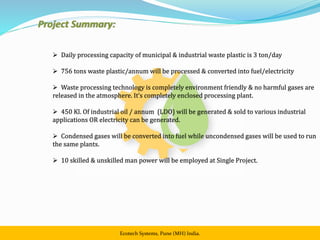

Ecotech Systems in Pune, India has developed a technology to convert plastic waste into fuel through a pyrolysis process. As little plastic is recycled globally, this process could help reduce plastic in landfills and oceans by treating plastic as a resource. The pyrolysis process uses heat and pressure to break down plastic polymers into shorter hydrocarbon chains to produce fuels like gasoline and diesel. Tests show the fuels meet Euro-III standards. Implementing this technology commercially could help address India's growing plastic waste problems while producing a profitable fuel alternative.