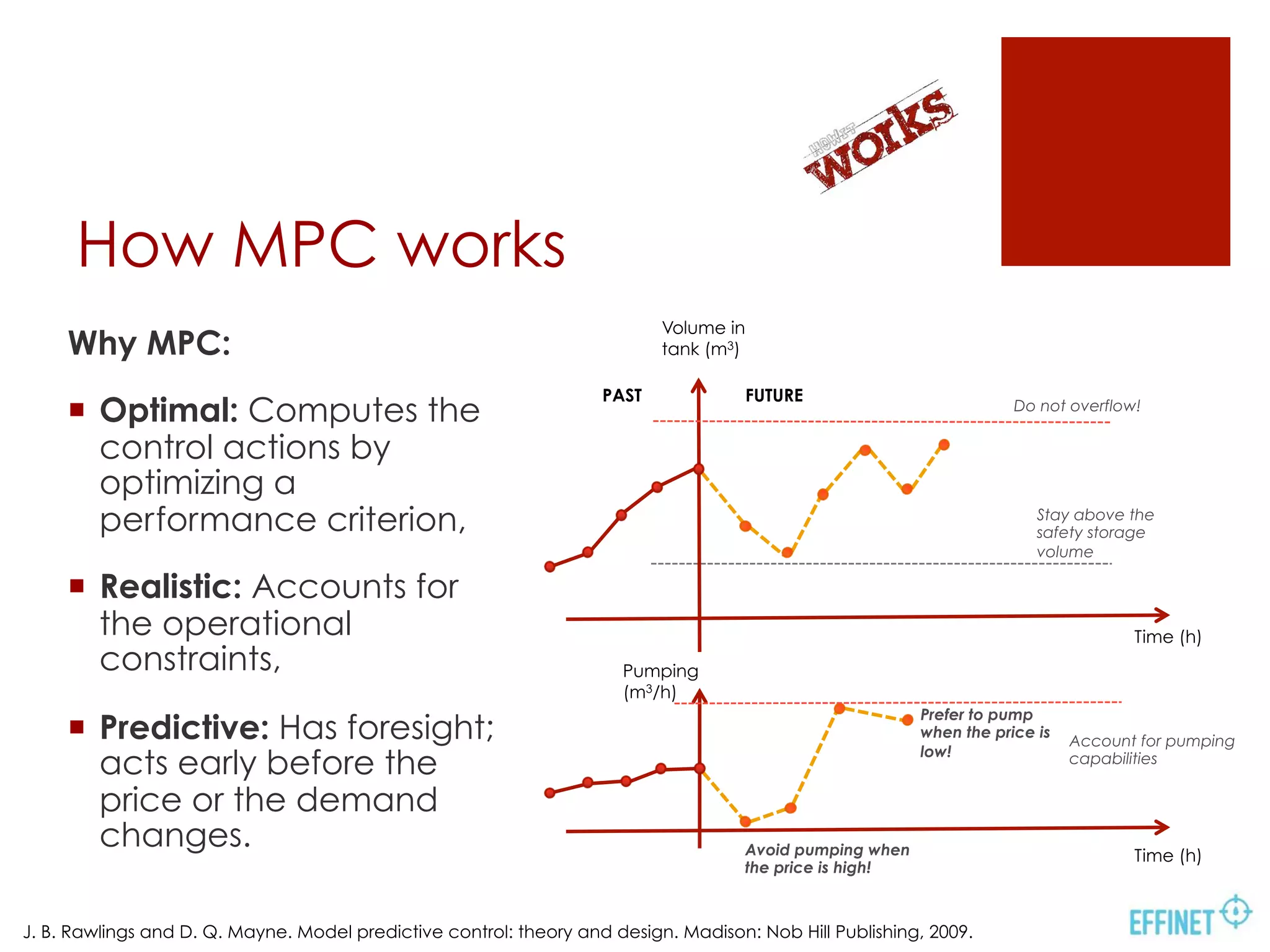

- MPC aims to reduce energy costs while meeting demand and respecting constraints, using forecasts of water demand and energy prices.

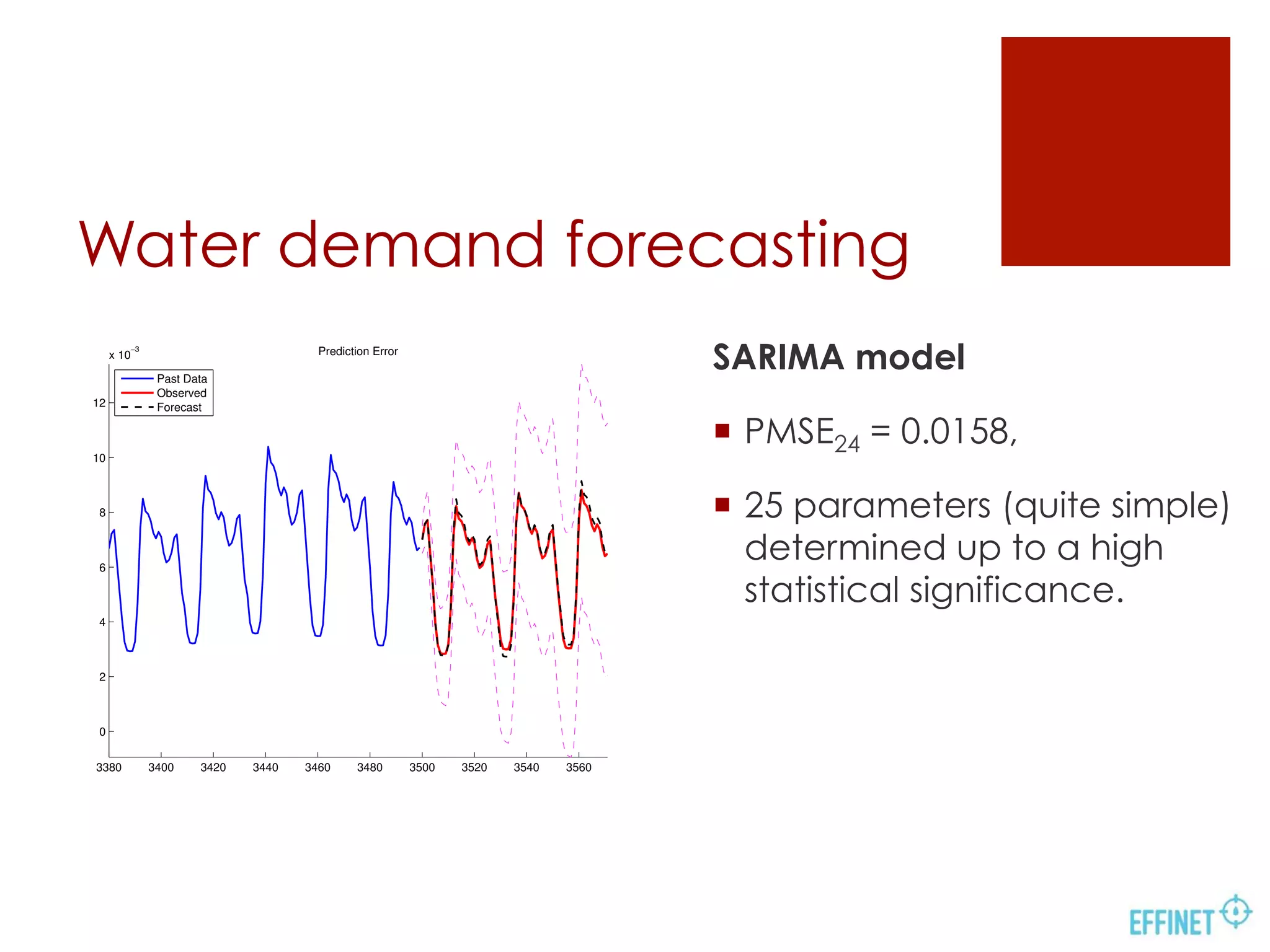

- Demand is forecasted using SARIMA, BATS and RBF-SVM models, with RBF-SVM achieving the best accuracy.

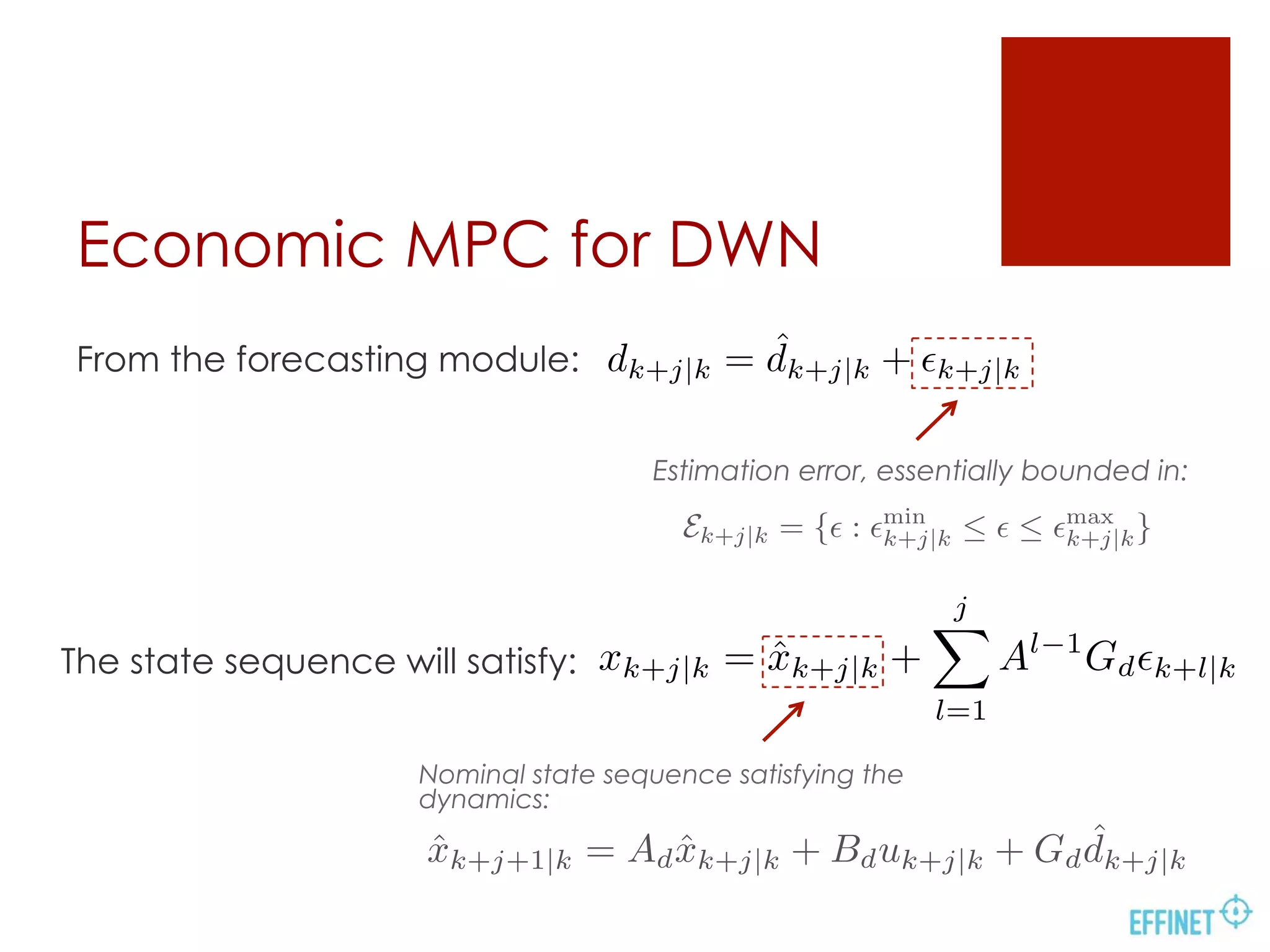

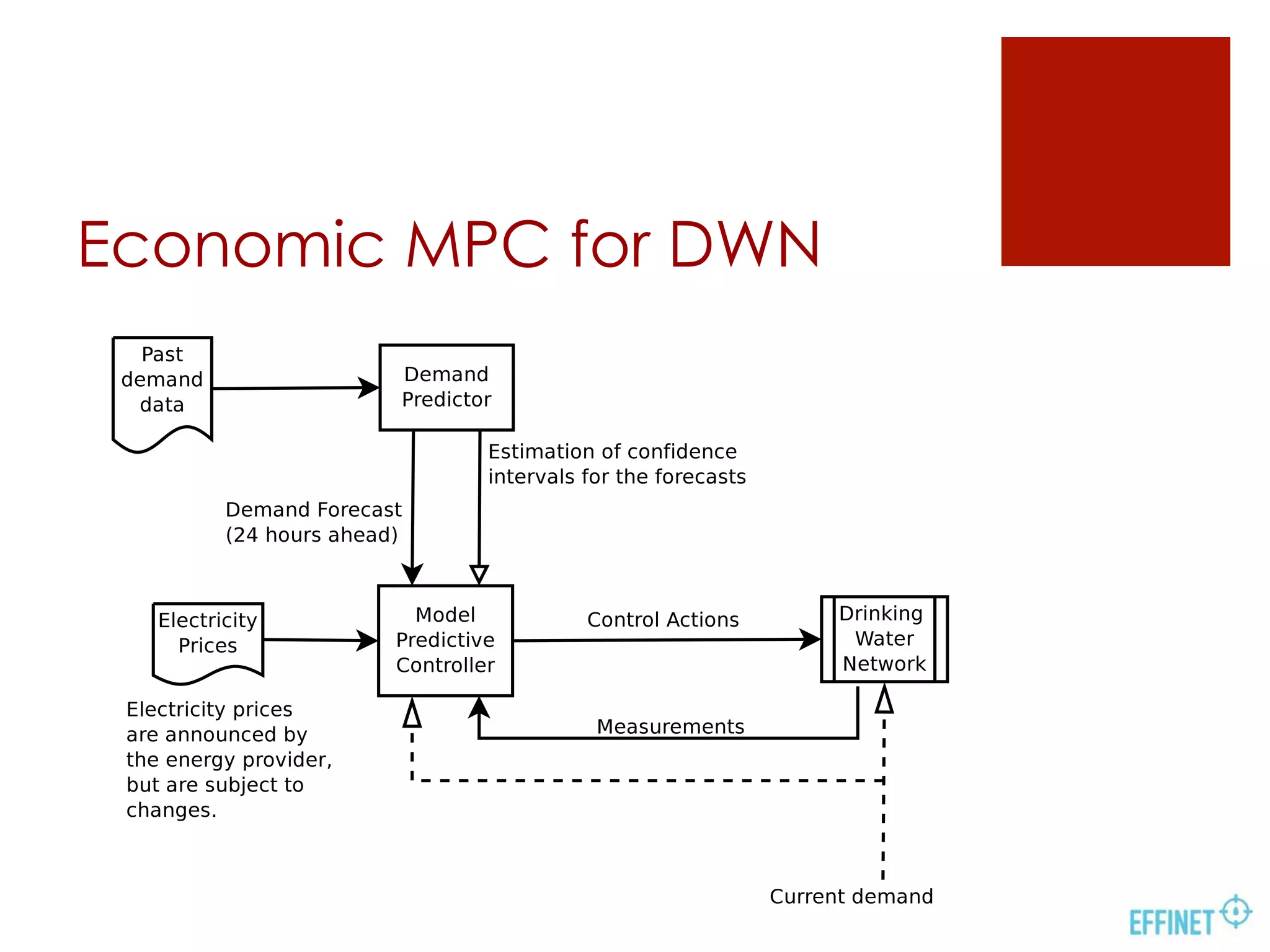

- A hydraulic model is developed to predict network state based on inputs, disturbances, and constraints.

- MPC optimizes pumping over a horizon while respecting constraints, using demand forecasts to anticipate future needs.

- Simulation results on a real network show MPC achieving low costs while

![Water demand forecasting

RBF-SVM model

¡ PMSE24 = 0.0065,

¡ 229 parameters (complex),

¡ 10-fold cross-validation

gave q2 = 0.9952,

¡ Explanatory variables:

200 past demands plus a

set of binary calendar

variables,

¡ Stringent confidence

intervals.

3250 3260 3270 3280 3290 3300 3310 3320

3

4

5

6

7

8

9

10

x 10

−3

Time [hr]

Demand[m

3

hr

−1

]

RBF−SVM Prediction](https://image.slidesharecdn.com/effinetifacpresentation-140819051639-phpapp01/75/Water-demand-forecasting-for-the-optimal-operation-of-large-scale-water-networks-8-2048.jpg)

![0 20 40 60 80 100 120 140 160 180 200

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

Time [h]

WaterDemandFlow[m3

/h]

Forecasting of Water Demand

FuturePast

Water demand forecasting

BATS model

¡ Box-Cox transformation,

ARMA errors, Trends and

Seasonality,

¡ PMSE24 = 0.0043,

¡ with just 26 parameters,

¡ Very stringent confidence

intervals.](https://image.slidesharecdn.com/effinetifacpresentation-140819051639-phpapp01/75/Water-demand-forecasting-for-the-optimal-operation-of-large-scale-water-networks-9-2048.jpg)

![Economic MPC for DWN

4500 4505 4510 4515 4520 4525 4530 4535 4540 4545

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

x 10

4

Time [hr]

Volume[m3

]

Safety Volume

Minimum Volume

Maximum Volume

MPC Upper Bound

MPC Lower Bound

Predicted Trajectory

Closed−loop trajectory

ˆxk+j|k 2 X

iM

j=1

Aj 1

GdEk+j|k

Bounds on the predicted state

sequence calculated by:

The sparsity of Gd enables this

computation!](https://image.slidesharecdn.com/effinetifacpresentation-140819051639-phpapp01/75/Water-demand-forecasting-for-the-optimal-operation-of-large-scale-water-networks-13-2048.jpg)

![Economic MPC for DWN

4500 4505 4510 4515 4520 4525 4530 4535 4540 4545

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

x 10

4

Time [hr]

Volume[m3

]

Safety Volume

Minimum Volume

Maximum Volume

MPC Upper Bound

MPC Lower Bound

Predicted Trajectory

Closed−loop trajectory

ˆxk+j+1|k = Ad ˆxk+j|k + Bduk+j|k+

+ Gd

ˆdk+j|k

Predicted state sequence

according to:](https://image.slidesharecdn.com/effinetifacpresentation-140819051639-phpapp01/75/Water-demand-forecasting-for-the-optimal-operation-of-large-scale-water-networks-14-2048.jpg)

![MPC: Performance

10 20 30 40 50 60 70 80 90

0.2

0.4

0.6

0.8

MPC Control Action (1~20)

ControlAction

10 20 30 40 50 60 70 80 90

0.2

0.4

0.6

0.8

MPC Control Action (21~46)

ControlAction

10 20 30 40 50 60 70 80 90

0

0.1

0.2

Time [hr]

WaterCost[e.u.]

MPC in action

• 88 demand nodes

• 63 tanks

• 114 pumping stations

• 17 flow nodes

50 100 150 200 250 300 350 400 450 500

4

5

6

7

8

Economic Cost (E.U.)

50 100 150 200 250 300 350 400 450 500

0.5

1

1.5

2

Smooth Operation Cost

0 50 100 150 200 250 300 350 400 450 500

0

2

4

6

Safety Storage Cost (× 107

)

Low price à Pumping

The system operator has

information about the

current and the

predicted operation cost.](https://image.slidesharecdn.com/effinetifacpresentation-140819051639-phpapp01/75/Water-demand-forecasting-for-the-optimal-operation-of-large-scale-water-networks-15-2048.jpg)

![5 10 15 20 25 30 35 40 45 50 55

0

20

40

60

80

100

Closed−loop MPC Simulation

Time [hr]

Repletion[%]

5 10 15 20 25 30 35 40 45 50 55

0

0.5

1

1.5

Time [hr]

Demand[m

3

/s]

MPC: Performance

10 20 30 40 50 60 70 80 90

0.2

0.4

0.6

0.8

MPC Control Action (1~20)

ControlAction

10 20 30 40 50 60 70 80 90

0.2

0.4

0.6

0.8

MPC Control Action (21~46)

ControlAction

10 20 30 40 50 60 70 80 90

0

0.1

0.2

Time [hr]

WaterCost[e.u.]

Foresight: Tanks starts

loading up before a

DMA asks for water.](https://image.slidesharecdn.com/effinetifacpresentation-140819051639-phpapp01/75/Water-demand-forecasting-for-the-optimal-operation-of-large-scale-water-networks-16-2048.jpg)