The document discusses enhanced equipment quality assurance (EEQA) and equipment health monitoring (EHM) methods to ensure reliable semiconductor manufacturing equipment. It provides:

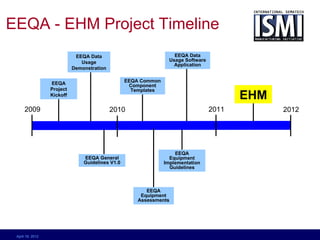

1) An overview of the EEQA and EHM projects, including goals to reduce equipment variability and efficiently track performance.

2) Details on EEQA approaches like collecting equipment data to validate functional capabilities and monitor variations.

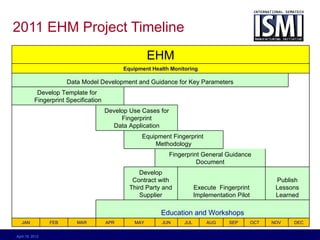

3) The 2011 EHM project timeline and objectives to demonstrate fingerprinting effectiveness using an equipment data model.

4) An equipment fingerprinting pilot to refine use cases and demonstrate the fingerprinting process using real manufacturing data.

![2011 Equipment Health Monitoring

(EHM)Project Objectives class DataSourceTypes

«XSDcomplexT ype»

DataSourceModel

Demonstrate effectiveness of data

+SourceId

1..1 1..1

+RootLocation

«XSDcomplexType»

«XSDcomplexT ype» DataSourceId

DataSourceLocation

«XSDattribute»

+ChildLocation 0..*

+ Name: Path

model usage for fingerprint scenarios

«XSDattribute»

+ Name: Path + Type: DataSourceT ype

+Dictionary

1..1

«XSDcomplexT ype»

DataSourceDictionary

Create industry guidance showing the «XSDcomplexType»

«XSDattribute»

Descriptor

application and usage of the proposed

- Description: Description [0..1]

- Key: KeyType

- Name: Name

data model for fingerprinting

+Event

0..* +Parameter 0..*

«XSDcomplexT ype» «XSDcomplexT ype»

ParameterDescriptor Ev entDescriptor

string

«XSDattribute» «XSDattribute»

+ DataT ype: ParameterDataT ype «XSDsimpleType» + Category: EventCategoryType [0..1]

+ ScalingFactor: float [0..1] ParameterValueType + SubCategory: EventCategoryType [0..1]

+ Units: ParameterUnits [0..1]

Create guidance for practical creation «XSDextension»

+ParameterRef

«XSDcomplexT ype»

0..*

and use of equipment health

ParameterRefType

«XSDattribute»

+ Key: KeyT ype

monitoring and fingerprinting of

components using the data model

Demonstrate standardized methods,

data requirements and management of

equipment health monitoring and

fingerprinting specifications

April 19, 2012](https://image.slidesharecdn.com/eeqaehmhistoryshort-13348353062109-phpapp01-120419063828-phpapp01/85/EEQA-and-EHM-Background-10-320.jpg)

![class DataSourceTypes

«XSDcomplexType»

DataSource

+Child 0..*

«XSDattribute»

+ Path: PathType

+ Type: string

«XSDtopLevelElement»

RootDataSource

1..1

+Dictionary

Equipment

«XSDcomplexType»

DataSourceDictionary Data Model

«XSDcomplexType»

Transformation

Descriptor

«XSDattribute»

+ Description: string [0..1]

+ Key: KeyType

+ Name: NameType Equipment data

+Parameter +Event

model defines

0..*

«XSDcomplexType»

0..*

«XSDcomplexType»

and correlates

ParameterDescriptor Ev entDescriptor

event and data

«XSDattribute»

+ DataType: ParameterDataType

+ ScalingFactor: float [0..1]

«XSDattribute»

+ Category: string [0..1]

+ SubCategory: string [0..1]

available in the

+ Units: UnitSymbol

equipment (raw

data) to monitor

+Trigger 0..*

«XSDcomplexType»

equipment

ParameterValueType

«XSDattribute»

health and track

+ Key: KeyType

+ Value: string

performance

April 19, 2012](https://image.slidesharecdn.com/eeqaehmhistoryshort-13348353062109-phpapp01-120419063828-phpapp01/85/EEQA-and-EHM-Background-16-320.jpg)